Catalog excerpts

Engineering Data Pack GlobalGear® Series Pump US Excellence at work. Excellence in life.

Open the catalog to page 1

Shaft Dimensions

Open the catalog to page 3

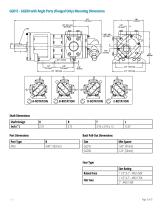

Shaft Dimensions

Open the catalog to page 4

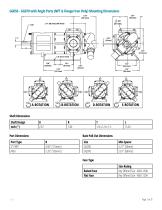

Shaft Dimensions

Open the catalog to page 5

Shaft Dimensions

Open the catalog to page 6

Shaft Dimensions

Open the catalog to page 7

Shaft Dimensions

Open the catalog to page 8

Shaft Dimensions Face Type

Open the catalog to page 9

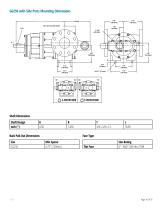

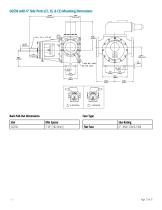

GG080 - GG090 with Side Ports (NPT & Flange) Mounting Dimensions 6.85" [174.0mm] Shaft Dimensions Shaft Design Inch (") Port Dimensions Port Type FNPT (CI) ANSI 125# /150# 2" ANSI 250# / 300# 3" ANSI 250# / 300# T 1/4 x 1/4 x 1.5 Back Pull-Out Dimensions Flat Face Note: GG080 in Cast Iron or SS (Flanged only) GG090 CI only. Raised Face

Open the catalog to page 10

Shaft Dimensions

Open the catalog to page 11

Shaft Dimensions

Open the catalog to page 12

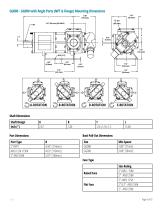

GG200 - GG210 with Angle Ports Mounting Dimensions 9.31" [236.5mm] (PRIMARY MOUNTING HOLES) Shaft Dimensions Shaft Design Inch (") Port Dimensions Port Type 2” FNPT (200 Size only) ANSI flanged Back Pull-Out Dimensions B 6.56" [167mm] 7.19" [183mm] Face Type Raised Face Flat Face

Open the catalog to page 13

Shaft Dimensions

Open the catalog to page 14

Shaft Dimensions

Open the catalog to page 15

GG250 with Side Ports Mounting Dimensions 7.09" [180.1mm] Shaft Dimensions Shaft Design Inch (") Back Pull-Out Dimensions Size GG250 Face Type Min Spacer 4.73" [120mm] Flat Face Size-Rating 4" - ANSI 125# thru 150#

Open the catalog to page 16

Back Pull-Out Dimensions Face Type

Open the catalog to page 17

Back Pull-Out Dimensions

Open the catalog to page 18

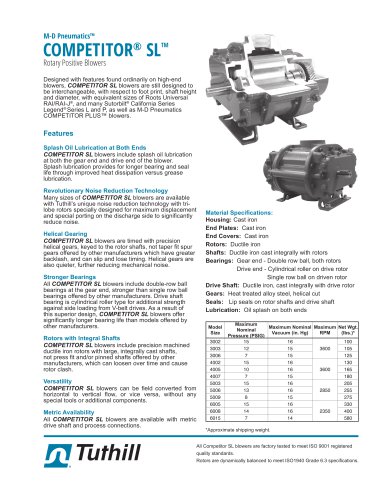

Pos. 1 & 2 - Pump Series GG = complete pump GD = drive module Pos. 3, 4, & 5 - Pump Size 015 = nominal 15 GPM at 1800 RPM 030 = nominal 30 GPM at 1800 RPM 050 = nominal 50 GPM at 1500 RPM 070 = nominal 70 GPM at 1500 RPM 080 = nominal 80 GPM at 1500 RPM 090 = nominal 90 GPM at 1500 RPM 120 = nominal 120 GPM at 1200 RPM 130 = nominal 130 GPM at 1000 RPM 200 = nominal 200 GPM at 1000 RPM 210 = nominal 210 GPM at 800 RPM 250 = nominal 200 GPM at 640 RPM 550 = nominal 550 GPM at 500 RPM Pos. 6 - Material of Construction I = iron S = stainless steel C = cast steel Pos. 7 - Port Position &...

Open the catalog to page 19

Clearances Pump Series Bushings Seal Elastomers Packing Notes: 1. A pump's performance is dependent on more than just the temperature ranges of the component materials. 2. Pumps with extra clearances may have reduced flow rates when operated at lower temperatures. 3. Pumps with PTFE seals also have PTFE-encapsulated Viton O-rings which are limited to 400 °F (204 °C). Clearance Class J = Chocolate Clearance Mods (Include Class B Clearance, Bronze Bushings, Root Drilled Idler & Drilled Rotor Head.)

Open the catalog to page 21

Mechanical Seals for 1 1/8" Shaft Viton®-Registered trademark of DuPont De Nemours & Company/Gylon®-Registered trademark of Garlock, Inc./FC=Factory Choice (Flowserve, Fluidol, John Crane, Sepco)

Open the catalog to page 23

Mechanical Seals for 1 3/8" Shaft Viton®-Registered trademark of DuPont De Nemours & Company/Gylon®-Registered trademark of Garlock, Inc./FC=Factory Choice (Flowserve, Fluidol, John Crane, Sepco)

Open the catalog to page 24

Mechanical Seals for 1 3/4" Shaft Viton®-Registered trademark of DuPont De Nemours & Company/Gylon®-Registered trademark of Garlock, Inc./FC=Factory Choice (Flowserve, Fluidol, John Crane, Sepco)

Open the catalog to page 25

Mechanical Seals for 2 3/4" Shaft Viton®-Registered trademark of DuPont De Nemours & Company/Gylon®-Registered trademark of Garlock, Inc./FC=Factory Choice (Flowserve, Fluidol, John Crane, Sepco)

Open the catalog to page 26

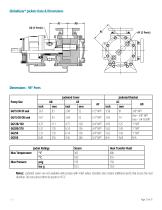

Dimensions - 90° Ports Pump Size Notes: Jacketed covers are not available with pumps with relief valves. Brackets also contain additional ports that access the seal chamber. Do not connect them to steam or H.T.F.

Open the catalog to page 31

Dimensions - 180° Ports pump size Notes: Jacketed covers are not available with pumps with relief valves. Brackets also contain additional ports that access the seal chamber. Do not connect them to steam or H.T.F.

Open the catalog to page 32

NPSHr for up to 750 ssu (Feet of Water) Notes: For viscosity above 750 ssu (165 cst), multiply the charted NPSHr value by the appropriate correction factor. NPSHa (available) must be greater than NPSHr (required) for proper pump operation. Data shown here is for pumps with standard ports. Optional ports of different sizes may affect NPSHr.

Open the catalog to page 33

GlobalGear® Flange Ratings (Cast Iron) Temperature (°C) -45 300 ANSI 250# 200 Pressure (PSIG) Note: These charts show the ratings for flanges only - the maximum pump operating conditions must also be checked. Consult the appropriate Tuthill catalog for maximum allowable operating pressures and temperatures, based on pump application conditions and pump features. These ratings are based on non-shock pressures. ANSI data is from ASME/ANSI B16.1 - 1989 (class A). Consult this spec for more information. ISO data is from ISO 7005-2 : 1988 (gray iron). Consult this spec for more information....

Open the catalog to page 34

Notes: We always recommend proper pipe support. Hydraulic Institute standards state, "... both suction and discharge piping should be independently supported near the pump so that when the flange bolts are tightened, no strain will be transmitted to the pump casing." For GG Iron Series, multiply the above values by 0.35. These maximum values are not valid for combined forces and moments. Excellence at work. Excellence in life. Tuthill Pump Group USA • United Kingdom • China www.tuthillpump.com

Open the catalog to page 35All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

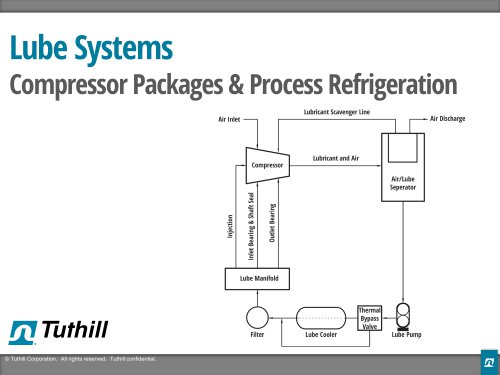

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

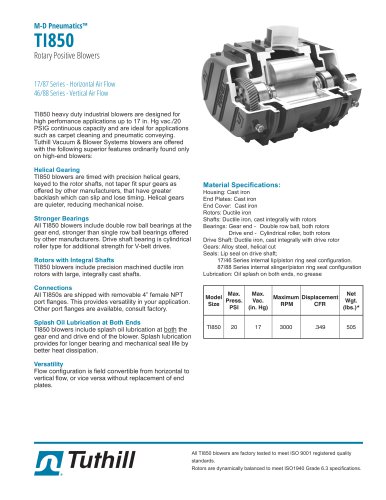

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

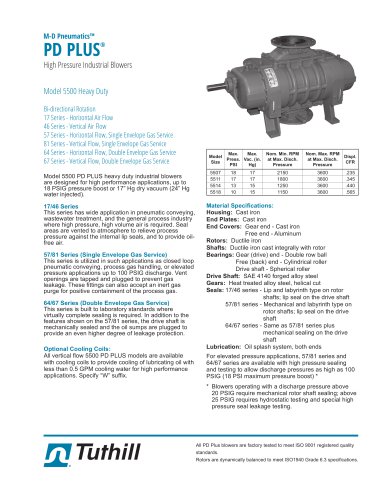

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

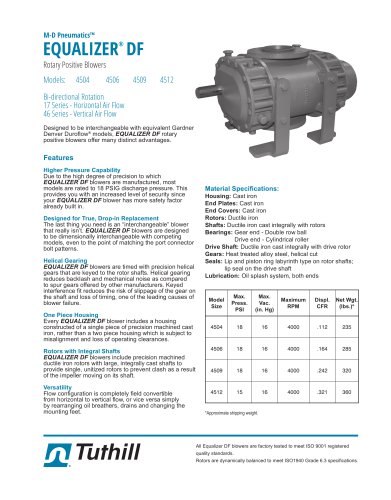

Equalizer DF TH-046

2 Pages

-

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages