Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Group: Uhlmann Group

Catalog excerpts

Blister machine UPS 5 Focus on product diversity

Open the catalog to page 1

The fast and efficient translation of customer requirements into world-class packaging machines and solutions is one of Uhlmann’s guiding principles. A central part of this process is evolution, the optimization of machines and their consistent development into a new class of machines. This is the case with the Blister machine UPS 5. The success story of this machine for diverse applications in pharmaceutical production began in 1977 with the UPS 1. At every subsequent development stage, Uhlmann engineers supplemented proven features with innovative components and state-of-the-art...

Open the catalog to page 3

The philosophy behind the Blister machine UPS 5 Building on the success of the UPS 4 and its outstanding flexibility in blister packaging technology, the UPS 5 expands that potential by combining established and proven features with even greater benefits in the context of state-of-the-art technology, ease of operation, maintenance, and flexibility.

Open the catalog to page 4

The GMP-compliant Blister machine UPS 5 sets The large format area and a forming depth of up standards in flexible, productive pharmaceutical to 40 mm enable the UPS 5 to package liquid dose packaging processes. The modular frame allows products such as ampoules, cartridges, vials and variable configurations and machine upgrades at all syringes in addition to solid dose products. The times. Each station forms an individual unit and is format area of 226 x 284 mm – extendable to mounted separately on the machine frame. Enclosure 272 x 284 mm – is particularly suitable for large- of all the...

Open the catalog to page 5

The technology of the Blister machine UPS 5 The UPS 5 is ideal for the productive packaging of solid and liquid dose products. Its modular concept and ease of operation meet the current demand for customized, flexible processes. Forming material reel support: diverse options Heating station: automatic heat control The UPS 5 can be fitted with forming material reels Three adjustable heating zones on the heating plates up to 800 mm in diameter, which allow extended ensure an optimum forming process and extend operation. Changing of the reel is made easier by the heating area over three...

Open the catalog to page 6

Forming station: universal, efficient The universal forming station processes all common forming depths of 10 mm to 40 mm, which makes it types of forming material with consistent reliability. the ideal machine for the packaging of liquid dose Features include a four-column lifter unit that ensures products, tropical blisters, and Al/Al blisters. Plug even distribution of the station closing pressure of assist dies are used for larger forming depths and up to 80 kN. As the forming station, like most of the certain wall thickness distributions, e.g. in the case UPS 5 stations, is driven by a...

Open the catalog to page 7

The technology of the Blister machine UPS 5 Feeders: efficient and gentle product handling A wide selection of feeders can be used with the upstream machines, e.g. an ampoule filling machine, UPS 5 – both for liquid and solid dose products. direct, seamless linking is guaranteed. SyPro and LiPro are the feeding systems for liquid dose products. SyPro – short for Syringe Product – Feeders are available for the handling of every shape, operates with a swivel-arm robot for the gentle size and type of solid dose products. SimTap feeders feeding of fragile glass or plastic syringes. LiPro – with...

Open the catalog to page 8

Lid material reel support and unwind: minimum tolerances ideal for multiphase blisters, and the linear feeder The lid material reel can be positioned at the front handles products of complex shape, ones with or on the rear side of the UPS 5. The lid material noticeable differences in tolerance range, and elongation function ensures high-precision print products susceptible to shingling. mark control with tolerances of just ± 0.2 mm. The print mark registration for paper lid materials is No matter whether solid or liquid dose products, driven by a servo-regulated index. the fill section of...

Open the catalog to page 9

The technology of the Blister machine UPS 5 Perforating: utmost precision Punching: accurate and quiet The perforating station operates with utmost The high-precision tools in the cam controlled precision. Its four-column technology guarantees punching station allow very accurate blister even pressure distribution for optimum results. punching. When processing very long material Furthermore, the individually fixed perforating lengths, an optional, floating, laser-controlled punch knives are easy to replace. Compared to the UPS 4 can be used to compensate shrinkage. The new predecessor...

Open the catalog to page 10

Discharge conveyor: individually adjustable Only perfect blisters are accepted by the pick-and-place vacuum function and transferred to the cartoner. The speed of the conveyor can be adjusted independent of the main drive of the blister machine. This allows the integration of a downstream machine tailored to requirements. Operation, format changeover and cleaning The central touchscreen control system with 3-D visualization simplifies operation. Tool-free format changeovers are carried out quickly as they involve few format parts. A special format parts trolley facilitates transportation...

Open the catalog to page 11

Design^! Operation Technology highlights of the Blister machine UPS 5 • Servo-regulated indexes and blister transfer • Modular, enclosed stations • Easy-to-exchange heating plates • Universal forming station for all types of forming materials • Large forming depth and suitable for large-sized blisters • Innovative and intelligent technical solutions for sealing, embossing, perforating and punching • Individually adjustable speed at discharge conveyor - adaptable to the downstream machine O Self-explanatory operation via touchscreen with 3-D visualization O Fast and easy,...

Open the catalog to page 12

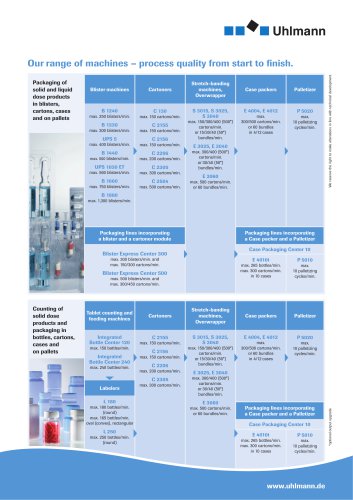

Guaranteed process quality from a single source. Customized solutions that meet every need from the concept to the fully integrated line. Example of a Customized Packaging System: a synchronized packaging line for the production of multiphase blisters with downstream secondary packaging. All process steps throughout the line are optimally coordinated and accurately monitored – from the blister machine and cartoner to the packed cases on pallets. Uhlmann specialists develop and realize customized whole. This includes design and feasibility studies, packaging solutions from the company’s...

Open the catalog to page 14All Uhlmann Pac-Systeme GmbH & Co. KG catalogs and technical brochures

-

VISIOSCAN

3 Pages

-

BEC 300

3 Pages

-

B 1880

3 Pages

-

VISIOREAD

3 Pages

-

L 180

3 Pages

-

BLU 400

3 Pages

-

BEC 500

3 Pages

-

BEC 200

3 Pages

-

BEC 700

3 Pages

-

IBC 150

3 Pages

-

CARTONERS

15 Pages

-

UPS 5

4 Pages

-

S 500

3 Pages

-

Intermittent motion cartoners

16 Pages

-

BLU 400

32 Pages

-

Blister machine B 1240

7 Pages

-

Blister machine UPS 1030 ET

3 Pages

-

Blister machine B 1660

8 Pages

-

BLISTER MACHINE BLU 400

3 Pages

-

PartsManager

2 Pages

-

Rebuilds + Upgrades

2 Pages

-

Range of Machines

1 Pages

-

Marking Machine KPM-200

5 Pages

-

Operating system Pac2Touch

2 Pages

-

Spare Part

2 Pages

-

Deblistering Device

2 Pages

-

Tablet Lift

2 Pages

-

Stand-alone Leaflet Folder

2 Pages

-

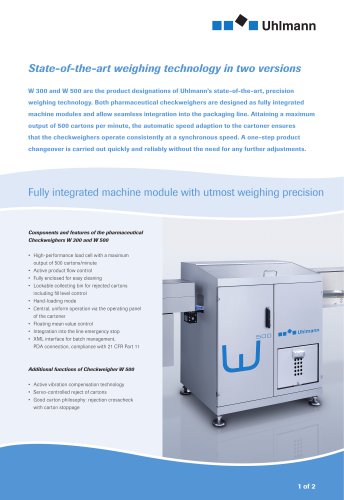

Checkweighers W300 and W 500

2 Pages

-

SimTap feeder

2 Pages

-

Integrated Bottle Center 120

3 Pages

-

Labeler L 250

3 Pages

-

TopTools

2 Pages

-

Track & Trace by Uhlmann

3 Pages

-

Integrated Bottle Center 240

2 Pages

-

Wraparound machine E 3060

3 Pages

-

Cartoner C 130

3 Pages

-

Blister Express Center 500

3 Pages

-

Blister Express Center 300

3 Pages

-

Cartoner C 2305, C 2504

3 Pages

-

Cartoner C 2156, C 2206

3 Pages

-

Cartoner C 2155

3 Pages

-

Blister machine B 1880 MTK

3 Pages

-

Blister machine B 1880 MTI

3 Pages

-

Palletizer P 5020

3 Pages

Archived catalogs

-

Blister machine B 1660 MTK

3 Pages

-

Blister machine B 1660 MTI

3 Pages

-

Blister machine UPS 1030

3 Pages

-

Case packer E 4040

3 Pages

-

Blister machine UPS 1040

3 Pages