Website:

Tyrolit - Schleifmittelwerke Swarovski AG & Co K.G

Website:

Tyrolit - Schleifmittelwerke Swarovski AG & Co K.G

Group: SWAROVSKI Group

Catalog excerpts

Sandflex Flap Discs are manufactured by Grinding Techniques in South Africa. Competitively priced product which ensures value for money. The lighter pressures required for operation result in increased machine life and productivity. Cool and soft cut, with less loading. Reinforced fibre back support eliminates the need for expensive back-up pads, as Flap Discs bolt directly onto the grinder. This also enables the product to be used for tight corner grinding and sanding. The fibreglass support is also contamination free. Constant rate of stock removal and consistent finish during the entire life of the abrasive flaps. FLAP DISCS FOR PORTABLE GRINDERS Flap Disc bolts directly onto the grinder. No back-up pad required. Reinforced fibreglass back support. Contamination free. Multilayer abrasive grinding flap. Sandflex Flap Discs are designed for use on portable grinders and sanders, and are increasingly popular as an alternative to abrasive fibre discs. They complement the use of depressed centre grinding wheels, and are the preferred option on light gauge sheet metal or stainless steel where finish is important Fast stock removal due to the 80m/sec. operating speed. This also makes the product suitable for rough grinding. In many cases the number of working processes are reduced - both rough and intermediate grinding can be done with the same Flap Disc. Flap Discs can last 20 to 30 times longer than Fibre Discs, but only cost between 10 to 15 times as much. You save in material costs, plus downtime whilst Fibre Discs are being changed. Grinding Techniques dedication to ongoing technological innovation, and the use of only the finest specially engineered raw materials in production, ensures that our products are manufactured to the highest international standards. Our quality products, customer service and competitive pricing ensures complete customer satisfaction. 28 Van Eck Street • Chamdor • Krugersdorp • South Africa PO Box 51 • Krugersdorp 1740 • South Africa Tel +27 11 271 6400 • Fax +27 11 271 6464 E-Mail: sandflex@grindtech.com Website: www.grindtech.com

Open the catalog to page 1

INDUSTRIAL RANGE ABRASIVE TYPE Aluminium Oxide abrasive is preferred for DIY use as it is the most cost effective product for most DIY applications. 27 - Std • • • 27 - Std • • • 27 - Std • • • • Normal standard stock • Ex manufacture Grit 24 and 40: for aluminium and other soft non-ferrous metals, wood and plastics Grit 40 and 60: for alloyed and low-alloyed steels Grit 60 and 80: for high alloyed, stainless, heat treatable steels, and high tensile non-ferrous metals Grit 120: for a fine finish of metal surfaces As starting points, we recommend: Aluminium Oxide Abrasive (A) This new disc...

Open the catalog to page 2All Tyrolit - Schleifmittelwerke Swarovski AG & Co K.G catalogs and technical brochures

-

Tyrolit Factsheet

6 Pages

-

FOCUR SA

4 Pages

-

MIRA ULTRA SF

2 Pages

-

STARTEC XP-P

2 Pages

-

DIAMANT

8 Pages

-

COOL CUT

18 Pages

-

GENIS CF

2 Pages

-

GENIS 2

2 Pages

-

andorflex

4 Pages

-

Diamond Saw

2 Pages

-

ABRASIVE PRODUCTS CATALOGUE

87 Pages

-

saw

4 Pages

-

Product Innovations 2015

20 Pages

-

DIAMOND WET core drills

8 Pages

-

Construction trade

148 Pages

-

Tyrolit Flap Disc Program

12 Pages

-

Skytec pcd-Basic+

12 Pages

-

GENIS

6 Pages

-

STARTEC CNC Flyer

22 Pages

-

COOL-CUT Flyer

16 Pages

-

Glass

6 Pages

-

Ceramics

6 Pages

-

Stone

6 Pages

-

Coated

71 Pages

-

INDUSTRIAL SUPPLY

239 Pages

-

Construction Professional

114 Pages

-

Tile saw TTE250

2 Pages

-

Ring Saw Blades

6 Pages

-

Core drilling system DRS160

2 Pages

Archived catalogs

-

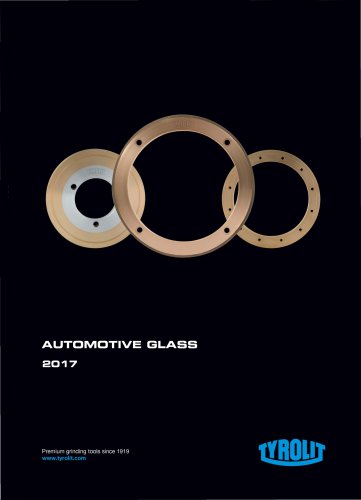

Automative class 2017

24 Pages

-

CONSTRUCTION RELATED TRADE

125 Pages