Catalog excerpts

CREATE A BETTER LIFE THROUGH OUR WORK Innovation Integrity Service Standard Vector Control Inverter Zhejiang Hechuan Technology Co.LTD WWW.HCFA.COM.CN No.9,Fucai Road, Longyou industrial Zone, Quzhou City, Zhejiang Province, P.R.C Hangzhou R&D Center Floor 4, Block D, Quzhou Overseas Haichuang Park, No.1001, Wenyi West Road, Yuhang District, Hangzhou City, Zhejiang Province, P.R.C The other products, product names, and product trademarks or registered trademarks described in this manual are owned by each company. All information in this document is subject to change without notice. Manual No.; September, 2021 Issue No. 5

Open the catalog to page 1

To be the most valuable industrial automation core components and solutions provider T he pro d u cts are wide ly u sed in O E M fie lds suc h as p h otovolta ic , 3 C, lith iu m batte ries, ro b ots , pac kag i n g , textile s, lo gistic s, lase rs, m a c h i n e too l, etc . Sales Offices Global Distributors Sales elites gathering Products sold worldwide

Open the catalog to page 2

More reliable General-purpose control board, keyboard panel and extension card Extend main parts’ life, 100%PCB coating. Powerful function Conformal coating Greatly improve the capability of insulation, moisture-proof, leakage prevention, dustproof, anti-corrosion, anti-aging, anti-mildew etc. Excellent overvoltage suppression capability, Fast acceleration/ deceleration, Over-current protect function Exquisite appearance Independent heat dissipation channel Effectively prevent environmental impact on products and extend products’ lifetime greatly. anticorrosion Dust-proof Space reduced by...

Open the catalog to page 3

Technical specifications Items Individualized functions Load feedback energy compensates for any voltage reduction, allowing the inverter to continue to operate for a short time during power dips Dual-motor switchover The inverter have two groups of motor parameters and can control up to two motors Timing control Multiple fieldbus supported Motor overheat protection Multiple encoder types supported Command source Main frequency reference setting channel Auxiliary frequency reference setting channel Input terminals Output terminals Display and operating panel Parameter copy Timing control:...

Open the catalog to page 4

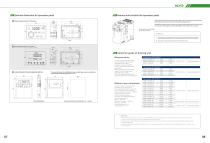

Main structures diagram Product installation size Operation panel Model name Terminal cover I/O wiring terminal Mounting hole Mounting hole Nameplate Ventilation slit Mounting hole External dimensions mm Mounting Weight mm hole mm kg W1 H1 H W D External dimensions Operation panel introduction Unit indicator STOP RESET STOP RESET STOP RESET Turn button Forward rotation operation Flicker: Serial communication control FWD REV REM STOP RESET H C FA Forward rotation indicator Reverse rotation indicator Off: Panel control Hz:Frequency A:Current V:Voltage Data display The outline drawing and...

Open the catalog to page 5

External dimension for operation panel External dimension for LED panel Remove and reinstall the operation panel 48.5 STOP RESET Press inwards on both sides to release the panel Remove the operation panel: Put the middle finger to the slot at the upper side of operation panel and press inwards on both sides to release the operation panel. The machine is equipped with LED panel and support external extension. Note whenpurchasing and the external extension cable can be provided External dimension for LCD panel LCD panel is optional and can be extended externally STOP RESET Cutout dimension for...

Open the catalog to page 6

Inverter installation Standard wiring for three-phase 220V inverter Short-circuited copper Install the inverter indoors, with good ventilation, and generally vertically. The installation clearance that need to be reserved is shown as below. Installation environment Mounting direction and clearance Single-inverter installation The ambient temperature should be around -10℃~40℃. Whentemperature exceeds 40℃, the external forced cooling or de-rating is required. Installation above another inverter Install the inverter on the surface of an incombustible object, and ensure that there is sufficient...

Open the catalog to page 7

Selection Guide Model name [Models of 2.2kW or less support single phase operation] Input voltage Input terminal Function description 1) Control mode: No PG vector speed control, No PG vector torque control★, PG Standard: vector speed control★, PG vector torque control★, V/F control 2) Timing control function: 0.0‒6500.0 minutes 7 digital input terminals, 3) Instantaneous power-failure: Load feedback energy compensates for any voltage one terminal support at reduction, allowing the drive to continue to operate for a short time during power dips most 100kHz high-speed 4) Multi-motor...

Open the catalog to page 8

Differential input wiring diagram Push-pull input wiring diagram Step 1: Connect the output signal of the encoder to the A+/A-, B+/B-, Z+/Z- of the input terminal of the PG card respectively, and connect the power of the encoder to the terminal 5/15; Step 1: If it is a push-pull differential output encoder, please connect the encoder output A-/B-/Z-phase to the A-/B-/Z- of the PG card input terminal respectively, and no connection for the encoder output A+/B+/Z+ phase: If it is a push-pull single-ended signal output, please connect the encoder signal A-/B-/Z-phase to the A-/B-/Z- of the PG...

Open the catalog to page 9

Relationship between encoder cable length and cables The longer the encoder cable, the greater the cable resistance, so the encoder power supply and encoder signal voltage drop across the cable resistance will be greater. For long-distance applications, if the wire gauge selection is unreasonable, the encoder and PG will not work normally due to the signal attenuation caused by the cable resistance. Please refer to the table below to select the appropriate wire gauge based on the length of the on-site cable (wire gauge: the standard for distinguishing wire diameters, here use AWG). Cable...

Open the catalog to page 10All UMOTO HCFA catalogs and technical brochures

-

HCFA Q-series

2 Pages

-

X2EX3E Servo Catalog

36 Pages

-

X5EX6 Servo Catalog

32 Pages

-

Control Products Catalog

48 Pages