Website:

ULT

Website:

ULT

Catalog excerpts

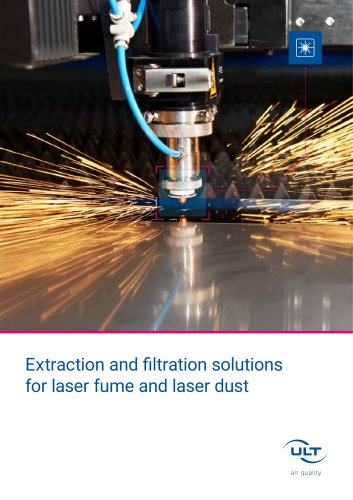

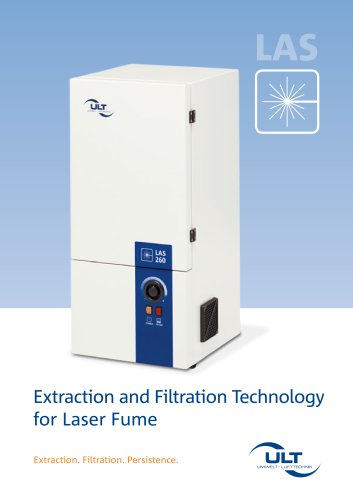

Extraction and filtration solutions for laser fume and laser dust

Open the catalog to page 1

Laser processes and applications The use of laser technology has become standard in many industrial manufacturing processes, but also in other areas such as medical technology or R&D. Cutting and joining processes, surface processing, marking or modern production technologies such as additive manufacturing benefit from the extensive advantages of this technology. There is not "the" laser, because the range of possible technologies is also increasing. Application fields Processes materials · Laser cutting · Laser sintering · Laser welding · Laser marking · Laser structuring · Laser ablation...

Open the catalog to page 2

Laser wavelengths in the electromagnetic spectrum INVISIBLE SPECTRUM (ULTRA VIOLET) 100 nm – 380 nm INVISIBLE SPECTRUM (NEAR INFRARED) 780 nm – 2,500 nm INVISIBLE SPECTRUM (INFRARED) 2,500 nm – 1 mm UV LASER ·1 93 nm: Applications in medical technology, e. g. eye treatments · 355 nm: Laser marking, cutting, structuring of e. g. copper, glass, ceramics ·4 50 nm: UV laser for laser marking, cutting of plastics, wood VISUAL LASER ·5 32 nm: High-precision turning or cutting of a wide variety of materials, e. g. saphire, glass, and metal · Melting, welding of copper and gold NEAR INFRARED LASER...

Open the catalog to page 3

Technologies and emissions Long pulse laser Ejected material Surface debris Damaged surface Recast layer Micro cracking Melt zone Shock waving Heat transfer to surrounding material Ultra short pulse laser No damaged surface No debris No recast layer Plasma plume No micro cracking No shock waving No melt zone Laser fume extraction technologies Hot, dense ion/electron soup

Open the catalog to page 4

Depending on the laser technology, all applications produce airborne pollutants, classically referred to as laser fume, laser dust or laser vapor. These emissions consist of particles of different sizes and compositions. They may have impacts on the human organism, the manufacturing equipment, and the product quality. The type of contaminant emission depends on the respective laser process. Particle shapes after processing with different laser techniques. Sedimentation behavior of airborne particles The finer the laser dust, i.e. the smaller the particles produced, the longer it takes for...

Open the catalog to page 5

Health risks and legal basis In many countries there is a number of legal regulations that prescribe how airborne pollutants in the process air must be removed. A distinction is made as to whether the substances are harmful to the brain, nerves or respiratory tract, or whether they are inhalable or alveolar. Material processing releases pollutants 100 μm COARSE DUST 10 μm FINE DUST 1 μm 0.1 μm FINEST DUST AND SMOKE Some compositions of laser fume, e. g. chromiumnickel compounds, must be considered separately, as special occupational safety regulations apply to them. The use of professional...

Open the catalog to page 6

Pollutant collection The filtration process begins with the capture Air pollutants are collected before filtration, because only what is captured can be filtered. The degree of capture forms the basis for the subsequent optimal filtration. Consequently, this results in the efficiency of the entire system and therefore the pollutant residues in the recirculated exhaust air. The greatest proximity to the pollutant source is crucial here. The selection of the best-suited collection element is also of great importance. ULT is at the customer's side to provide advice. Further information on the...

Open the catalog to page 7

Filter types and particle sizes GASES/ODORS 0.0001 μm STORAGE FILTERS SORPTION FILTERS (ACTIVATED CARBON/CHEMISORPTION) Filtration principles STORAGE FILTER ·F or low laser fume concentration and sporadic use ·L ow investment costs ·H igh flexibility Laser fume extraction technologies CARTRIDGE FILTER ·F or higher laser dust concentrations and continuous use ·L ow maintenance requirement ·H igh operating point stabilit

Open the catalog to page 8

The right plant design for optimum air pollution control The dimensioning of the plant technology is derived from a fundamental analysis of the production and pollutant situation. This should be prepared by experts together with the users 3) T RANSMISSION ELEMENT DETERMINING 4) D EVICE AND TECHNOLOGY DETERMINING 5) W ASTE HANDLING AND MAINTENANCE

Open the catalog to page 9

Utilization of additional technology In certain cases, a "simple" extraction and filter system is no longer sufficient. For example, in the case of moist laser dust from plastics or organic materials such as paper or wood, a filter aid additive is necessary in almost all cases. This supports and optimizes the separating process of the occurring particles and, hence, extends the filter life considerably. FILTER AID FOR PARTICLE SEPARATION In addition, laser processes almost always generate odors or gases, which can be removed by appropriate sorption processes (use of activated carbon or...

Open the catalog to page 10

Undesirable dangers — what should be considered? Question: What pollutants are produced? The Gestis database of the DGUV provides necessary information. DGUV GESTIS DATABASE Based on hazardous material checklists and risk assessments, we develop a comprehensive concept for your ideal extraction and filtration solution. Analysis stage and questions Structural analysis Functional analysis Fault analysis Are the substances flammable or explosive? Which explosion protection zones are there? Are spark traps or filter aids necessary? What laws and guidelines must be followed? What are the...

Open the catalog to page 11

ULT systems and their typical fields of application The applications below are exemplary and show the currently common process technologies — others such as laser melting, laser ablation or micro-processing are also supported by partly special system configurations in consultation with users. For this purpose, ULT is there to advise its customers. Based on extensive practical experience, we know that each process must be analyzed specifically. Parameters such as laser power, dust quantity and the amount of required air play decisive roles. Storage filter systems Typical fields of...

Open the catalog to page 12All ULT catalogs and technical brochures

-

Extraction of Sticky Dusts

2 Pages

-

Laser fume extraction systems

12 Pages

-

Product Overview

6 Pages

-

JUMBO Filtertrolley Elephant

2 Pages

-

LRA Series

8 Pages

-

ASD 300 ex

2 Pages

-

LRA for soldering smoke

6 Pages

-

ASD for dust and smoke

6 Pages

-

SRA for welding fumes

6 Pages

-

ULT Product Overview

2 Pages

-

Jumbo Filtertrolley

6 Pages

-

LAS for laser smoke

12 Pages