Catalog excerpts

Extraction and Filtration Technology for Dust and Smoke ULT UMWELT- LUFTTECHNIK Extraction. Filtration. Persistence.

Open the catalog to page 1

Many production processes release dust and smoke. In most cases, functional extraction and filtration technology is required.

Open the catalog to page 2

When handling powdery materials during production processes, e.g. during grinding or filling, dust will inevitably be released. The same applies, when plastics, stone or metal material get sawn, milled or abraded. In addition, often smoke and gases are released. Modern techniques, such as additive manufacturing, release blends of particulates. Dust and Smoke Dust can cause respiratory and eye disease. The finer its granularity, the more harmful are its effects, as those particles can penetrate into pulmonary alveoli and overcome the lung-blood barrier. Therefore, legal regulations on the...

Open the catalog to page 3

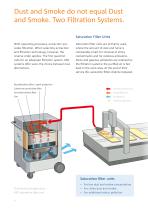

Dust and Smoke do not equal Dust and Smoke. Two Filtration Systems. Saturation Filter Units With operating processes, extraction precedes filtration. When selecting extraction and filtration technology, however, the reverse order applies. The first question calls for an adequate filtration system. ASD systems offer users the choice between two alternatives. Saturation filter units are primarily used, where the amount of dust and fume is comparably small, for removal of sticky contaminants and for odorous emissions. Dusts and gaseous pollutants are retained by the filtration systems; the...

Open the catalog to page 4

Cartridge filter units are mainly used to remove dry, concentrated dust and smoke in rather high volumes. They feature long service life and low operating costs. Pollutants are collected on the surface of the filter cartridge. The filter cartridge is cleanable. At intervals, the cartridge gets cleaned with a compressed air counter-flush and the dust is completely gathered in dust bins. Purified air is fed back into the work area. Process exhaust air Pollutant particle Purified air Particles blown off Dedusting air blast Compressed air tank Cartridge filter units » For high dust and smoke...

Open the catalog to page 5

Type and volume of dust and smoke are not the sole criteria when selecting the adequate filter system. The required extraction capacity is also of key importance. Work place and extraction environment are essential here: How close can I get to the point of pollution generation? What volume capacity shall be extracted? How far must the exhaust air be transported? ASD saturation filter units are primarily designed for low to medium dust and smoke intensity. They are suitable for numerous single-user workstations in labs, manufacturing or industry. The normally small footprint of saturation...

Open the catalog to page 6

ASD series Volume Vacuum Nominal For high dust and smoke concentration ASD cartridge filter units are the devices of choice. Due to integrated dust collectors they require slightly more space than saturation filter units. The highest-performing units are stationary devices. In their most sophisticated configuration levels they are perfectly suited for extraction at large or central systems and efficiently remove high volumes of dust and smoke. Examples for cartridge filter systems: ASD 300 (left), ASD 300 Ex (middle) and ASD 500 (right)

Open the catalog to page 7

Critical: Proximity, Geometry Quality of pollutant collection is the linchpin of extraction and filtration technology. In particular, closest proximity to the source of pollution is of critical importance: Doubling the distance, for example means a fourfold increase in required suction capacity and an exponential increase in energy consumption, to collect the corresponding amount of particles. In general, the type of capturing element used must best suit the selective extraction situation at each respective work place. This is a question of both geometry and dimensions. Raw gas Extraction...

Open the catalog to page 8

Individual Capturing Elements ULT selects the type of capturing element that best suits the selective extraction situation at the respective work place from the portfolios of leading suppliers. Often, the design will be adapted, to come to grips with the discharge impulse of pollution particles. Adaptations cover a variety of solutions, ranging from suction tips and hoods to complete housing of the source of pollution. Naturally, total solutions include suitable extraction arms. Flat hood Suction funnel Spherical curved hood Angular curved hood Selection of capturing elements

Open the catalog to page 9

ASD: Perfect Serial Products. Built on Sophisticated Engineering. ASD stands for sophisticated production devices of extraction and filtration units for dust and smoke – organized in modules according to user requirements. If needed, they allow for an optimized adaptation to respective operating conditions and become an integral part of the production plants. From compact to large ULT’s solutions range from mobile equipment for individual work places to complete solutions for entire production facilities. Also for environments with a lack of space. Particularly user friendly Low noise level...

Open the catalog to page 10

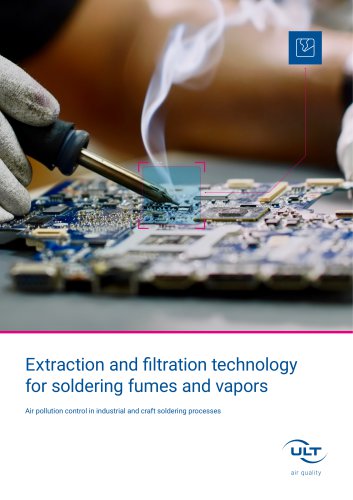

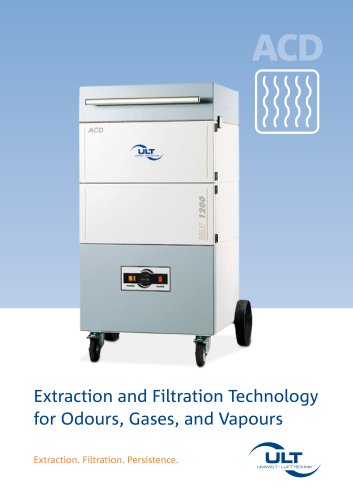

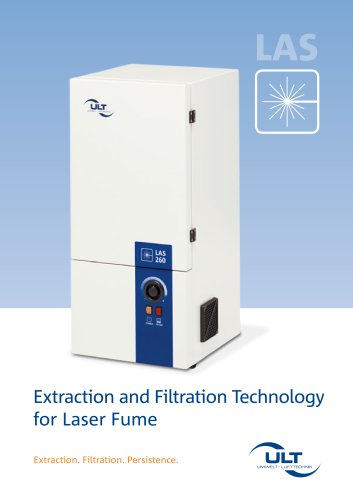

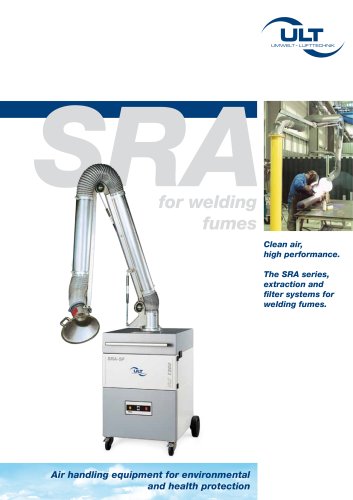

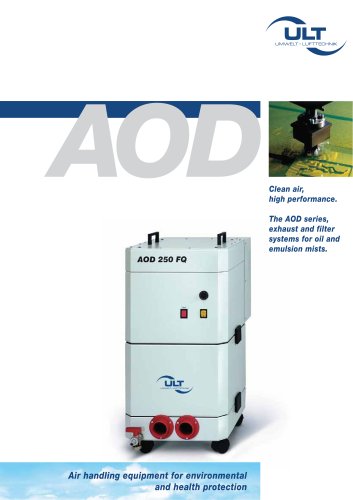

ULT AG ULT AG provides extraction and filtration technology that really works: in-house developed excellent series units, adapted to individual requirements by sophisticated engineering. Laser Fumes Soldering Fumes Odours, Gases, and Vapours From single work places to hall solutions. Permanent research ensures that even the latest production processes are safely served. Welding Fumes Complete Solutions Based on sophisticated series devices ULT AG provides adapted solutions for extraction and filtration technology.

Open the catalog to page 11

ULT is certified according to ISO 9001:2015. The plants are designed meeting international standards. If required, they will be certified according to ATEX and W3 and tested to meet H requirements. In addition, the plants always comply with current EC directives on energy efficiency (ErP directive: Total energy efficiency of ready-to-use ventilation systems or minimum energy efficiency of electric motors). Detailed technical information can be found on device specific data sheets or on our website All technical data is general and not binding and does not guarantee the suitability of a...

Open the catalog to page 12All ULT catalogs and technical brochures

-

Extraction of Sticky Dusts

2 Pages

-

Laser fume extraction systems

12 Pages

-

Product Overview

6 Pages

-

JUMBO Filtertrolley Elephant

2 Pages

-

LRA Series

8 Pages

-

ASD 300 ex

2 Pages

-

LRA for soldering smoke

6 Pages

-

ASD for dust and smoke

6 Pages

-

SRA for welding fumes

6 Pages

-

ULT Product Overview

2 Pages

-

Jumbo Filtertrolley

6 Pages

-

LAS for laser smoke

12 Pages