Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Group: Uhlmann Group

Catalog excerpts

Blister machine B 1880 with intermittent platen sealing The fastest blister machine in the world sets new standards in pharmaceutical production with every detail. Award-winning high tech The Blister machine B 1880 is based on established high- The B 1880 with intermittent platen sealing is the ideal blister performance machines and is available in the versions technology for drawing depths up to 12 mm. The principle of multiple-stroke intermittent sealing and multiple-stroke intermittent sealing with platen tools is particularly suitable continuous sealing. It combines forward-looking, innovative for the processing of special lid foils and paper laminates, i.e. machine design with GMP compliancy, simple operation, top for so-called peel or peel-push blisters. Predestined for platen performance, suitability for process integration, and reliable, sealing are calendar packs, sample packs, blisters with large efficient production of the highest quality. Attaining an output pockets, large blisters with stiffening ribs and all-aluminium of up to 1,300 blisters/minute, the B 1880 is the ideal solution blisters. The intermittent web index during filling is ideal for for the production of mass batches in 3-shift operation. filling systems with simultaneous product placement or other systems for products of irregular shape.

Open the catalog to page 1

Blister machine B 1880 with intermittent platen sealing The Blister machine B 1880 at a glance. Technical data: Output [1/min] Processable forming materials Al, PVC, PVC/PVDC, Sealing principle intermittent Processable lid materials Format area Space required Forming depth Machine width Machine height Reel diameter Lid material Machine length Forming material * optional format upgrade

Open the catalog to page 2

Blister machine B 1880 with intermittent platen sealing • Dual support for reels of forming material up to 1,000 mm in • Central touch screen operation with 3-D visualization diameter, also including buffer or splicer • Motorized forming material unwind prevents traction and tension • Three heating zones each for gentle heating of forming material • Perfect forming, e.g. thanks to pressure cushions and direct cooling of forming tools • GMP-compliant machine design for operation and cleaning in accordance with pharmaceutical specifications • Innovative door sliding and closing mechanism for...

Open the catalog to page 3All Uhlmann Pac-Systeme GmbH & Co. KG catalogs and technical brochures

-

VISIOSCAN

3 Pages

-

BEC 300

3 Pages

-

B 1880

3 Pages

-

VISIOREAD

3 Pages

-

L 180

3 Pages

-

BLU 400

3 Pages

-

BEC 500

3 Pages

-

BEC 200

3 Pages

-

BEC 700

3 Pages

-

IBC 150

3 Pages

-

CARTONERS

15 Pages

-

UPS 5

4 Pages

-

S 500

3 Pages

-

Intermittent motion cartoners

16 Pages

-

BLU 400

32 Pages

-

Blister machine UPS 5

20 Pages

-

Blister machine B 1240

7 Pages

-

Blister machine UPS 1030 ET

3 Pages

-

Blister machine B 1660

8 Pages

-

BLISTER MACHINE BLU 400

3 Pages

-

PartsManager

2 Pages

-

Rebuilds + Upgrades

2 Pages

-

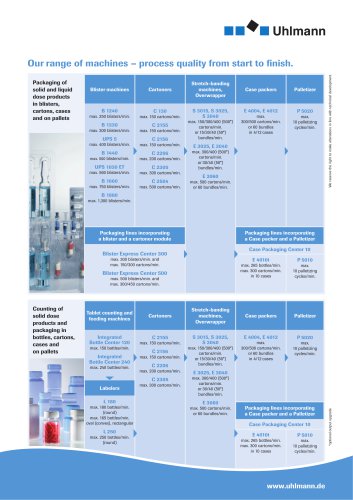

Range of Machines

1 Pages

-

Marking Machine KPM-200

5 Pages

-

Operating system Pac2Touch

2 Pages

-

Spare Part

2 Pages

-

Deblistering Device

2 Pages

-

Tablet Lift

2 Pages

-

Stand-alone Leaflet Folder

2 Pages

-

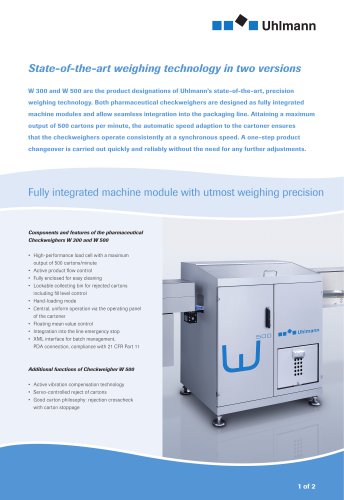

Checkweighers W300 and W 500

2 Pages

-

SimTap feeder

2 Pages

-

Integrated Bottle Center 120

3 Pages

-

Labeler L 250

3 Pages

-

TopTools

2 Pages

-

Track & Trace by Uhlmann

3 Pages

-

Integrated Bottle Center 240

2 Pages

-

Wraparound machine E 3060

3 Pages

-

Cartoner C 130

3 Pages

-

Blister Express Center 500

3 Pages

-

Blister Express Center 300

3 Pages

-

Cartoner C 2305, C 2504

3 Pages

-

Cartoner C 2156, C 2206

3 Pages

-

Cartoner C 2155

3 Pages

-

Blister machine B 1880 MTK

3 Pages

-

Palletizer P 5020

3 Pages

Archived catalogs

-

Blister machine B 1660 MTK

3 Pages

-

Blister machine B 1660 MTI

3 Pages

-

Blister machine UPS 1030

3 Pages

-

Case packer E 4040

3 Pages

-

Blister machine UPS 1040

3 Pages