Catalog excerpts

New grooving and parting off tools Extended version with new items Wide variety of tools drastically reduce set up time!

Open the catalog to page 1

Features Feature of My T series My-T G series For aluminium Reduce cutting force and chip welding due to the combination of sharp chipbreaker and ne grain cemented carbide. Lower cutting resistance and better cutting action than GE type. Used for internal grooving when problems with chip control and chattering occur. Larger width of chipbreaker than GE type and with good chip control. Used for face grooving when problems with chip control and chattering occur. Width: 2.0 ~ 5.0 mm ◆External grooving ◆Parting off Width: 2.0 ~ 5.0 mm ◆External grooving ◆Internal grooving ◆Face grooving...

Open the catalog to page 2

My-T G series WGE, GE type inserts almighty chipbreaker ¡Excellent chip control for external grooving, internal grooving Specialist of grooving ¡GN type for internal grooving, GF type for face grooving, WGT, GT type for traversing and WGR, GR type for proling. ¡Min. bore dia: ø25 mm for internal grooving, ø30 mm for face grooving. ¡Possible to reduce cost by tool concentration ¡Interchangeable blades t into all toolholder systems of My-T G series. My-T CGD series ¡Two corner type inserts. For internal grooving Min. bore dia. ø25 ¡G-class inserts which excels in accuracy of cutting edge...

Open the catalog to page 3

Chipbreaker recommendation for applications Basic recommendation External Complementary recommendation Parting off Traversing Proling Parting off Traversing Proling Face grooving Internal grooving For Aluminium alloys, Non-ferrous metals

Open the catalog to page 4

Grades Grades Coating layer Substrate Specic gravity Transverse rupture strength (GPa) CVD coated grade, Continuously formed columnar crystal TiCN 2 + AR O3 Coating layer demonstrates the incredible adhesion strength due to the Double-Bridge effect. Exclusive substrate delivers an outstanding balance of wear and chipping resistance. Main composition “Premium – Coat” PVD coated grade combined with tough and ne carbide substrate. Provides high reliability and stable long tool life in small parts machining at the lower cutting speed condition. Versatile cermet grade with incredible fracture...

Open the catalog to page 5

Grades Coated For parting off (handed insert) For parting off (handed insert) For external grooving and parting off Right hand (R) shown. Grades Coated Cermet T9125 GH730 NS9530 Grades Coated Cermet Grades Coated Right hand (R) shown. Grades Coated Stocked items.

Open the catalog to page 6

For face grooving (Improved chip control) For aluminium and non-ferrous metals Parts (Mono block type) (Blade type) Clamping screw Clamping screw Blade xing screw Wrench Cat. No. CGWSR/Lᮀᮀᮀᮀ-ᮀᮀ-W CGWSR/Lᮀᮀᮀᮀ-ᮀᮀ-W-L CGWSR/Lᮀᮀᮀᮀ-ᮀᮀWGR/L CGWSR/Lᮀᮀᮀᮀ-ᮀᮀWGR/L-L Standard cutting conditions Cutting speed Work materials Low carbon steels Alloy steels ( ~ 150HB) Medium carbon steels Alloy steels (150 ~ 250HB) High carbon steels Alloy steels (250HB ~ ) Stainless steels Grey and ductile cast irons Aluminium alloys, Non-ferrous metals Recommended grade Grooving (GEᮀᮀ) Traversing (GTᮀᮀ) Proling (GRᮀᮀ)...

Open the catalog to page 7

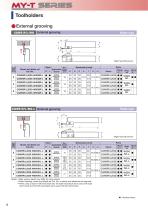

Toolholders External grooving CGWS R/L-WG External grooving Blade type Right hand (R) shown. Stock Shank and blade set Cat. No. Blade type CGWS R/L-WG-L External grooving Right hand (R) shown. Stock Shank and blade set Cat. No. Notes: • Max. groove depth may differ by using inserts. • When ordering, shank and blade set Cat. No. or shank and blade set are required. • When using a right or left hand blade set, the right hand blade set is used with right hand shank and the left hand blade set is used with left hand shank.

Open the catalog to page 8

External grooving Mono block without offset Right hand (R) shown. Groove width W (mm) CGWS R/L-W-L Applicable inserts Mono block without offset External deep grooving Right hand (R) shown. Groove width W (mm) Applicable inserts Note: Max. groove depth may differ by using inserts. ᭹ : Stocked items.

Open the catalog to page 9

CGWS R/L-G External grooving Toolholders (S: Vertical type) Stock Shank and blade set Cat. No. Right hand (R) shown. The dashed line shows 20 mm-square shank tools . Notes: • When ordering, shank and blade set Cat. No. or shank and blade set are required. • When using a right or left hand blade set, the right hand blade set is used with right hand shank and the left hand blade set is used with left hand shank. Toolholders (T: Horizontal type) External grooving Right hand (R) shown. The dashed line shows 20 mm-square shank tools . Notes: • When ordering, shank and blade set Cat. No. or shank...

Open the catalog to page 10

Toolholders (Mono block type) External grooving Right hand (R) shown. ¡Without offset Groove width W (mm) Applicable inserts Toolholders (Mono block type) External deep grooving Right hand (R) shown. ¡Without offset Groove width W (mm) Applicable inserts Note: Max. groove depth may differ by using inserts. ᭹ : Stocked items.

Open the catalog to page 11

Toolholders (S: Vertical type ) External grooving Right hand (R) shown. The dashed line shows 20 mm square shank tools. Stock Applicable Max. Max. groove parting inserts depth off dia. b R L (mm) (mm) Notes: • When ordering, shank and blade set Cat. No. or shank and blade set are required. • When using a right or left hand blade set, the right hand blade set is used with right hand shank and the left hand blade set is used with left hand shank. Toolholders (T: Horizontal type) External grooving Max. parting off dia. is different than CGWSR/L type. Right hand (R) shown. The dashed line shows...

Open the catalog to page 12

Applicable inserts Grades Note: Please contact us when ordering special sizes (2.0 - 8.5 mm). Parts Blade Clamping screw Spring Wrench Applicable insert Clamp Insert CGWSR/Lᮀᮀᮀᮀ -CGDR/Lᮀ Standard cutting conditions Grooving Low carbon steels Grooving Medium carbon steels Groove width: W (mm) Feed: f (mm/rev) Cutting speed vc (m/min) Toolholders (S: Vertical type ) External grooving 2020 shank type shown b Right hand (R) shown. Shank and blade set Cat. No. Applicable inserts Cutting edge height Notes: • When ordering, shank and blade set Cat. No. or shank and blade set are required. • When...

Open the catalog to page 13All Tungaloy Germany catalogs and technical brochures

-

NS9530 - GT9530

68 Pages

-

TUNGHOLD

156 Pages

-

T6100 - AH 600

20 Pages

-

General Catalogue cutting tools

966 Pages

-

New Procucts 2013

24 Pages

Archived catalogs

-

Stream Jet Bars

40 Pages

-

boring tool-holder

26 Pages

-

carbide milling cutter

8 Pages

-

carbide drilling tool

8 Pages

-

CBN cutting insert

16 Pages

-

carbide cutting insert

20 Pages

-

45° & 90° Milling cutter

12 Pages

-

Milling grade series T3130

6 Pages

-

Hybrid TAC MILL series

14 Pages