Catalog excerpts

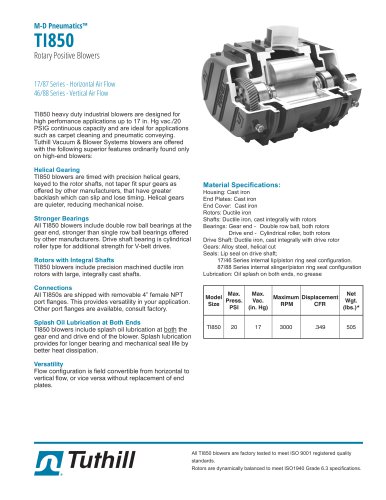

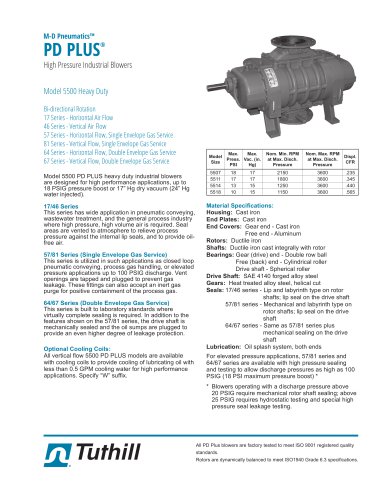

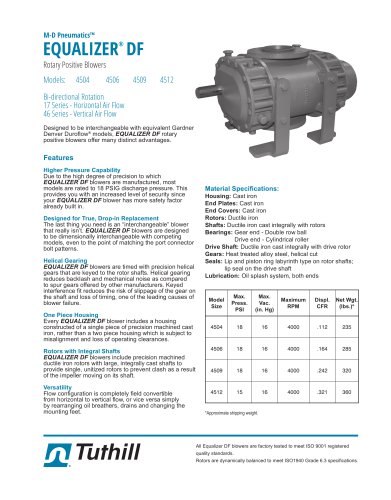

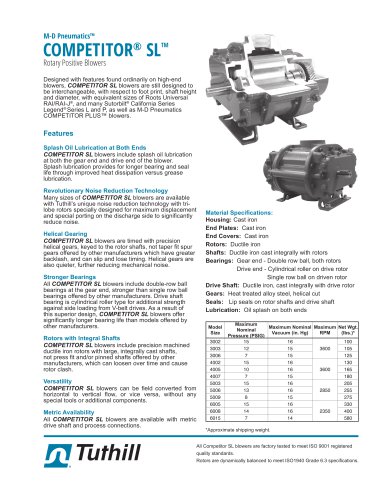

High Pressure Industrial Blowers Model 1200 Heavy Duty Bi-directional Rotation 19 Series - Horizontal Air Flow 86 Series - Vertical Air Flow 55 Series - Horizontal Flow, Single Envelope Gas Service 82 Series - Vertical Flow, Single Envelope Gas Service 66 Series - Horizontal Flow, Double Envelope Gas Service 69 Series - Vertical Flow, Double Envelope Gas Service Model 1200 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 15 PSIG pressure boost or 15” Hg dry vacuum (24” Hg water injected). 19/86 Series This series has wide application in pneumatic conveying, wastewater treatment and the general process industry where high pressure, high volume air is required. Seal areas are vented to atmosphere to relieve process pressure against the internal lip seals, and to provide oilfree air. 55/82 Series (Single Envelope Gas Service) This series is utilized in such applications as closed loop pneumatic conveying, process gas handling, or elevated pressure applications up to 100 PSIG discharge. Vent openings are tapped and plugged to prevent gas leakage. These fittings can also accept an inert gas purge for positive containment of the process gas. 66/69 Series (Double Envelope Gas Service) This series is built to laboratory standards where virtually complete sealing is required. In addition to the features shown on the 55/82 series, the drive shaft is mechanically sealed and the oil sumps are plugged to provide an even higher degree of leakage protection. Material Specifications: Housing: Cast iron End Plates: Cast iron End Covers: Cast iron Rotors: Ductile iron Shafts: Ductile iron cast integrally with rotor Bearings: Rotor shafts - Double row ball Drive shaft - Spherical roller Drive Shaft: SAE 4140 forged alloy steel Gears: Heat treated alloy steel, helical cut Seals: 19/86 - Lip and labyrinth type on the rotor shafts; lip seal on the drive shaft 55/82 - Mechanical and labyrinth type on the rotor shafts; lip seal on the drive shaft 66/69 - Same as 55/82 plus mechanical sealing on the drive shaft Lubrication: Bearings are lubricated by an integral pressure system including filter and oil to water heat exchanger; gears are splash lubricated. For elevated pressure applications, 55/82 series and 66/69 series are available with high pressure sealing and testing to allow discharge pressures as high as 100 PSIG (up to a 15 PSI maximum pressure boost)* * Blowers operating with a discharge pressure above 20 PSIG require mechanical rotor shaft sealing; above 25 PSIG requires hydrostatic testing and special high pressure seal leakage testing. Model Size All PD Plus blowers are factory tested to meet ISO 9001 registered quality standards. Rotors are dynamically balanced to meet ISO1940 Grade 6.3 specifications.

Open the catalog to page 1

Performance Tables In conjunction with our program of continuous testing and design upgrading, all specifications are subject to change without notice. All data are approximate. Request a quotation for your specific application. Pressure (14.70 PSIA and 70° F Inlet) BLOWER MODEL Shaded areas indicate operation requiring soft starting of motor. Direct or jackshaft drive is required above 250 HP. Applications in shaded areas must be factory approved. Series 19/55 (Horizontal Flow) C OIL FILL PLUG (1) EA. END PLATE Series 82/86 (Vertical Flow) INSTRUMENTATION CONNECTION 1/2 NPT (2) EA. PORT...

Open the catalog to page 2All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

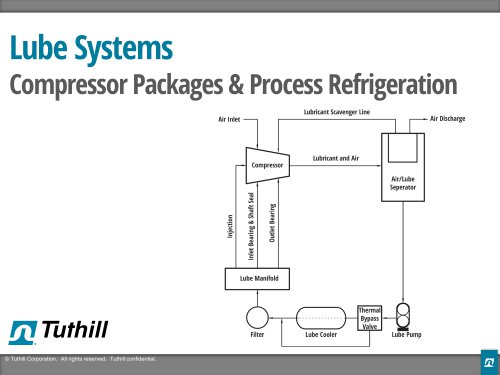

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

Equalizer DF TH-046

2 Pages

-

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages