Catalog excerpts

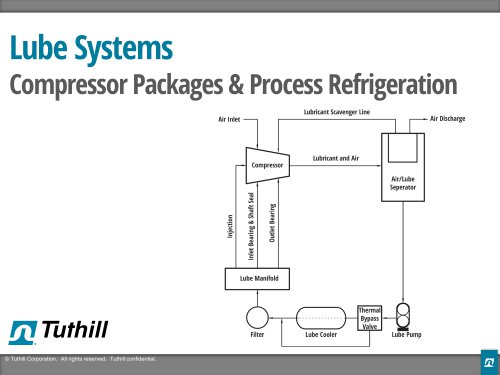

Tuthill Process Pumps Products Marketing Report Report # 4 (Rev. 04/09/06) Internal Gear Pumps for Compressor Package Lubrication Systems Compressor Applications Overview Tuthill is a leading manufacturer of pumps for compressor lubrication services. Larger flows and pressures are addressed with the modular GlobalGear line of internal gear pumps. The GlobalGear is a heavy-duty internal gear pump that features an external thrust bearing and heavy-duty bracket for supporting bearings and mechanical seals. Lower flows are addressed with the L & C series of products that includes a wide range of integral close-coupled pumps and motors, and CC series of flanged-mounted pumps for use with NEMA C faced motors. The compressors themselves are mechanical devices that use rotors in a housing to increase pressure by forcing gas from a larger cavity to a smaller cavity. Lubrication systems are critical for compressors. Bearings and seals must be cooled and lubricated. Compressing gas generates heat, and for many compressor designs and processes, this heat must be removed. Lubrication systems circulate oil for lubricating and cooling the bearings, and in some designs, the oil is used to cool the gas. Figure 1 shows a view of a typical screw compressor. Tuthill Pump has been supplying lubrication pumps for seventy-five years and has earned a solid reputation for supplying long-lasting, reliable pumps. Compressor Package Systems There is a growing market for compressor packages for the oil and gas market and for process refrigeration. Compressors are used for injecting compressed natural gas into wells for better oil extraction, for pipeline transportation of natural gas, and for process cooling. The compressors are very large, being driven by substantial size engines or electric motors. Figure 1: View of Typical Screw Compressor The compressor is the major component of an integrated package. The integrated package consists of a driver, that is, an engine or motor, and is sometimes supplied with a gear reducer. Within the package there is lubrication system that consists of a pump, heat exchanger for oil cooling, filter, and oil separator for separating the oil from gas. Figure 2 is a flowchart showing a schematic of the lubrication system. Page 1

Open the catalog to page 1

Figure 2: Schematic of the Lubrication System The entire package may be quite large, and in many instances, as large as a good size home. Figure 3 is a view of an entire compressor package. Some of the compressor manufacturers offer the entire package. Many of these systems are supplied by package builders that specialize in building large scale compressor systems. The systems are often customized to the application. Figure 3: View of Complete Package System (Toromont)

Open the catalog to page 2

These systems are often installed in remote locations where there is very limited availability of maintenance staff. Operating conditions can be severe with extreme hot or cold ambient temperatures, dust, and ever present vibration. GlobalGear was designed to be a very low maintenance pump. GlobalGear uses a sealed bearing that requires no lubrication. The leading competitor uses greased bearings that must be lubricated every 500 hours of operation, and the lip seals used to retain the grease have an effective life of approximately 1500 hours of operation. End clearance is maintained in...

Open the catalog to page 3

Also, to reliabily adapt to the high pressure requirements for this market, a high pressure cartridge seal is used with silicon carbide on silicon carbide faces. The John Crane 5600 series seal that is used has essentially the same chasis and internals as the 5600 series seals that have been qualified for API 682 compliant category 1 designs. Figure 5 shows a view of the rugged gland and heavy duty construction of the mechanical seal. practice is to verify O-ring compatibility with the intended lubricant manufacturer. Where requested, to address concerns with hazards associated with...

Open the catalog to page 4All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

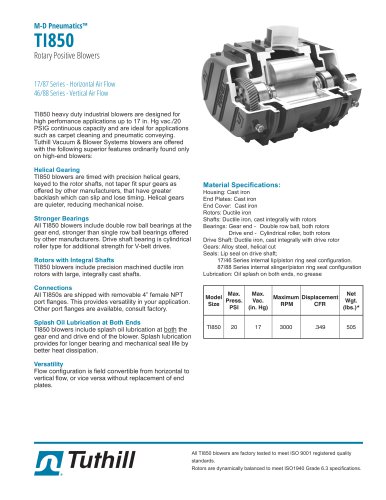

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

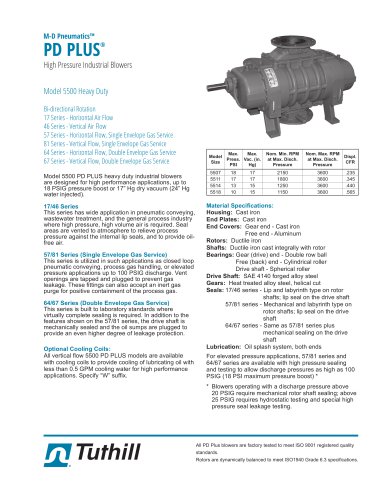

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

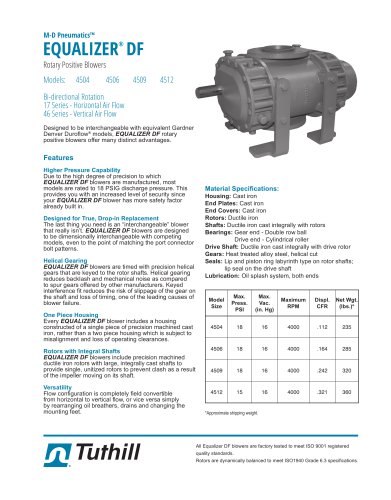

Equalizer DF TH-046

2 Pages

-

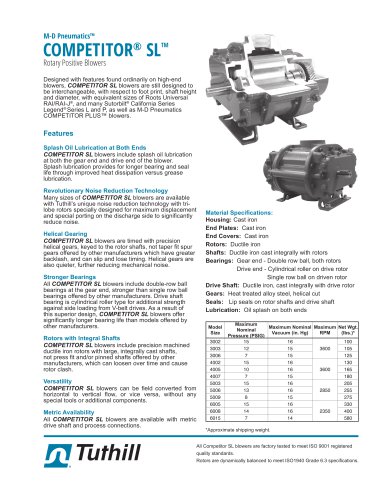

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages