Catalog excerpts

Installation and Service Instructions 4000 Series Pumps Excellence at work. Excellence in life.

Open the catalog to page 1

Table of Contents Introduction General Description Contact Information Proper Installation Relief Valve Protection Strainer Protection Seal Replacement Pump Disassembly Pump Assembly Changing Rotation Seal Replacement Seal Replacement and Resetting of Clearances Pump Disassembly Pump Assembly Changing Suction Ports While Maintaining Shaft Rotation 14 Changing Shaft Rotation While Maintaining Suction Ports 15 Changing Suction Ports While Changing Shaft Rotation Troubleshooting Material Returns Version

Open the catalog to page 2

Introduction The 4000 Series pumps have been certified to the requirements of the ATEX Directive 94/9/EC for use in Category II, Group 2 G applications. Read this manual before operating or working on the 4000 Series pumps. If additional information is required to facilitate operation or maintenance, contact the authorized Tuthill distributor shown at the back of this service manual. 4100 & 4300 Series pumps are compact, highly efficient, cast iron, positive displacement rotary pumps with mechanical seals and have been designed and manufactured to provide years of service under normal...

Open the catalog to page 3

The Pumping Principle Tuthill 4000 Series cast iron pumps employ the internal gear pumping principle. There are only two moving parts. Pumping action is based on a rotor, idler gear, and crescentshaped partition cast integral with the cover. Power applied to the rotor is transmitted to the idler gear with which it meshes. The space between the outside diameter of the idler and the inside diameter of the rotor is sealed by the crescent. As the pump starts, the teeth come out of mesh, increasing the volume. This creates partial vacuum, drawing the liquid into the pump through the suction...

Open the catalog to page 4

Proper Installation Unsatisfactory pump installations are usually characterized by poor suction conditions for the specific liquid being handled. Suction conditions should be minimized to prevent vaporization of the liquid. If vacuum conditions force the liquid to vaporize, cavitation will occur, resulting in loss of capacity, premature wear and noisy operation. When handling high viscosity liquids, the speed of the pump must be reduced and the size of the lines increased to prevent cavitation. Note: Pipeline friction increases at a rapid rate with an increase in viscosity. For a given pump...

Open the catalog to page 5

Relief Valve Protection All 4000 Series models are positive displacement pumps. As the pump rotates, liquid is positively delivered to the discharge side of the pump. If the discharge line is closed off, pressure will increase until the drive stalls and/or fails, the pump breaks or ruptures, or the piping bursts. To prevent this from happening, the use of a pressure relief valve is required. A relief valve that directs the flow back to the supply tank is recommended. The internal relief valve available on 4000 Series pumps is designed for overpressure protection only. It is not intended as...

Open the catalog to page 6

Strainer Protection Strainers are used to remove contaminated particles from the fluid system and extend pump life. Every pump should be protected from these particles by a strainer in the suction line. Strainer size and mesh of screen are determined by the rate of flow and viscosity of the fluid. Consult the strainer manufacturer for recommendations. Never use a strainer with a built-in automatic by-pass on the suction line set to open under 30” Hg. vacuum. Install the strainer according to the designated direction of flow, locating it so that it is accessible for servicing. Use a duplex...

Open the catalog to page 7

Description Housing Cover Assembly Idler Gear Cover Screws Cover Gasket Housing Bushing Item Description 7 Retaining Ring* 8 Mechanical Seal 9 O’Ring 10 Housing Plug 11 Rotor * Models 4101/4121, 4102/4122, 4103/4123 & 4104/4124 only. Page 8 of 18

Open the catalog to page 8

Seal Replacement The seal assembly in 4100/4120 pumps can be changed without disassembly of the rest of the pump. • Place the pump in a vise with the shaft facing up so that one jaw grips across the two ports. Do not tighten excessively as the pump housing may become distorted. • Inspect the shaft at the keyway, flat or tang. Any burrs will interfere with removal of the housing plug and bearing assembly. • Remove the housing plug with a face-type spanner wrench, available from Tuthill as part number 0L506. • Remove the seal from the shaft. The rubber boot will be bonded to the shaft, so it...

Open the catalog to page 9

Pump Disassembly • Follow steps 1-5 from “Seal Replacement” above to remove the seal assembly • On models 4101/4121, 4102/4122, 4103/4123, and 4104/4145, remove the retaining ring from the shaft • Mark the cover and housing of the pump for proper re-assembly • Remove the cover screws, cover, idler and rotor form the housing. Inspection • Check the housing, rotor, idler gear, idler pin and cover for wear and chipped or broken teeth. There must not be any deep scratches or grooves on any of the following. • The ID surface of the housing • The OD of the rotor • The end face of the rotor • The...

Open the catalog to page 10

Description Cover Housing Bracket Idler Gear Seal Gland Rotor O-Ring O-Ring Description Mechanical Seal Retaining Ring Cover Screws Nut Cover Screws Lockwasher Gland Screws Seal Replacement • Grip the pump firmly across the ports and secure the housing in a vise with the shaft end up • Remove any burrs or nicks on the shaft. Use a small, fine file if needed • Remove the seal gland cap screws • Slide the seal gland cap off the shaft • Remove the stationary seat of the seal from the seal gland • Slide the seal cartridge off the shaft • Polish the pump shaft with crocus cloth or very fine...

Open the catalog to page 11

Description Cover Housing Bracket Idler Gear Seal Gland Adjusting Sleeve Rotor O-Ring O-Ring Mechanical Seal Description Retaining Ring Thrust Washer Thrust Bearing Lip Seal Set Screw Cover Screws Nut Cover Screws Lockwasher Gland Screws

Open the catalog to page 12

Seal Replacement and Resetting of Clearances 1. Grip the pump firmly across the ports and opposite side of the housing in a vise with the shaft end up. 2. Remove any burrs or nicks on the shaft. Use a small, fine file if needed. 3. Remove the lip seal from the adjustment sleeve. 4. Loosen the setscrew in the adjustment sleeve. 5. Rotate the adjustment sleeve clockwise until it makes contact with the housing plug. 6. Remove the retaining ring from the shaft. 7. Remove the cap screws at the shaft end. 8. Slide the housing plug and thrust bearing off the shaft. 9. Remove the stationary seat of...

Open the catalog to page 13All Tuthill catalogs and technical brochures

-

HD Series Pumps

39 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

GlobalGear® Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

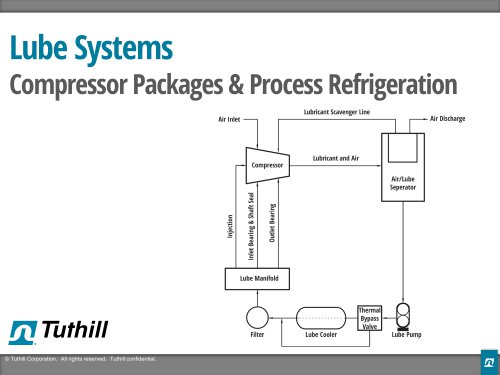

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

Heavy Duty Series

6 Pages

-

2016 D, T, & P SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

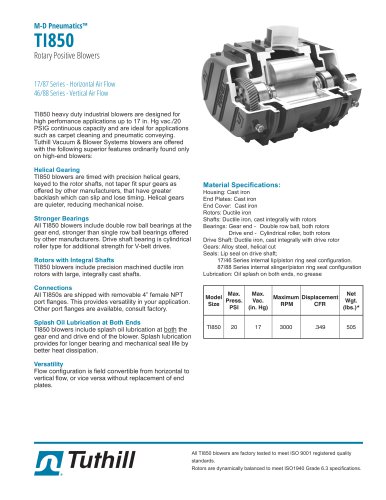

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

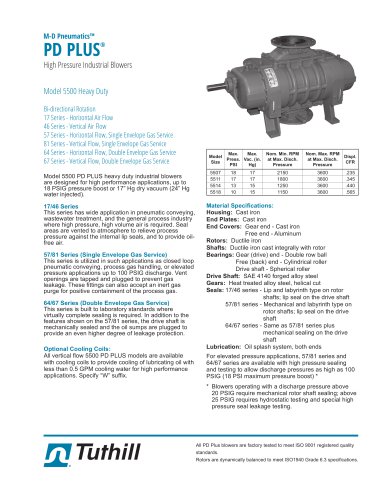

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

Equalizer RM TH-045

2 Pages

-

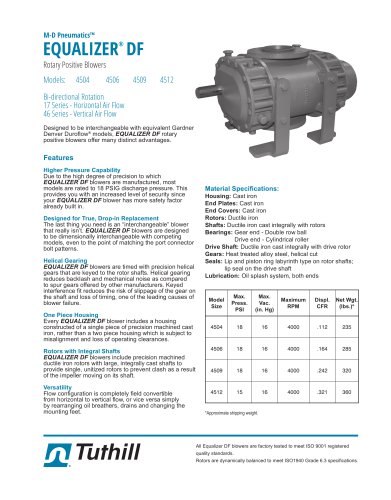

Equalizer DF TH-046

2 Pages

-

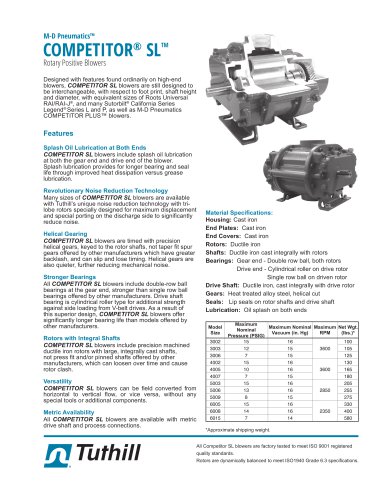

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

GlobalGear® Series

6 Pages

-

2015 D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages