Catalog excerpts

Installation and Service Instructions HD Series Pumps Excellence at work. Excellence in life.

Open the catalog to page 1

Table of Contents Introduction General Parts List for Model 600 Pumps General Description 600 Pumps (Models Starting w/ O5 & Mech. Seals) Pumping Principle General Parts List for Model 600 Pumps Disassembly & Reassembly for Model 600 Pumps HD Process Pump Numbering System Fluid Chamber Check Points Temperature Limits of HD Process Pump Materials Reassemble In Accordance With Minor Reassembly Major Disassembly Instructions Packing Adjustment Lubrication Requirements Chamber Clearances Lubrication Instructions for Tuthill Process Pumps Torque For Shaft Locknuts 70A, 120A, and 330 Pumps...

Open the catalog to page 2

Introduction The HD Series pumps have been certified to the requirements of the ATEX Directive 94/9/EC for use in Category II, Group 2 G applications. Read this manual before operating or working on the HD Series pumps. If additional information is required to facilitate operation or maintenance, contact the authorized Tuthill distributor shown at the back of this service manual. HD Series pumps have been designed and manufactured to provide years of service under normal operating conditions. Illustrations used in this manual are for reference purposes only. Consult the factory or an...

Open the catalog to page 3

Stainless Steel Version 1.8 Port Size (Internal NPT) 1-1/2” Top 1-1/2” Front 2” Top 2” Front 3” Top 3” Front 3” Top 2” Front 4” Top 3” Front 5” Top 4” Front 6” Right 6” Left Same As Above Same As Above Same As Above Same As Above Same As Above Same As Above Sa

Open the catalog to page 4

HD Process Pump Numbering System 1 O5 – INDUSTRIAL DUTY (ID) Only Models with ** O2-STANDARD DUTY (SD) Ductile Iron Only O4-STANDARD DUTY (SD) Stainless Steel Only 05 – Model 30 01 – Model 5A 14 – Model 2A 02 – Model 10 16 – Model 70A** 03 – Model 16 29 – Model 3A 05 – Model 25A 31 – Model 120A** 14 – Model 65 75 – Model 330** 26 – Model 125A 91 – Model 600** DIGITS 5 & 6 04 – 316 Stainless Steel (O1, O4 & O5 Models) 09 – Ductile Iron (O1, O2 & O5 Models) DIGIT 7 0 – Internal NPT (Std. on ID models) 1 – External NPT (Standard on SD models) DIGIT 8 0 – No Relief Valve 1 – Relief Valve...

Open the catalog to page 5

150 °F PTFE-Glass Filled Gaskets Viton Oil Seals for Faceplate and Gear Case Gore-Tex Rope Gaskets High Temp. Carbon Bushings in S.S. Pumps Standard Gasket Material Class 1 Clearance Impellers Standard Carbon Bushings in S.S. Pumps Standard Pump Materials Standard Gear Case Oil Standard Packing Bronze Bushings for Ductile Iron Pumps Carbon Bushings Used in Ductile Iron Pumps High Temperature APG 250 Gear Case Oil Standard Oil Seals for Faceplate and Gear Case Standard DU Bushings for Ductile Iron Pumps PTFE Oil Seals for Faceplate and Gear Case Standard Oil Seals for Faceplate and Gear Case...

Open the catalog to page 6

WARNING Failure to follow these instructions could result in serious bodily injury or death. Do not attempt to work on any Tuthill pump installation before completing the steps below. Disconnect the drive so that it cannot be started while work is being performed. Review the Material Safety Data Sheet (MSDS) applicable to the liquid being pumped to determine its characteristics and the precautions necessary to ensure safe handling. Vent all pressure within the pump through the suction or discharge lines. All Tuthill pumps contain residual hydraulic oil from the factory production test....

Open the catalog to page 7

Packing Adjustment WARNING Packing is designed to leak. Therefore, when pumping hazardous liquids, a mechanical seal is recommended to minimize any potential source of leakage that could result in a hazardous condition. All packings must leak to perform properly. Their purpose is to control leakage—not to prevent it. The slight leakage along the shaft provides proper lubrication to the packing. Pump packings have a lubricant, which acts as a primary sealant for the start-up and breakin phases, during which this lubricant acts to reduce friction. Once the pump is on the line, external...

Open the catalog to page 8

The following charts on lubrication requirements are offered as a guide only. Common sense approach to preventative maintenance must be exercised for best pump service life. Ambient conditions (temperature, humidity, dust, etc.) can alter schedule. Gearcase First Oil Change – Hrs. Subsequent Change – Hrs. Capacity - CC 30A 500 500 3000 2A & 3A 1900 500 3000 70A & 120A 250 500 3000 330 1000 500 3000 600 1250 500 3000 Above standard lubricants are adequate for operating temperatures between –100°F and +350°F Model No. Total Grease Capacity Per Pump - CC 30 35 165 140 100 If temperature...

Open the catalog to page 9

70A, 120A, and 330 Pumps Isometric Drawing (Models Starting w/ O5 & Packing)

Open the catalog to page 10

Description Dowel Pin Cap Screw Square Key Timing Gears Driven Shaft (Armco 17-4PH) Gear Key Cap Screw Impeller Key (CI) Impeller Key (SS) Impellers (CI) S.L. Impellers (CI) D.L. Impellers (SS) S.L. Impellers (SS) D.L. Drive Shaft (Armco 17-4PH) Set Screw (CI) Set Screw (SS) Hex Head Bolt Grease Fitting Bearing Cover Lock Nut Lock Washer Ball Bearing Lip Seal Bearing Carrier Set Screw Shim --------.002” Shim --------.005” Shim --------.015” Description Faceplate (CI) Faceplate (SS) Hex Head Bolt Pipe Plug (CI) Pipe Plug (SS) V-Ring Gore-Tex Gasket Impeller Housing (CI) Impeller Housing (SS)...

Open the catalog to page 11

70A, 120A, and 330 Pumps Isometric Drawing (Models Starting w/ O5 & Tuffseals) 4

Open the catalog to page 12

Description Dowel Pin Cap Screw Square Key Timing Gears Driven Shaft (Armco 17-4PH) Gear Key Cap Screw Impeller Key (CI) Impeller Key (SS) Impellers (CI) S.L. Impellers (CI) D.L. Impellers (SS) S.L. Impellers (SS) D.L. Drive Shaft (Armco 17-4PH) Set Screw (CI) Set Screw (SS) Hex Head Bolt Grease Fitting Bearing Cover Lock Nut Lock Washer Ball Bearing Lip Seal Bearing Carrier Set Screw Shim ---------.002” Shim ---------.005” Shim ---------.015” Description Faceplate (CI) Faceplate (SS) Hex Head Bolt Pipe Plug (CI) Pipe Plug (SS) V-Ring Gore-Tex Gasket Impeller Housing (CI) Impeller Housing...

Open the catalog to page 13All Tuthill catalogs and technical brochures

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

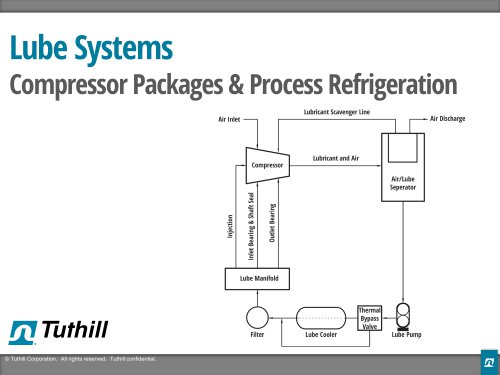

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

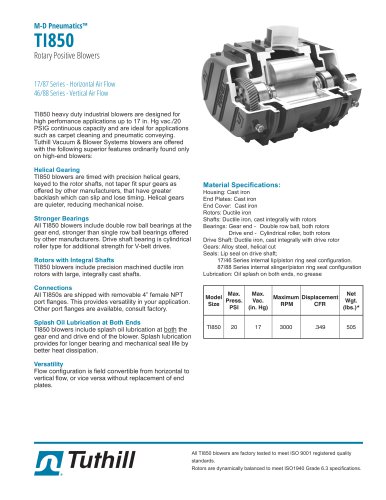

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

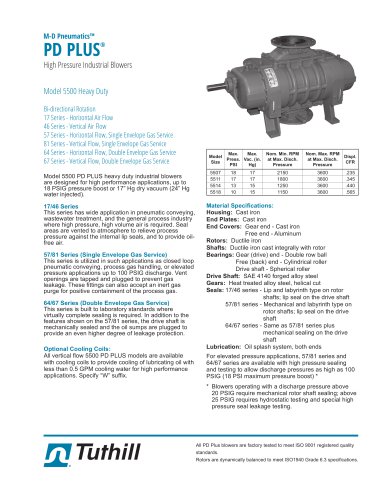

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

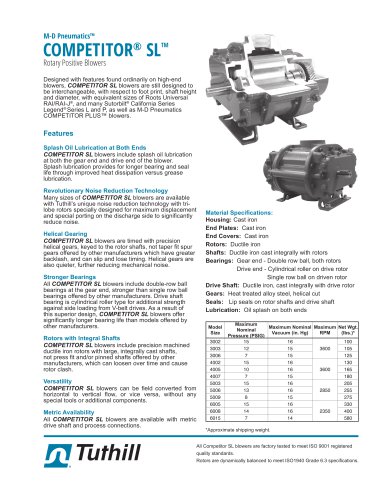

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

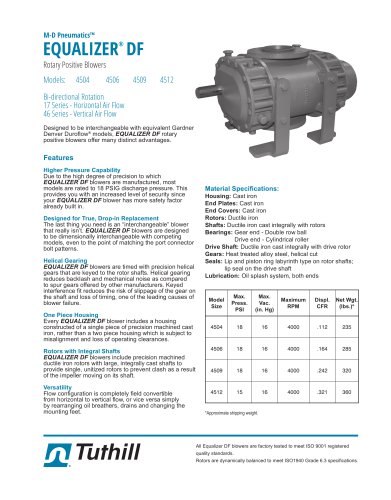

Equalizer RM TH-045

2 Pages

-

Equalizer DF TH-046

2 Pages

-

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages