Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Group: Uhlmann Group

Catalog excerpts

Blister machine B 1660 with intermittent platen sealing The universal high-performance machine with innovative process technology for maximum cost efficiency. Fast, efficient and user-friendly The Blister machine B 1660 is a universal high-performance The B 1660 with intermittent platen sealing is the ideal choice machine that processes up to 750 blisters/minute. Suitable for all for forming depths up to 12 mm. The principle of intermittent conceivable solid products, the B 1660 is available with inter- sealing with platen tools is particularly suitable mittent motion platen sealing and continuous motion rotary for the processing of special lid foils and paper or aluminum sealing. Users of the B 1660 benefit from a sophisticated tool laminates for so-called peel or peel-push blisters. Predestined quick-change system and a redesigned blister transfer. Addi- for platen sealing are calendar packs, sample packs, blisters tional attributes of the machine are straightforward operation with large pockets, large blisters with stiffening ribs and all- thanks to its state-of-the-art control concept and self-regulating aluminum blisters. The intermittent web index during filling is processes that ensure particularly gentle handling of the ideal for feeding systems with total discharge or other systems for exceptionally shaped products.

Open the catalog to page 1

Blister machine B 1660 with intermittent platen sealing The Blister machine B 1660 at a glance. Technical data: Output [1/min] Processable forming materials Al, PVC, PVC/PVDC, Sealing principle Format area Index x width Space required Forming depth Machine width Machine height Reel diameter Lid material Machine length Forming material * optional format upgrade

Open the catalog to page 2

Blister machine B 1660 with intermittent platen sealing • Dual reel support for reels up to 1,000 mm in diameter, also • IPC (in-process control) discharge during production run with buffer for up to 3 hours non-stop production • Powered forming material unwind prevents traction and tension, lateral web control, pinhole detection for damage over 10 μm • Three heating zones for gradual heating of the forming material to the ideal temperature • Production data acquisition system for fast process analysis • Straightforward user guidance with state-of-the-art TouchControl system with 3-D...

Open the catalog to page 3All Uhlmann Pac-Systeme GmbH & Co. KG catalogs and technical brochures

-

VISIOSCAN

3 Pages

-

BEC 300

3 Pages

-

B 1880

3 Pages

-

VISIOREAD

3 Pages

-

L 180

3 Pages

-

BLU 400

3 Pages

-

BEC 500

3 Pages

-

BEC 200

3 Pages

-

BEC 700

3 Pages

-

IBC 150

3 Pages

-

CARTONERS

15 Pages

-

UPS 5

4 Pages

-

S 500

3 Pages

-

Intermittent motion cartoners

16 Pages

-

BLU 400

32 Pages

-

Blister machine UPS 5

20 Pages

-

Blister machine B 1240

7 Pages

-

Blister machine UPS 1030 ET

3 Pages

-

Blister machine B 1660

8 Pages

-

BLISTER MACHINE BLU 400

3 Pages

-

PartsManager

2 Pages

-

Rebuilds + Upgrades

2 Pages

-

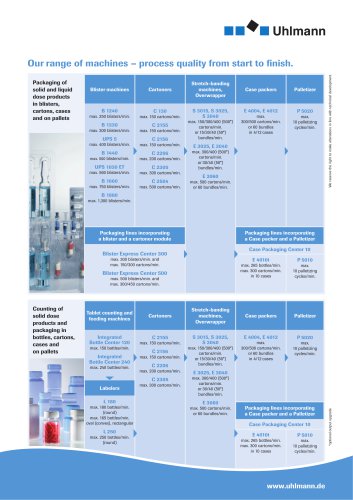

Range of Machines

1 Pages

-

Marking Machine KPM-200

5 Pages

-

Operating system Pac2Touch

2 Pages

-

Spare Part

2 Pages

-

Deblistering Device

2 Pages

-

Tablet Lift

2 Pages

-

Stand-alone Leaflet Folder

2 Pages

-

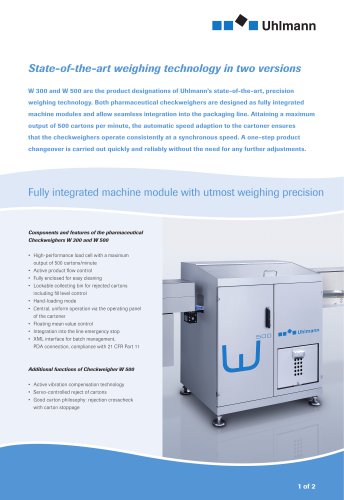

Checkweighers W300 and W 500

2 Pages

-

SimTap feeder

2 Pages

-

Integrated Bottle Center 120

3 Pages

-

Labeler L 250

3 Pages

-

TopTools

2 Pages

-

Track & Trace by Uhlmann

3 Pages

-

Integrated Bottle Center 240

2 Pages

-

Wraparound machine E 3060

3 Pages

-

Cartoner C 130

3 Pages

-

Blister Express Center 500

3 Pages

-

Blister Express Center 300

3 Pages

-

Cartoner C 2305, C 2504

3 Pages

-

Cartoner C 2156, C 2206

3 Pages

-

Cartoner C 2155

3 Pages

-

Blister machine B 1880 MTK

3 Pages

-

Blister machine B 1880 MTI

3 Pages

-

Palletizer P 5020

3 Pages

Archived catalogs

-

Blister machine B 1660 MTK

3 Pages

-

Blister machine UPS 1030

3 Pages

-

Case packer E 4040

3 Pages

-

Blister machine UPS 1040

3 Pages