Website:

ULT

Website:

ULT

Catalog excerpts

Extraction and Filtration Technology for Soldering Fumes ULT UMWELT- LUFTTECHNIK Extraction. Filtration. Persistence.

Open the catalog to page 1

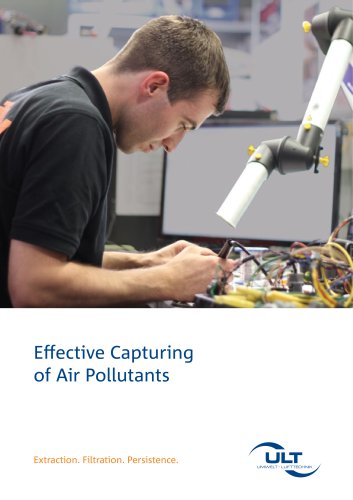

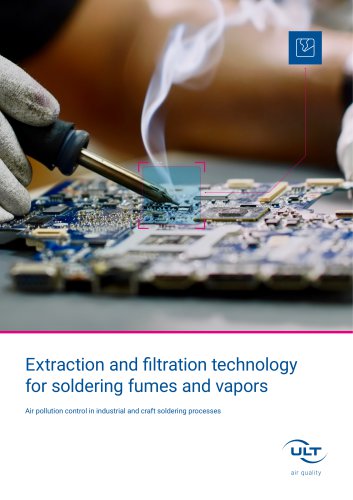

Whether manual workstations or automated production line, soldering workstations may only be operated with properly working fume extraction technology.

Open the catalog to page 2

An automated electronics production line creates many thousands of solder joints per hour, a craftsman will perhaps only make ten of them in the same time. However, all soldering processes emit fume and this fume is anything but harmless. Soldering fumes Substances that are perceived as soldering fumes are decomposition products from flux, soldering alloys and residues of cleaning agents, which often join up to tacky aerosols. These airborne pollutants may impose adverse effects on human health, therefore, legal regulations on the removal of soldering fumes from the air at workplaces are...

Open the catalog to page 3

Fume extraction with graded performance levels. Filtration system Type LRA devices are saturation filter units. Complex filter systems retain dusts, gaseous pollutants and aerosols. The purified air can then be re-circulated back into the working room, greatly enhancing energy management. To precisely capture pollutants, extraction and filtration units may be equipped with suitable extraction arms and collecting elements. For this purpose ULT offers high quality products from leading suppliers. Saturated storage filters are easily exchanged and can partly be refurbished. Due to innovative...

Open the catalog to page 4

LRA fume extraction technology includes a wide range of units, graded for air capacity. The offerings extend from small, ergonomically designed mobile units for individual workstations to high performance systems for automated or semi-automated production lines. Some models can be optimized for special operating conditions, e.g. strong smoke emission or large amounts of certain harmful substances by exchanging or adding filtration modules. To eliminate odors, suitable adsorbents such as activated carbon are used. LRA series Volume Vacuum Nominal

Open the catalog to page 5

LRA stands for sophisticated production devices of fume extraction units for soldering workplaces - modularly designed according to user requirements. If needed, they allow for an optimized adaptation to respective operating conditions and become an integral part of the production plants. Particularly user friendly Low noise level and low energy consumption. Simple operation and maintenance. Air recirculation operation possible. Easy filter exchange - no protective measures required. Tailored solutions: from compact to large ULT's solutions range from mobile units for individual workplaces...

Open the catalog to page 6

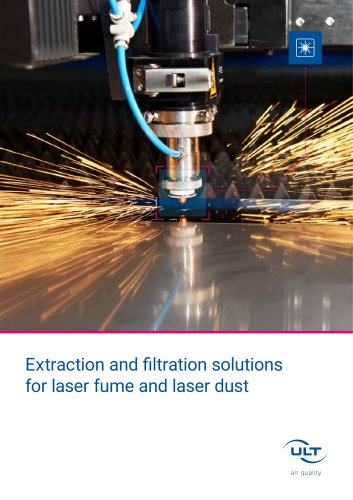

ULT AG provides fume extraction technology that really works: in-house developed excellent serial units, adapted to individual requirements by sophisticated engineering. From single workplaces to hall solutions. Permanent research ensures that even the latest production processes are safely served. LASER DUST FUMES AND SMOKE SOLDERING ODORS, FUMES GASES, AND MANUFACTURING WELDING FUMES cOMPLETE SOLUTIONS Based on sophisticated series devices, ULT AG provides adapted fume extraction solutions 7

Open the catalog to page 7

ULT AG Am Göpelteich 1, 02708 Löbau, Germany Phone: +49 (0) 3585 4128-0 Fax: +49 (0) 3585 4128-11 Hotline: +49 (0) 800 8582400 E-mail: ult@ult.de ULT is certified according to ISO 9001:2015. The plants are designed according to international standards. If required, they will be certified according to ATEX and W3 and tested to meet H requirements. In addition, the plants always comply with current EC directives on energy efficiency (ErP directive: Total energy efficiency of ready-to-use ventilation systems or minimum energy efficiency of electric motors). Detailed technical information can...

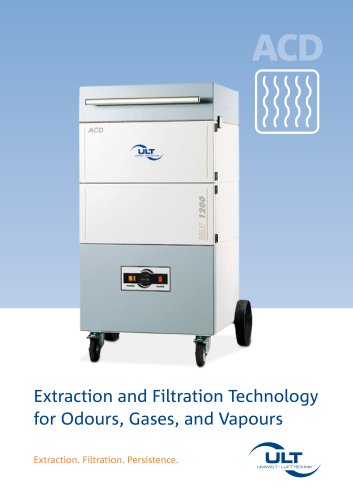

Open the catalog to page 8All ULT catalogs and technical brochures

-

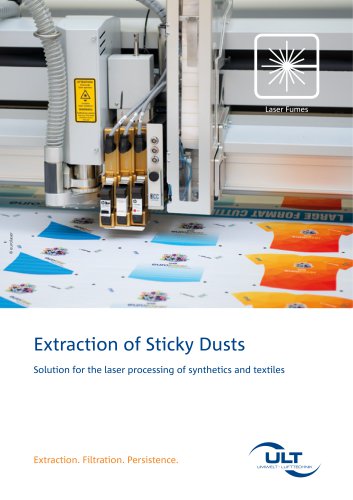

Extraction of Sticky Dusts

2 Pages

-

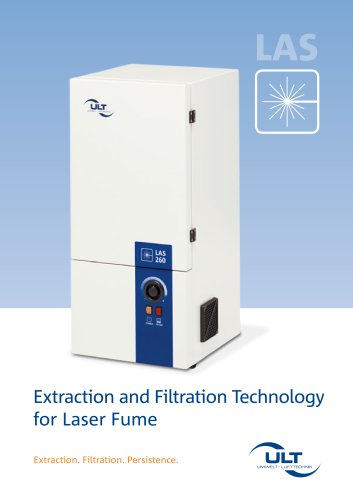

Laser fume extraction systems

12 Pages

-

Product Overview

6 Pages

-

JUMBO Filtertrolley Elephant

2 Pages

-

LRA Series

8 Pages

-

ASD 300 ex

2 Pages

-

LRA for soldering smoke

6 Pages

-

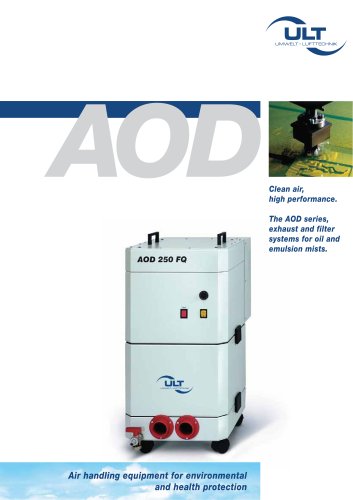

ASD for dust and smoke

6 Pages

-

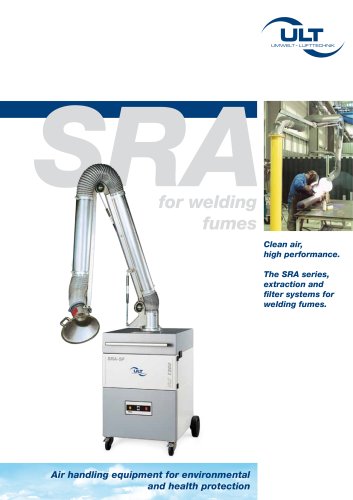

SRA for welding fumes

6 Pages

-

ULT Product Overview

2 Pages

-

Jumbo Filtertrolley

6 Pages

-

LAS for laser smoke

12 Pages