Catalog excerpts

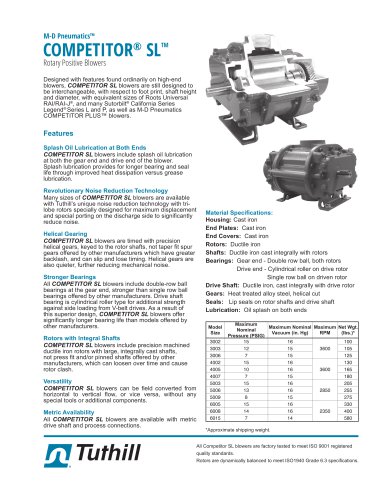

Rotary Positive Blowers Designed with features found ordinarily on high-end blowers, COMPETITOR SL blowers are still designed to be interchangeable, with respect to foot print, shaft height and diameter, with equivalent sizes of Roots Universal RAI/RAI-J®, and many Sutorbilt® California Series Legend® Series L and P, as well as M-D Pneumatics COMPETITOR PLUS™ blowers. Features Splash Oil Lubrication at Both Ends COMPETITOR SL blowers include splash oil lubrication at both the gear end and drive end of the blower. Splash lubrication provides for longer bearing and seal life through improved heat dissipation versus grease lubrication. Revolutionary Noise Reduction Technology Many sizes of COMPETITOR SL blowers are available with Tuthill’s unique noise reduction technology with trilobe rotors specially designed for maximum displacement and special porting on the discharge side to significantly reduce noise. Helical Gearing COMPETITOR SL blowers are timed with precision helical gears, keyed to the rotor shafts, not taper fit spur gears offered by other manufacturers which have greater backlash, and can slip and lose timing. Helical gears are also quieter, further reducing mechanical noise. Stronger Bearings All COMPETITOR SL blowers include double-row ball bearings at the gear end, stronger than single row ball bearings offered by other manufacturers. Drive shaft bearing is cylindrical roller type for additional strength against side loading from V-belt drives. As a result of this superior design, COMPETITOR SL blowers offer significantly longer bearing life than models offered by other manufacturers. Material Specifications: Housing: Cast iron End Plates: Cast iron End Covers: Cast iron Rotors: Ductile iron Shafts: Ductile iron cast integrally with rotors Bearings: Gear end - Double row ball, both rotors Drive end - Cylindrical roller on drive rotor Single row ball on driven rotor Drive Shaft: Ductile iron, cast integrally with drive rotor Gears: Heat treated alloy steel, helical cut Seals: Lip seals on rotor shafts and drive shaft Lubrication: Oil splash on both ends Model Size Rotors with Integral Shafts COMPETITOR SL blowers include precision machined ductile iron rotors with large, integrally cast shafts, not press fit and/or pinned shafts offered by other manufacturers, which can loosen over time and cause rotor clash. Versatility COMPETITOR SL blowers can be field converted from horizontal to vertical flow, or vice versa, without any special tools or additional components. Metric Availability All COMPETITOR SL blowers are available with metric drive shaft and process connections. *Approximate shipping weight. All Competitor SL blowers are factory tested to meet ISO 9001 registered quality standards. Rotors are dynamically balanced to meet ISO1940 Grade 6.3 specifications.

Open the catalog to page 1

Performance Pressure performance is based on inlet conditions of 1.02 kgf/cm² A and 20° C. Vacuum performance is based on inlet temperature of 20° C and discharge pressure of 1.02 kgf/cm² A. In conjunction with our program of continuous testing and upgrading, all specifications are subject to change without notice. All data are approximate. Request a quotation for your specific application. Blower Model 8 PSIG 10 PSIG 12 PSIG 13 PSIG 15 PSIG SPEED 7 PSIG (RPM) CFM HP CFM HP CFM HP CFM HP CFM HP CFM HP 20 47 134 Dimensions Model Style Size Values shown are approximate and should not be used...

Open the catalog to page 2All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

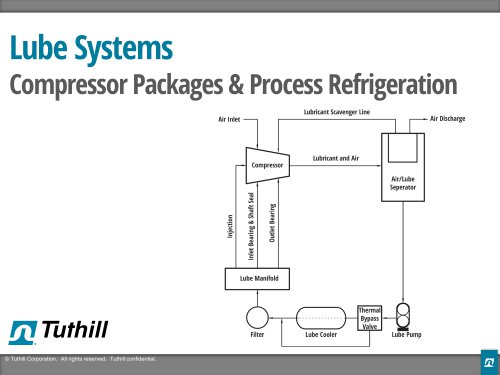

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

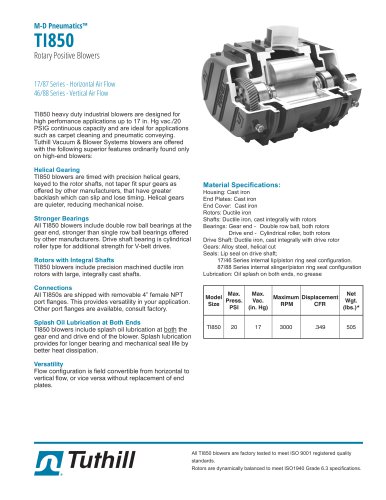

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

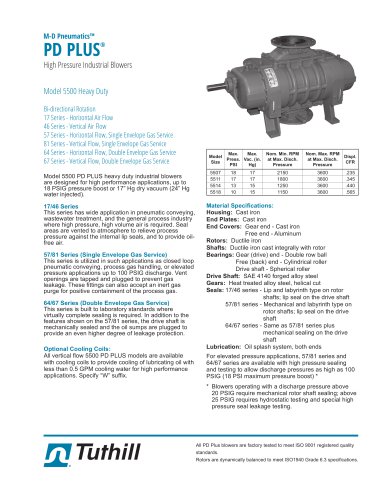

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

Equalizer DF TH-046

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages