Catalog excerpts

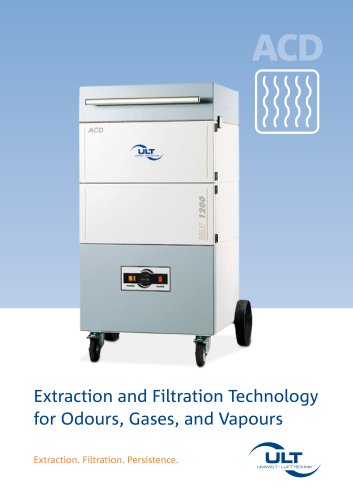

Extraction and Filtration Technology Extraction. Filtration. Persistence. UMWELT- LUFTTECHNIK

Open the catalog to page 1

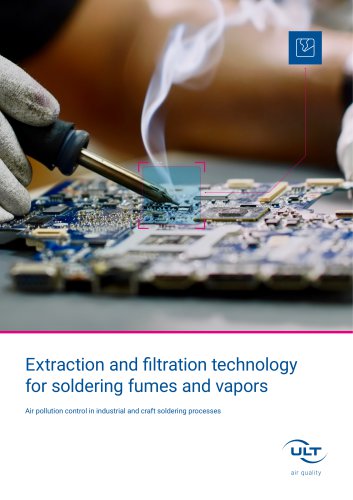

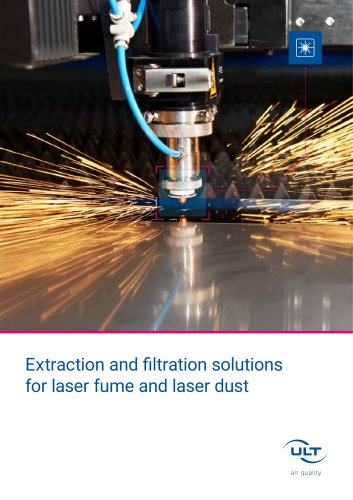

Laser Technology is Great. When it has Given up Smoking. Lasers are welding metal or plastic compo nents, they are cutting sophisticated con tours and they are marking and structuring surfaces. Also printing and medical technol ogies benefit from laser technologies. But all of them share one problem: laser fume. are operated in highly automated volume production environments, a high degree of availability is of concern. ULT’s extraction and filtration technology LAS for laser fume removal meets all these requirements. Laser Fume No matter, whether processed materials are harmless — laser...

Open the catalog to page 2

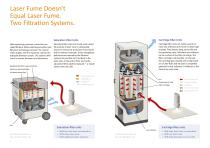

Laser Fume Doesn’t Equal Laser Fume. Two Filtration Systems. Saturation Filter Units With operating processes, extraction pre cedes filtration. When selecting extraction and filtration technology, however, the reverse order applies. The first question calls for the adequate filtration system. LAS systems offer users to choose between two alternatives. Resublimation filter / spark protection Cartridge Filter Units Saturation filter units are mainly used, where the amount of laser fume is comparably small, for removal of sticky laser fume shares and for odorous emissions. Dusts and gaseous...

Open the catalog to page 3

Also Essential: Extraction Capacity. Type and volume of the laser fume aren’t the sole criterion when selecting the adequate filter system. The required extraction capacity is also of key importance. Work place and suction environment are essential here. LAS saturation filter units are primarily design ed for low to medium laser fume intensity. They are suitable for numerous single-user workstations in labs, manufacturing or indus try. The normally small footprint of saturation filter units brings some advantages into play: compact and mobile solutions. Saturation filter units: LAS 1200,...

Open the catalog to page 4

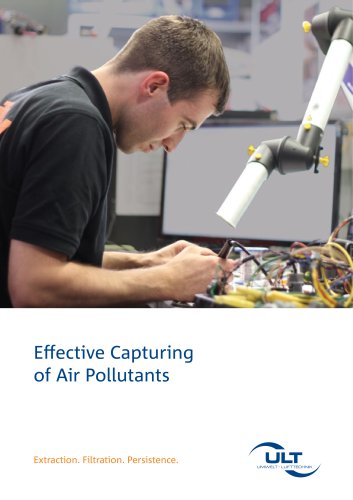

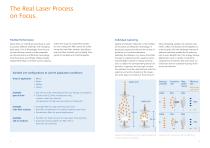

The Real Laser Process on Focus. Individual Capturing Quite often, an individual work place is used to process different materials with changing laser tools. Or it is foreseeable from the out set that the laser system will be expanded and the extraction and filtration technology must then grow accordingly. Simple module replacement helps to increase suction capa ity c within the range of a given filter system. Or even change the filter system by substi tuting the main filter module. Special preand post-filter modules can be added. Also capturing modules are interchangeable. Variable unit...

Open the catalog to page 5

LAS: Perfect Serial Products. Built on Sophisticated Engineering. ULT AG LAS stands for a sophisticated series of units organised in modules according to user requirements. Smart engineering concepts enable a perfect adaptation to individual local demands making the units an integral part of the production equipment. Tailored solutions: from compact to large ULT’s solutions range from mobile equip ment for individual work places to complete solutions for entire production halls. Solutions for environments with lack of space included. Particularly user friendly Low noise level and low...

Open the catalog to page 6

ULT AG Am Göpelteich 1, 02708 Löbau, Germany Phone: +49 (0) 3585 4128-0 Fax: +49 (0) 3585 4128-11 Hotline: +49 (0) 800 8582400 E-mail: ult@ult.de ULT is certified according to ISO 9001:2008. The plants are designed according to inter national standards. If required, they will be certified according to ATEX and W3 and tested to meet H requirements. In addition, the plants always comply with current EC directives on energy efficiency (ErP directive: Total energy efficiency of ready-to-use ventilation systems or minimum energy efficiency of electric motors). Detailed technical information can...

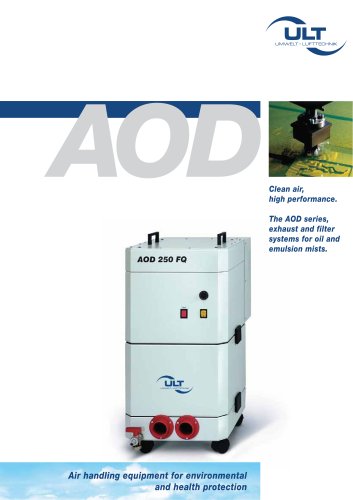

Open the catalog to page 7All ULT catalogs and technical brochures

-

Extraction of Sticky Dusts

2 Pages

-

Laser fume extraction systems

12 Pages

-

Product Overview

6 Pages

-

JUMBO Filtertrolley Elephant

2 Pages

-

LRA Series

8 Pages

-

ASD 300 ex

2 Pages

-

LRA for soldering smoke

6 Pages

-

ASD for dust and smoke

6 Pages

-

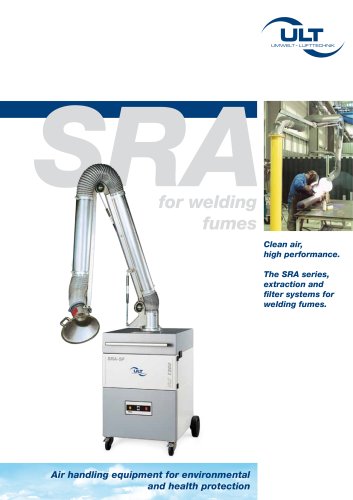

SRA for welding fumes

6 Pages

-

ULT Product Overview

2 Pages

-

Jumbo Filtertrolley

6 Pages

-

LAS for laser smoke

12 Pages