Catalog excerpts

Material Properties Material Description Operating Guidelines Typical Specifications Typical Original Properties (1.5mm) Typical Properties after Fluid Immersion (1.5mm) lop Quality service s/teet tor steam, gas. water, alkaline media, non-agressive sonants and many ottier clemicats sucti as aliphatic alcohols, esters, ketones and amines composed ot SBR binder and high grade chrysolite asbestos. Cofour.Red/Btom. Max. Temperature Max. Pressure (Indian Standard IS 271211998: Gr.W/1 &0/1) British German American French Minimum tensile strength (cross grain) Specific gravity Compressibility Recovery Stress relaxation Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B Top Quality universal sevice sheet suitable tor nearly all media such as. hydrocarbons, alkalines and medium strong acids. Composed of NBR binder and high grade chrysolite asbestos. Particularly suitable for use m aviation industry, hot oil and thermic fluids. Colour: Blue. T Do not retorgue fasteners at cryogenic temperatures Max. Temperature Max. Pressure Min. Temperature t (Indian Standard IS 271211998 :Gr. 01 &W/1) British German American French BS 1832 Grade A and 0 BS FI25 (types 1 and 3) DIN 3754 IT 400 DIN 3754 IT C DIN 3754 IT 0 ASJMF104-F112121M8 NFT 48001 Cat. D Minimum tensile strength (cross grain) Specific gravity Compressibility Recovery Stress relaxation Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B Top grade material based on Klingerit, but reinforced with wire mesh for Max. Temperature 550’C rftere are no standards to demanding and extreme services. Especially suitable and recommended for Max. Pressure 200’C cwer Vf<fe reinforced materials condition of fluctuating pressures and temperatures, i.e. when steam hammers might occur ot in automotive applications. Composed of SBR binder and high grade chrysolite asbestos. Delivered with graphited surfaces. Colour: Graphite black. Minimum tensile strength (cross grain) ASTMFI52 33 Nfmrrf Specific gravity 2.1 gmfcm' Stress relaxation BS 1832 31 Rimin’ As there are no standards to cover wire reinforced materials, refer to Klingerit 3XA lor typical properties Top Quality oil and petrol resistant matenal suitable for fuels, oils, sofvants including aromatic and chlorinated hydrocarbons for high mechanical and thermal demand. Excellent resistance and compatibility for natural and town gas. water, steam, aikaknes. mild acids and many other chemicals. Suitable for potable water (WRC certificabon) Composed ot chrysolite asbestos and NBR binder. Also available In metallic Colour: Black. T Do not retorgue fasteners at cryogenic temperatures High quality acid resistant material based in chrysolite asbestos and speoal binders compatible with strong organic and inorganic acids. Widely used in the chemical industry. Colour: White British BS 1832 Grade A and 0 Approved by the Water Research Council for use with potable water Minimum tensile strength (cross grain) ASTMFI52 38Nfmm2 Specific gravity 7.95 gmfcm' Stress relaxation BS 1832 30 Nfmrrf Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B Minimum tensile strength (cross grain) ASTMF152 Specific gravity Compressibility ASTMF36A Thickness increase 96% Sulphuric acid 95% Nitric acid 50% Nitric acid High quality grade similar to Klingerit widely used in the petro-chemtcal industry. Especially suitable for steam, gas. water, alkalines and other non-aggressive media. Composed for chrysolite asbestos and SBR binder Colour: Grey f Do not retorque fasteners at cryogenic temperatures French (Indian Standard IS 2712 f 1998: Gr.W/1 & 0)2) Minimum tensile strength (cross grain) ASTMFI52 30 Nfmrrf Specitic gravity 1.95 gmfcm' Stress relaxation BS 1832 29 Nfmrrf Thickness increase ASTM OH 3 ASTM Fuel A ASTM fuel B A Medium Grade Product tor hydrocarbon service, fuels and oil solutions. Good Max. Temperature 4QO'C resistance for medium pressure gases, water, steam, alkalines & acids. Colour . Black Minimum tensile strength (cross grain) AS1MFI52 22Rlmrri Stress relaxation BS 1832 2SNhm/ Thickness increase ASTM OH 3 ASTM Fuel A ASTM fuel B Good quality suitable for most applications of steam, gas. water, alcalines and other non-aggressive media under less demanding conditions. Composed of chrysolite asbestos fibre bonded with SBR. Colour: Red/Brown. Max. Temperature Max. Pressure (Indian Standard IS 2712 f 1998: W/2) Minimum tensile strength (cross grain) ASTMFI52 22 Rimin' Specilic gravity 1.95 gmfcm’ Stress relaxation BS 1832 26 Rhmf Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B Medium quality lor general purpose use. Contains chrysoMe asbestos fibre Max. Temperature 350°C British BS 1832 Grade B bonded with SBR. Also available in metallic Max. Pressure 35 tar American ASTM FI04-F112700 Cotoor. RedlBiom (Mian Standard Minimum tensile strength (cross grain) ASTMF152 13 Nfmrrf Specitic gravity 2 gmfcm’ Stress relaxation BS 1832 21 Rimin’ Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B Medium quality controlled sn«ff material extensively used by the automotive industry. Particularly suitable tor applications where bolt loadings are relatively tight ot uneven. Composed 0 ch/ysotHe asbestos fibre bonded with SBR. Colour: Yellow Minimum tensile strength (cross grain) ASTM FI52 20 Nfmrrf Specitic gravity 1.95 gmfcm’ Stress relaxation BS 1832 15 Nfmrrf Thickness increase ASTM OH 3 ASTM Fuel A ASTM Fuel B A New Grade Medium Range General Purpose Gasket Jointing For Steam. Water Max. Temperature 270C Colour: Red/Black (,ndian Standard Minimum tensile strength (cross grain) ASTMFI52 8 Nfmrrf Specific gravity 2.15 gmfcm’ Stress relaxation BS1832 14 Rimin' Thickness increase Shoots 15tTC 45% ASTM fuel A 5 hours 23’C 30% *Note: Maximum temperature and pressure capabilities do not necessarily operate together for all gasket thickness and service conditions.

Open the catalog to page 1All Uni Klinger Limited catalogs and technical brochures

-

Compressed Asbestos Fiber

2 Pages

-

Expanded PTFE Sheets

2 Pages

-

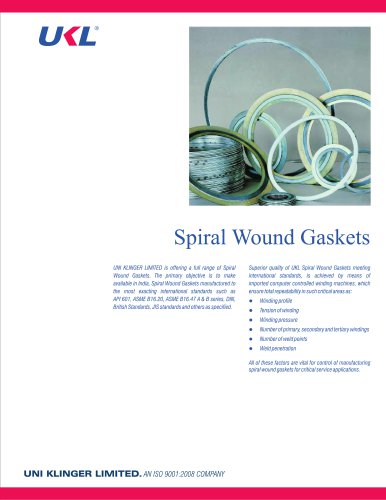

Spiral Wound Gasket

4 Pages

-

Metal jacketted Gasket

2 Pages

-

Kammprofile Gasket

2 Pages

-

Non-Asbestos Gland Packing

4 Pages

-

SMU-7000 Safety Relief Valve

34 Pages

-

Non Asbestos Gland Packings

4 Pages

-

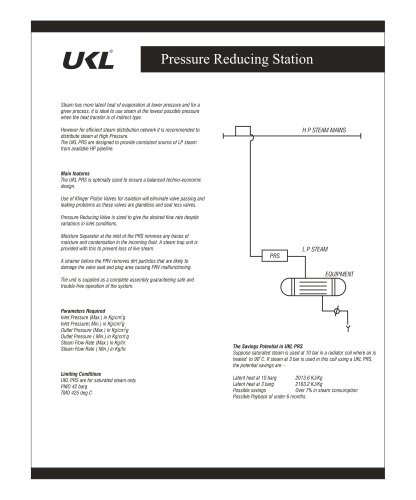

Pressure Reducing Station

2 Pages

-

UCT-10 CLEAN STEAM TRAP

1 Pages

-

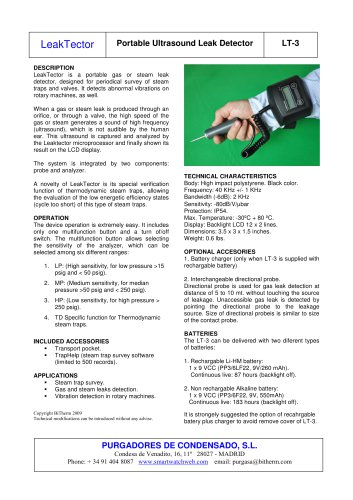

LeakTector

1 Pages

-

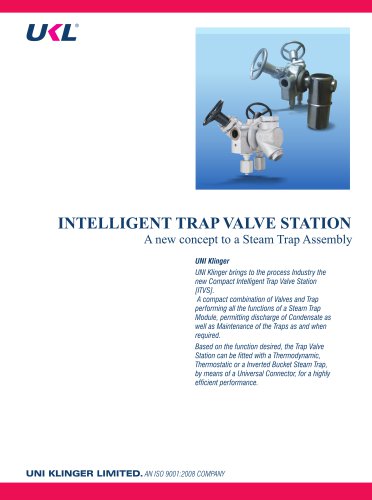

ITVS

4 Pages

-

SV-100 Safety Relief Valve

34 Pages

-

SV 200 & 300 Safety Relief Valve

15 Pages

-

AST CV-8000 Control Valve

31 Pages

-

High Pressure Valve UHPV

6 Pages

-

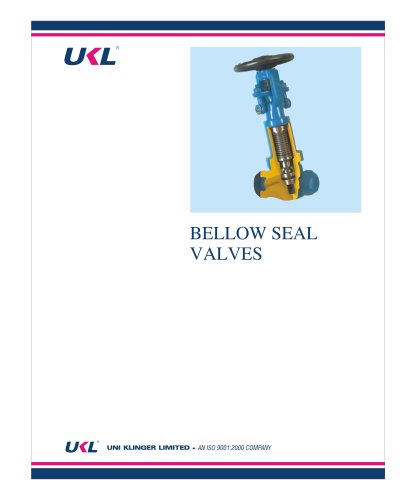

Bellow Seal Valves

20 Pages

-

Piston Valves

12 Pages