Catalog excerpts

ATLANTIC FLUIDICS LIQUID RING PUMPS AND SYSTEMS

Open the catalog to page 1

ATLANTIC FLUIDICS® Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Pump Specifications . . . . . . . . . . . . . . . . . . . . . .5 Systems Overview . . . . . . . . . . . . . . . . . . . . . . . .9 Oil Sealed Systems . . . . . . . . . . . . . . . . . . . . . . .11 Environmental Remediation Systems . .12 Booster/Liquid Ring Systems . . . . . . . . . . .13 Central Vacuum Systems . . . . . . . . . . . . . . .14 Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15...

Open the catalog to page 2

ATLANTIC FLUIDICS® THE REVOLUTIONARY ATLANTIC FLUIDICS® PUMP DESIGN Introducing the Atlantic Fluidics Liquid Ring Vacuum Pump, featuring the proprietary Fluid-Vac® axial flow design. This rugged, compact-design pump generates the highest vacuum of any comparable liquid ring pump. A fixed port cylinder, concentric with the rotor bore, directs the gas along the shaft axis, into the suction ports of the rotor and finally back through the rotor and rear of the pump for discharge. Because the gas flow is along the motor shaft (and not at right angles), the pump can start flooded, without damage....

Open the catalog to page 3

ATLANTIC FLUIDICS® Function of Atlantic Fluidics® Liquid Ring Vacuum Pump Casting, Molding and Forming Evacuation of molds, degassification of molten materials Rubber, plastics, metals, wood products, veneers Vacuum pickup, handling, positioning and holding Glass, sheet products, small parts, auto windshields, aircraft surfaces, beverage cans, sawmill operations Cooling & Chilling Rapid evaporation of moisture content Fruits & vegetables, potato salad Deaeration & Degassification Water, rubber products, oils, plastics, molten metals, beverages Removal of condensable vapors Transformers,...

Open the catalog to page 4

ATLANTIC FLUIDICS® PRINCIPLE OF OPERATION Atlantic Fluidics® Vacuum Pumps GAS OUT consist of a shrouded motor rotatCASING ing freely within an eccentric casing. There is no metal-to-metal INLET PORT contact between the rotor and the casing. Centrifugal force acting on liquid within the pump causes the liquid to form a ring inside the casing. A fixed port cylinder concentric with the rotor directs the gas into the suction ports. Gas is trapped between the blades by the liquid pistons formed by centrifugal force as the liquid recedes from the port cylinder. It is trapped GAS SUCTION at the...

Open the catalog to page 5

ATLANTIC FLUIDICS® “A” SERIES SINGLE-STAGE PUMPS Closed-coupled Designs A B INLET NPT 4 HOLES TAPPED 5/8"-11 INLET 2" FL. Pedestal Mount MODEL WEIGHT lbs./kg WEIGHT lbs./kg WEIGHT lbs./kg

Open the catalog to page 6

ATLANTIC FLUIDICS® “A” SERIES SINGLE-STAGE PUMPS PERFORMANCE CURVES PERFORMANCE CURVES PERFORMANCE CURVES Capacity (ACFM) Performance curves are based on dry air at 68°F (20°C), 60°F (15°C) seal water, and 29.92 inches of mercury (760 torr) barometric pressure.

Open the catalog to page 7

ATLANTIC FLUIDICS® “T” SERIES MULTI-STAGE PUMPS Atlantic Fluidics® “T” Series Multi-stage Liquid Ring Vacuum Pumps utilize the same axial flow design as the “A” Series Single-stage pumps, but with an additional stage to provide deeper vacuum levels. This patented pump style is designed for high wet vacuum applications where they can operate with the lowest partial gas pressure without cavitation. Ideally suited for evaporators, deaerators, autoclaves, dryers and other applications requiring vacuum higher than 27 In. Hg. When packaged in oil sealed systems, “T” Series pumps can operate in...

Open the catalog to page 8

ATLANTIC FLUIDICS® An important consideration in planning a liquid ring vacuum pump installation is the design of the sealant system and its effect on the performance of the pump. TVS recommends early consideration be given to sealant system design because there are several elements of pump sizing, selection and system design that will be affected by the choice of the sealant system. Operating pressure is affected by sealant temperature, flow rate, specific heat, density and viscosity The gas load may influence the selection of the sealant and the sealant system The economic priorities may...

Open the catalog to page 9

ATLANTIC FLUIDICS® The Partial-sealant Recovery System discharges water and gas into a gas/liquid separator tank. The gas vents from the top of the tank, while the water is retained. Approximately half of the water is disposed through an overflow; the remainder re-circulates back through the pump. Fresh water is added to maintain proper sealing water temperature. In order to keep the amount of make-up water to a minimum, the system may be fitted with a temperature modulation valve. A100 AIR COOLED FULL-SEALANT RECOVERY The Full-sealant Recovery System (pictured) is a closed-loop system. The...

Open the catalog to page 10

ATLANTIC FLUIDICS® Atlantic Fluidics® Series OSR Oil Sealed Liquid Ring Vacuum Pump Systems come completely assembled in a compact design, mounted on a steel base plate. All systems are rigorously tested and painted prior to shipment. FEATURES: Higher vacuum than with water sealed systems Compact design Completely self-contained Easy to install and maintain Designed for long life Fully assembled and tested Series OSR Systems feature the close-coupled Atlantic Fluidics Liquid Ring Vacuum Pump with TEFC motor and the following components: • Air cooled heat exchanger • Oil reservoir/separator...

Open the catalog to page 11

ATLANTIC FLUIDICS® 12 ENVIRONMENTAL REMEDIATION SYSTEMS Since 1981, Atlantic Fluidics® Vacuum Pump Systems have been used in demanding environmental remediation applications around the world. In 1988, the Series EWP Fluid-Vac® Environmental Remediation System was developed to address the logistical challenges of engineering and installing a liquid ring system on-site in the field. This pioneering design effort has made Tuthill Vacuum Systems a leader in the use of liquid ring vacuum pump technology in environmental restoration applications. Today, Tuthill Vacuum Systems offers two styles of...

Open the catalog to page 12All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

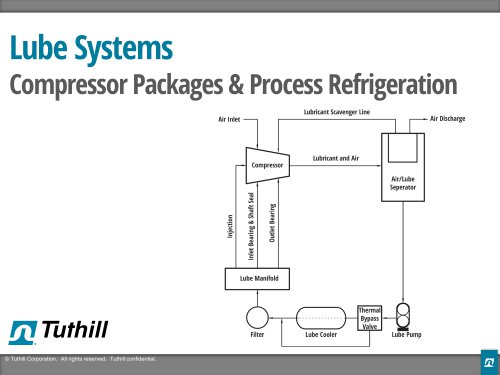

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

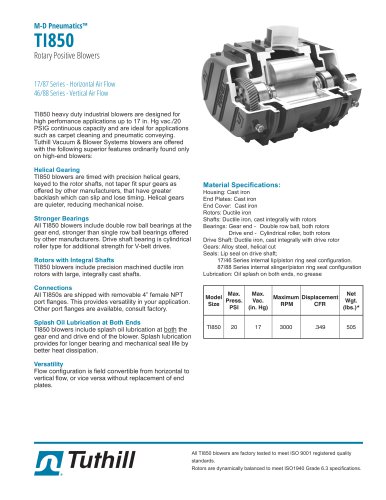

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

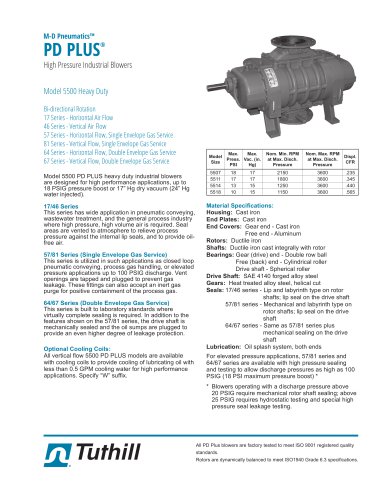

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

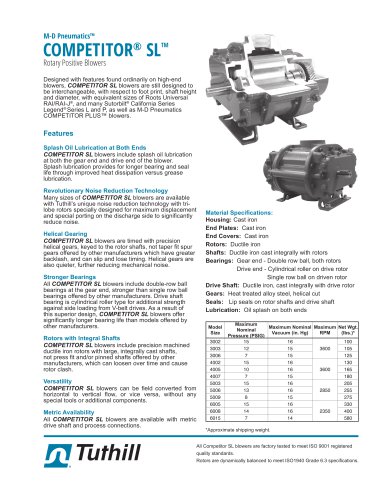

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

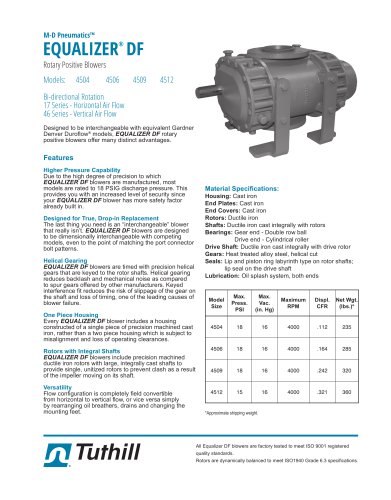

Equalizer DF TH-046

2 Pages

-

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages