Website:

ULT

Website:

ULT

Catalog excerpts

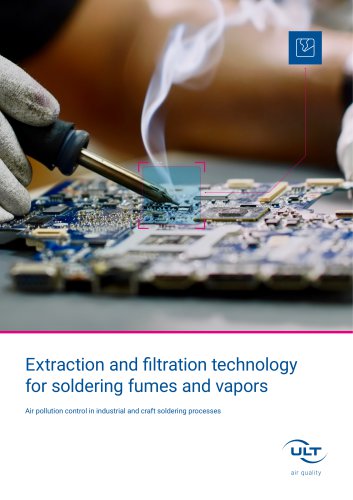

Extraction and filtration technology for soldering fumes and vapors Air pollution control in industrial and craft soldering processes

Open the catalog to page 1

Soldering processes and applications Soldering processes are utilized in a wide range of industrial and craft sectors. It is an important and versatile technology for joining primarily metallic parts together, thus enabling the manufacture of various products. SOLDERING PROCESSES ARE UTILIZED IN: • Electronics manufacturing • Machinery and metalworking • Aviation and aerospace • Construction industry • Jewelry making • Instrument making • Arts and crafts • and more CURRENTLY APPLIED SOLDER PROCESSES: • Dip soldering • Piston soldering •W ave soldering • Reflow soldering • Selective...

Open the catalog to page 2

Technologies and emissions Soldering processes are also subdivided according to the liquidus temperature of the solder and are used in different areas: SOFT SOLDERING HARD SOLDERING HIGH TEMPERATURE SOLDERING Liquidus temperature •C opper and copper alloys • Sheet steel • Aluminum • Zinc • Stainless steel • Steel • Brass • Copper • Silver (alloys) • Gold (alloys) • Stainless steel • Nickel • Cobalt • Ceramics Application examples • Electronics manufacturing • Electrical installation • Sanitary engineering •J ewelry and handicrafts • Heating construction • Instrument making • Plumbing...

Open the catalog to page 3

Health risks and legal basis In many countries there are a number of legal regulations that prescribe how airborne pollutants in the process air must be removed. A distinction is made as to whether the substances are harmful to the brain, nerves or respiratory tract, or whether they are inhalable or alveolar. Material processing releases pollutants 100 μm COARSE DUST 10 μm FINE DUST 1 μm 0.1 μm FINEST DUST AND SMOKE The exact composition of the soldering fume depends on various factors, e.g. the solder used, flux, soldering temperature, and soldered materials. Therefore, an analysis of the...

Open the catalog to page 4

Pollutant collection The filtration process begins with the capture Air pollutants are collected before filtration, because only what is captured can be filtered. The degree of capture forms the basis for the subsequent optimal filtration. Consequently, this results in the efficiency of the entire system and therefore the pollutant residues in the recirculated exhaust air. The greatest proximity to the pollutant source is crucial here. The selection of the best-suited collection element is also of great importance. ULT is at the customer's side to provide advice. Further information on the...

Open the catalog to page 5

Separation principle storage filters Storage filter systems are almost exclusively used to remove soldering fume and vapor. BENEFITS: • Low investment and operating costs • High flexibility • Easy maintenance • High separation performance • Compact, often modular design Extraction and filtration technology for soldering fumes and

Open the catalog to page 6

ULT systems for soldering fume extraction ULT offers a wide range of mobile and stationary systems for solder fume extraction. Depending on the application, the modular extraction systems of the LRA series can be expanded or adapted. ULT is happy to advise its customers on this. Based on our extensive experience, we know that every process needs to be analyzed specifically. Different parameters play a role that are crucial for selecting the optimum filtration device. Storage filter systems Thanks to the specially developed “Silent Technology”, ULT’s extraction and filtration systems are...

Open the catalog to page 7

The right plant design for optimum air pollution control The dimensioning of the plant technology is derived from a fundamental analysis of the production and pollutant situation. This should be prepared by experts together with the users 3) T RANSMISSION ELEMENT DETERMINING Extraction and filtration technology for soldering fumes and vapors 4) D EVICE AND TECHNOLOGY DETERMINING 5) W ASTE HANDLING AND MAINTENANCE

Open the catalog to page 8

Intelligent solutions for best air quality ULT — air quality Since the air quality is of fundamental importance for work and production processes, ULT as a full-service provider, develops air purification solutions for the highest demands — to protect employees, equipment, products, and the environment. The reliability of our products ensures manufacturing processes and the profitability of our customers. The proximity of the ULT experts to the processes and requirements of our customers enables the development of tailor-made and needs-oriented solutions — from standard products to...

Open the catalog to page 9

Solder fume extractor LRA 1200 utilized for automated soldering processes Solutions — unique and customer-oriented What makes our solutions for soldering fume extraction special: ·C omplete system solutions: filter types, safety technology, accessories ·L ow-noise operation · Low operating costs Extraction and filtration technology for soldering fumes and vapors EXTRACTION SYSTEMS FOR SOLDERING FUME AND VAP

Open the catalog to page 10

Information on the practical use of ULT air technology for solder fume extraction can be found in our ULT Expert Center. ULT EXPERT CENTER

Open the catalog to page 11

ULT AG Am Göpelteich 1 02708 Löbau, Germany Phone: Fax: E-Mail: Web:

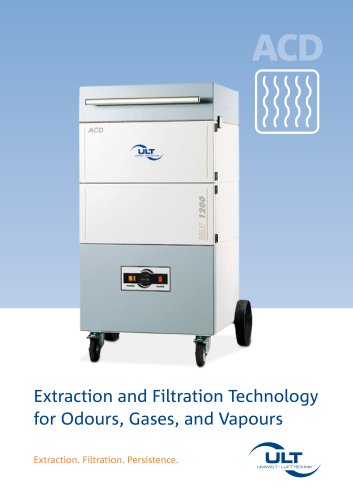

Open the catalog to page 12All ULT catalogs and technical brochures

-

Extraction of Sticky Dusts

2 Pages

-

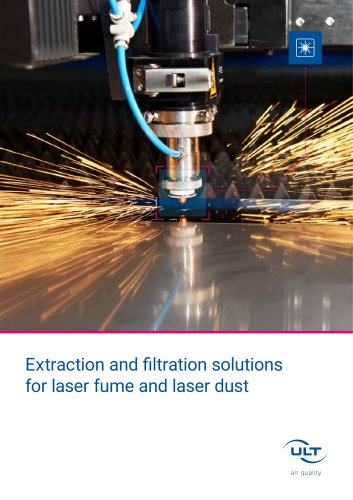

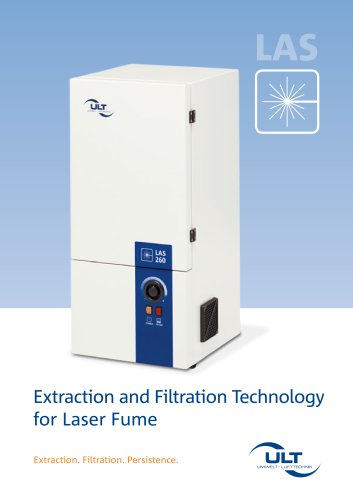

Laser fume extraction systems

12 Pages

-

Product Overview

6 Pages

-

JUMBO Filtertrolley Elephant

2 Pages

-

LRA Series

8 Pages

-

ASD 300 ex

2 Pages

-

LRA for soldering smoke

6 Pages

-

ASD for dust and smoke

6 Pages

-

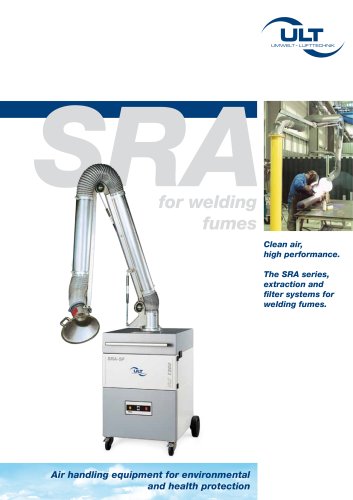

SRA for welding fumes

6 Pages

-

ULT Product Overview

2 Pages

-

Jumbo Filtertrolley

6 Pages

-

LAS for laser smoke

12 Pages