Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Website:

Uhlmann Pac-Systeme GmbH & Co. KG

Group: Uhlmann Group

Catalog excerpts

Blister machine B 1660 with continuous rotary sealing The universal high-performance machine with innovative process technology for maximum cost efficiency. Fast, efficient and user-friendly The Blister machine B 1660 is a universal high-performance The B 1660 with continuous filling and rotary sealing is the ideal machine that processes up to 750 blisters/minute. Suitable for super high-speed machine for standard blisters containing all conceivable solid products, the B 1660 is available with symmetrical products, such as round tablets and capsules, which intermittent motion platen sealing and continuous motion rotary can be handled by a vibratory feeder and fill channels. This sealing. Users of the B 1660 benefit from a sophisticated tool method of packaging with continuous feeding and rotary quick-change system and a redesigned blister transfer. Additional sealing ensures the gentlest handling and most fluent attributes of the machine are straightforward operation thanks to production process. its state-of-the-art control concept and self-regulating processes that ensure particularly gentle handling of the products.

Open the catalog to page 1

Blister machine B 1660 with continuous rotary sealing The Blister machine B 1660 at a glance. Technical data: Output [1/min] Processable forming materials Al, PVC, PVC/PVDC, Processable lid materials Sealing principle Format area Index x width Space required Forming depth Machine width Machine height Reel diameter Lid material Machine length Forming material

Open the catalog to page 2

Blister machine B 1660 with continuous rotary sealing • Dual reel support for reels up to 1,000 mm in diameter, also • IPC (in-process control) discharge during production run with buffer for up to 3 hours non-stop production • Powered forming material unwind prevents traction and tension, lateral web control, pinhole detection for damage over 10 μm • Three heating zones for gradual heating of the forming material to the ideal temperature • Production data acquisition system for fast process analysis • Straightforward user guidance with state-of-the-art TouchControl system with 3-D...

Open the catalog to page 3All Uhlmann Pac-Systeme GmbH & Co. KG catalogs and technical brochures

-

VISIOSCAN

3 Pages

-

BEC 300

3 Pages

-

B 1880

3 Pages

-

VISIOREAD

3 Pages

-

L 180

3 Pages

-

BLU 400

3 Pages

-

BEC 500

3 Pages

-

BEC 200

3 Pages

-

BEC 700

3 Pages

-

IBC 150

3 Pages

-

CARTONERS

15 Pages

-

UPS 5

4 Pages

-

S 500

3 Pages

-

Intermittent motion cartoners

16 Pages

-

BLU 400

32 Pages

-

Blister machine UPS 5

20 Pages

-

Blister machine B 1240

7 Pages

-

Blister machine UPS 1030 ET

3 Pages

-

Blister machine B 1660

8 Pages

-

BLISTER MACHINE BLU 400

3 Pages

-

PartsManager

2 Pages

-

Rebuilds + Upgrades

2 Pages

-

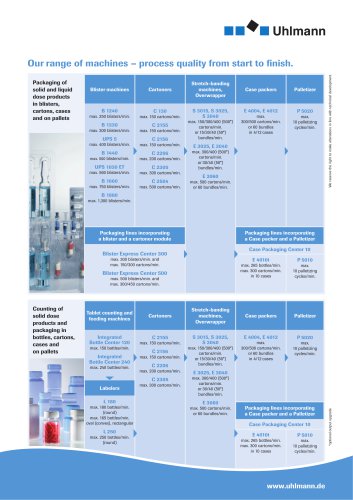

Range of Machines

1 Pages

-

Marking Machine KPM-200

5 Pages

-

Operating system Pac2Touch

2 Pages

-

Spare Part

2 Pages

-

Deblistering Device

2 Pages

-

Tablet Lift

2 Pages

-

Stand-alone Leaflet Folder

2 Pages

-

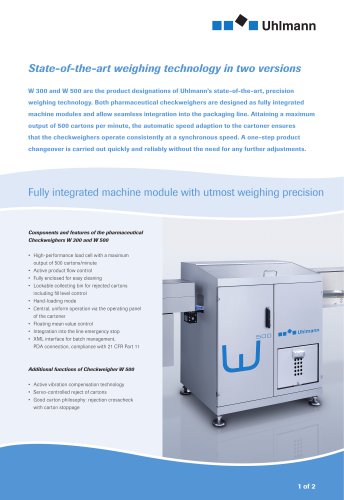

Checkweighers W300 and W 500

2 Pages

-

SimTap feeder

2 Pages

-

Integrated Bottle Center 120

3 Pages

-

Labeler L 250

3 Pages

-

TopTools

2 Pages

-

Track & Trace by Uhlmann

3 Pages

-

Integrated Bottle Center 240

2 Pages

-

Wraparound machine E 3060

3 Pages

-

Cartoner C 130

3 Pages

-

Blister Express Center 500

3 Pages

-

Blister Express Center 300

3 Pages

-

Cartoner C 2305, C 2504

3 Pages

-

Cartoner C 2156, C 2206

3 Pages

-

Cartoner C 2155

3 Pages

-

Blister machine B 1880 MTK

3 Pages

-

Blister machine B 1880 MTI

3 Pages

-

Palletizer P 5020

3 Pages

Archived catalogs

-

Blister machine B 1660 MTI

3 Pages

-

Blister machine UPS 1030

3 Pages

-

Case packer E 4040

3 Pages

-

Blister machine UPS 1040

3 Pages