Catalog excerpts

Tuthill Plastic Group AtTuthill Plastics Group, Goal #1 is exceptional customer service. Tuthill Plastics Group Providing Engineering Assistance and Product Development Other injection molders said they couldn’t make this wire sealant used in nuclear power plants. Our engineers found the solution. Everyone involved in manufacturing today— engineering, purchasing, and quality assurance—must be constantly aware of their responsibilities. Purchasing wants lower costs. Engineering wants better performance and ease of manufacturing. Quality Assurance wants consistent high quality parts. We expect this from our vendors and you have every right to expect this from us. We can help you achieve these goals with our experience. Don’t put your job on the line—call us! Previously machined from steel, this sealant has 121 precise holes to guide control wires. Tuthill engineers designed a mold to produce a highly precise polysulfone part at dramatic savings in material, cost, and production time. No sinks, No voids, No stress! MATERIAL SAVINGS – 90%CYCLE TIME REDUCTION – FROM 5 HOURS TO 1 MINUTE Insert Molding All of our resources are utilized to ensure customer satisfaction and create exceptional value using lean manufacturing principles. We believe our success comes from the strong partnerships we develop with our customers. Metal to Plastics Conversion Retainer Ring Tuthill Plastics Group started as a molder of stainless steel and brass inserts. It has expanded to nylon mesh, magnets, and a variety of metal inserts. We have successfully converted metal parts to plastic parts, saving our customers money on costly secondary machining operations and increasing their production. In the above example we have done this and produced a housing using a clear resin. .580” diameter ring with .020” wall and v-groove that breaks at a predetermined PSI. Automated assembly impact on customer product - 60% increase in yield & throughput. Two Stage Molding Polypropylene part insert molded with Santoprene. Shore A45 material provides an integrated flexible housing. Rotor Rotor moving and stationary: Overmolding of a spider gear with .080” to .070” wall thickness in peek material with less than .009” deflection. “ Conscious Company” A We are a full service custom injection molding company. Our expertise ranges from critical tolerance engineering of complex components to standard consumer commodity products. Some of the market segments that Tuthill Plastics Group currently supplies include: metering devices, pumps, defense, automotive, consumer products, and industrial electronics. Tuthill Plastics Group is in the process of training all of our employees to be radical leaders, encouraging them to be courageous and powerful, creative and innovative pioneering thinkers. Radical leaders are individuals who live from a true sense of vision and take a stand for seeing that vision fulfilled. They operate from their own personal power, take 100% responsibility for their impact on the world and are deeply committed to living in integrity—with themselves and those around them. 2050 Sunnydale Boulevard Clearwater, Florida USA 33765 Tel 727-446-8593 Fax 727-446-8595 2050 Sunnydale Boulevard Clearwater, Florida USA 33765 Tel 727-446-8593 Fax 727-446-8595 LeadingToday’sTechnology in Injection Molding Y Partner in: Product Development • Material Selection • Produ

Open the catalog to page 1

Tuthill Plastic Group AtTuthill Plastics Group, Goal #1 is exceptional customer service. Tuthill Plastics Group Providing Engineering Assistance and Product Development Other injection molders said they couldn’t make this wire sealant used in nuclear power plants. Our engineers found the solution. Everyone involved in manufacturing today— engineering, purchasing, and quality assurance—must be constantly aware of their responsibilities. Purchasing wants lower costs. Engineering wants better performance and ease of manufacturing. Quality Assurance wants consistent high quality parts. We...

Open the catalog to page 2

Plastic Part Design Prototype Molds • We can accept any Auto CAD, Pro/ENGINEER, or SolidWorks format. • 3D Printing Systems can quickly create a physical acrylic resin model from an STL file to verify the design concept and confirm its conformance to fit, form, and function. All of these are verified before ever cutting steel to build the mold, saving time and money. Tuthill Plastics Group started its journey on the road of Lean Manufacturing in 1999—developing and implementing the Tuthill Business Systems. This is based on the Toyota Business System of Continuous Improvement focusing...

Open the catalog to page 3

Plastic Part Design Prototype Molds • We can accept any Auto CAD, Pro/ENGINEER, or SolidWorks format. • 3D Printing Systems can quickly create a physical acrylic resin model from an STL file to verify the design concept and confirm its conformance to fit, form, and function. All of these are verified before ever cutting steel to build the mold, saving time and money. Tuthill Plastics Group started its journey on the road of Lean Manufacturing in 1999—developing and implementing the Tuthill Business Systems. This is based on the Toyota Business System of Continuous Improvement focusing...

Open the catalog to page 4

Plastic Part Design Prototype Molds • We can accept any Auto CAD, Pro/ENGINEER, or SolidWorks format. • 3D Printing Systems can quickly create a physical acrylic resin model from an STL file to verify the design concept and confirm its conformance to fit, form, and function. All of these are verified before ever cutting steel to build the mold, saving time and money. Tuthill Plastics Group started its journey on the road of Lean Manufacturing in 1999—developing and implementing the Tuthill Business Systems. This is based on the Toyota Business System of Continuous Improvement focusing...

Open the catalog to page 5

Tuthill Plastic Group AtTuthill Plastics Group, Goal #1 is exceptional customer service. Tuthill Plastics Group Providing Engineering Assistance and Product Development Other injection molders said they couldn’t make this wire sealant used in nuclear power plants. Our engineers found the solution. Everyone involved in manufacturing today— engineering, purchasing, and quality assurance—must be constantly aware of their responsibilities. Purchasing wants lower costs. Engineering wants better performance and ease of manufacturing. Quality Assurance wants consistent high quality parts. We...

Open the catalog to page 6All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

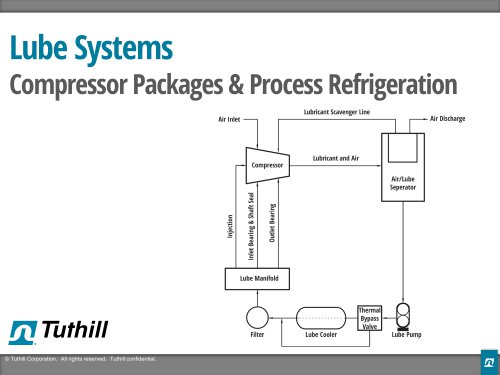

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

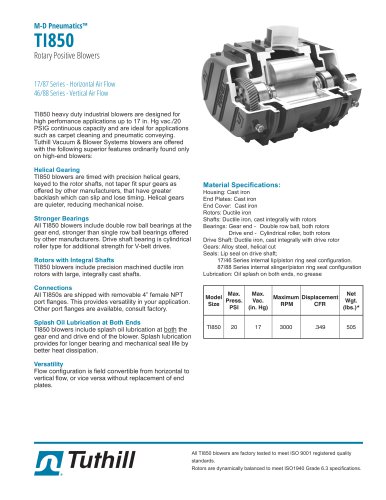

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

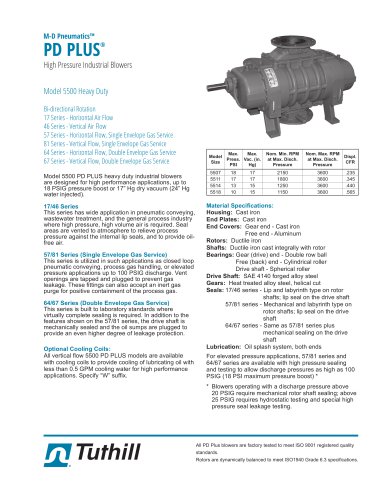

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

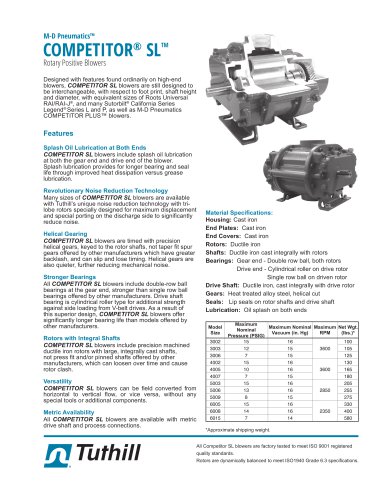

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

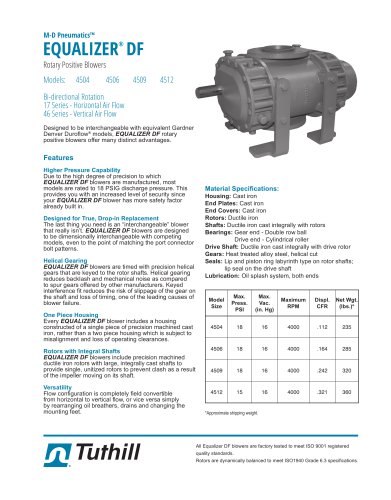

Equalizer DF TH-046

2 Pages

-

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages