Catalog excerpts

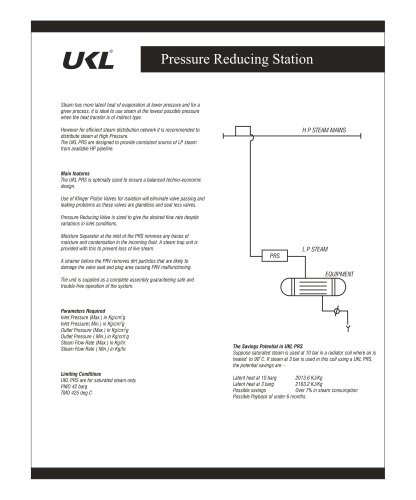

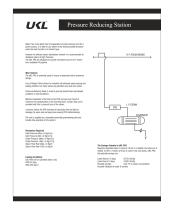

Pressure Reducing Station Steam has more latent heat of evaporation at lower pressure and for a given process, it is ideal to use steam at the lowest possible pressure when the heat transfer is of indirect type. However for efficient steam distribution network it is recommended to distribute steam at High Pressure. The UKL PRS are designed to provide consistent source of LP steam from available HP pipeline. Main features The UKL PRS is optimally sized to ensure a balanced techno-economic design. Use of Klinger Piston Valves for isolation will eliminate valve passing and leaking problems as these valves are glandless and seat less valves. Pressure Reducing Valve is sized to give the desired flow rate despite variations in inlet conditions. Moisture Separator at the inlet of the PRS removes any traces of moisture and condensation in the incoming fluid. A steam trap unit is provided with this to prevent loss of live steam. A strainer before the PRV removes dirt particles that are likely to damage the valve seat and plug area causing PRV malfunctioning. The unit is supplied as a complete assembly guaranteeing safe and trouble-free operation of the system. Parameters Required Inlet Pressure (Max.) in Kg/crrfg Inlet Pressure(Min.) in Kg/crrfg Outlet Pressure (Max.) in Kg/crrfg Outlet Pressure (Min.) in Kg/crrfg Steam Flow Rate (Max.) in Kg/hr. Steam Flow Rate (Min.) in Kg/hr. Limiting Conditions UKL PRS are for saturated steam only. PMO 42 barg TM0 425deg.C The Savings Potential in UKL PRS Suppose saturated steam is used at 10 bar in a radiator coil where air is heated to 90° C. If steam at 3 bar is used in this coil using a UKL PRS, the potential savings are -Latent heat at 10 barg 2013.6 KJ/Kg Latent heat at 3 barg 2163.2 KJ/Kg Possible savings Over 7% in steam consumption Possible Payback of under 6 months.

Open the catalog to page 1

Other Products U<L Cast / Forged Steel Piston Valves, Strainers - T Type Steam Traps - Thermodynamic, Thermostatic, Ball Float Traps, Pressure Reducing Station, Condensate Recovery Products Manual & Actuated Ball & Butterfly Valves / Bellow Sealed Valve / Level Gauges - Reflex, Transparent. Bicolor, FSD Products: Full range of Comp. Asbestos/Non Asbestos fibre Sheeting / Cut gaskets, Spiral Wound Gaskets UtL In view of technical progress designs and dimensions are subject to change without notice. UNI KLINGER LIMITED A joint venture of the Neterwala group of companies and KLINGER AG....

Open the catalog to page 2All Uni Klinger Limited catalogs and technical brochures

-

Compressed Asbestos Fiber

2 Pages

-

Expanded PTFE Sheets

2 Pages

-

Spiral Wound Gasket

4 Pages

-

Metal jacketted Gasket

2 Pages

-

Kammprofile Gasket

2 Pages

-

Non-Asbestos Gland Packing

4 Pages

-

SMU-7000 Safety Relief Valve

34 Pages

-

Compressed gasket materials

2 Pages

-

Non Asbestos Gland Packings

4 Pages

-

UCT-10 CLEAN STEAM TRAP

1 Pages

-

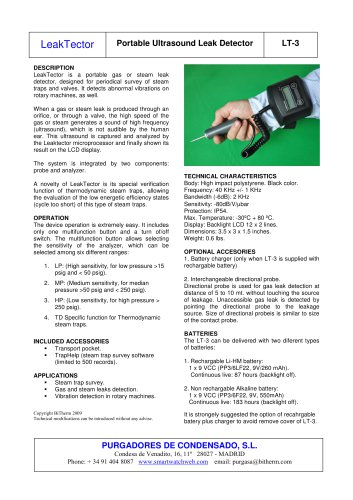

LeakTector

1 Pages

-

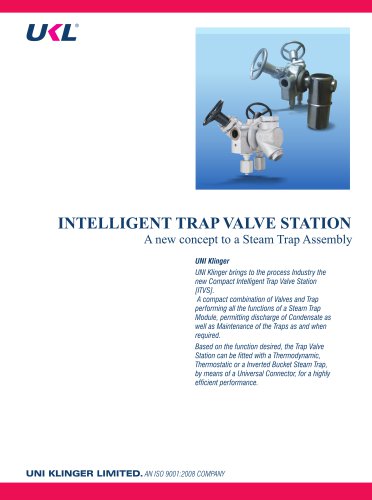

ITVS

4 Pages

-

SV-100 Safety Relief Valve

34 Pages

-

SV 200 & 300 Safety Relief Valve

15 Pages

-

AST CV-8000 Control Valve

31 Pages

-

High Pressure Valve UHPV

6 Pages

-

Bellow Seal Valves

20 Pages

-

Piston Valves

12 Pages