Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Group: Uhlmann Group

Catalog excerpts

BLISTER MACHINE BLU 400 UNSURPASSED FLEXIBILITY. EXCEPTIONALLY GENTLE PRODUCT HANDLING. REMARKABLE EFFICIENCY. Ampoules, syringes, vials, bottles, cartridges, or pens: the BLU 400 is tailored to the needs of the pharmaceutical market when it comes to the packaging of liquid dose products. Based on a detailed and well-conceived concept, it convincingly ensures safe and gentle product handling throughout the entire packaging process. With unrivaled safety functions that protect even the most susceptible products at all stages: for instance, against heat, breakage, or mix-ups. And that combined with utmost flexibility and eciency – at an output of up to 400 blisters per minute. The principle of the BLU 400 is an extremely flexible modular design adaptable in practice to virtually every scenario. It oers a wide range of options to enable you to respond swiftly at any time to all product requirements. In addition, the BLU 400 is extremely economic and is prudent in all respects when it comes to your resources. It minimizes the rejection of faulty packages and forming material consumption; operation and retooling involve limited time and manpower. UNCOMPROMISINGLY GEARED TO LIQUID DOSE PRODUCTS.

Open the catalog to page 1

TECHNICAL DATA OF BLU 400 Processable forming materials Sealing principle Format area [V x B] Material thickness Reel diameter forming material max. 800 mm lid material max. 400 mm Forming depth Machine height (without printer) Machine top Opened cover Machine width (doors open) Machine length (without lid material) 1. Forming material carrier 2. Forming material unwinding 3. Cutting and splicing table for forming material 4. Forming material splice detection 5. Web centering 6. Heating station 7. Forming station 8. Index after forming 9. Feeder 10. Press-in station 11. Safety flap 12. Fill...

Open the catalog to page 2

BLISTER MACHINE BLU 400 Features High flexibility • Forming material unwinding with cutting and splicing table for reels with a max. outer diameter of 800 mm integrated into machine or mounted on the machine’s narrow side (option). • Fill section is highly variable and can be replaced at the customer’s site. • Production of sealed blisters (option): lid material unwinding with cutting and splicing table for reels with a max. outer diameter of 400 mm integrated into machine or mounted on the machine‘s rear side (option). • Manual product reloading at low speed (option). LiPro feeder Press-in...

Open the catalog to page 3All Uhlmann Pac-Systeme GmbH & Co. KG catalogs and technical brochures

-

VISIOSCAN

3 Pages

-

BEC 300

3 Pages

-

B 1880

3 Pages

-

VISIOREAD

3 Pages

-

L 180

3 Pages

-

BLU 400

3 Pages

-

BEC 500

3 Pages

-

BEC 200

3 Pages

-

BEC 700

3 Pages

-

IBC 150

3 Pages

-

CARTONERS

15 Pages

-

UPS 5

4 Pages

-

S 500

3 Pages

-

Intermittent motion cartoners

16 Pages

-

BLU 400

32 Pages

-

Blister machine UPS 5

20 Pages

-

Blister machine B 1240

7 Pages

-

Blister machine UPS 1030 ET

3 Pages

-

Blister machine B 1660

8 Pages

-

PartsManager

2 Pages

-

Rebuilds + Upgrades

2 Pages

-

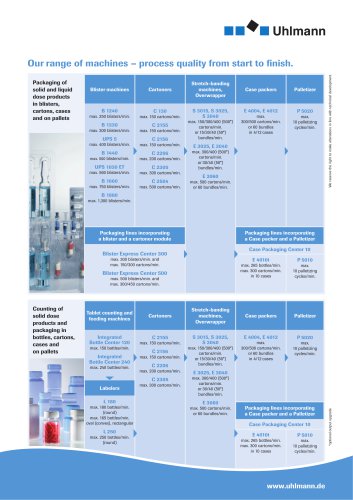

Range of Machines

1 Pages

-

Marking Machine KPM-200

5 Pages

-

Operating system Pac2Touch

2 Pages

-

Spare Part

2 Pages

-

Deblistering Device

2 Pages

-

Tablet Lift

2 Pages

-

Stand-alone Leaflet Folder

2 Pages

-

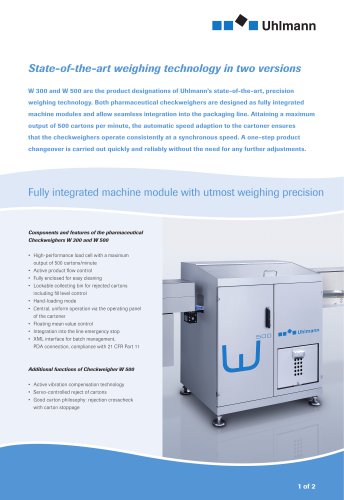

Checkweighers W300 and W 500

2 Pages

-

SimTap feeder

2 Pages

-

Integrated Bottle Center 120

3 Pages

-

Labeler L 250

3 Pages

-

TopTools

2 Pages

-

Track & Trace by Uhlmann

3 Pages

-

Integrated Bottle Center 240

2 Pages

-

Wraparound machine E 3060

3 Pages

-

Cartoner C 130

3 Pages

-

Blister Express Center 500

3 Pages

-

Blister Express Center 300

3 Pages

-

Cartoner C 2305, C 2504

3 Pages

-

Cartoner C 2156, C 2206

3 Pages

-

Cartoner C 2155

3 Pages

-

Blister machine B 1880 MTK

3 Pages

-

Blister machine B 1880 MTI

3 Pages

-

Palletizer P 5020

3 Pages

Archived catalogs

-

Blister machine B 1660 MTK

3 Pages

-

Blister machine B 1660 MTI

3 Pages

-

Blister machine UPS 1030

3 Pages

-

Case packer E 4040

3 Pages

-

Blister machine UPS 1040

3 Pages