Catalog excerpts

Worm Gear Winches Because Tough Enough Is Never Enough.

Open the catalog to page 1

Strength You Can Depend On TWGfgjk POWER to Move the Wbr/d™ * !□ DOVER) comhuw RUFNEK® worm gear winches are backed by the strength of TWG, a global leader in standard and engineered winch, gearbox and load information systems for the Crane, Construction and Truck Equipment markets. From our state-of-the-art manufacturing facilities in Oklahoma, TWG engineers and produces equipment and components relied on by the world's largest industries. Headquartered in Tulsa, Oklahoma, TWG is comprised of six companies that specialize in industry-specific winches and supporting electronic systems. They...

Open the catalog to page 2

You Want a Winch That Works as Hard as You Do So why would you trust your oilfield fleet to anything but RUFNEK® winches? At Tulsa Winch, we take performance seriously— and it shows. Our RUFNEK® worm gear winches are as rugged and reliable as their name, and engineered to deliver the extra long life today's fleet managers demand. Unlike other winches, RUFNEK® worm gear winches are designed from the very start to perform under the toughest conditions and the harshest terrains. We manufacture our heavy-duty winches and accessories with the quality construction and outstanding strength you...

Open the catalog to page 3

At TWG, we continue to raise the bar on how winches should perform—and it's been that way for more than 75 years. RUFNEK® worm gear winches are specifically designed for the world's Oilfield Industry. In the harshest terrains, on the most challenging projects, RUFNEK® worm gear winches set a new benchmark for safe, reliable operation and rugged performance. RUFNEK® Worm Gear Winches Advanced Features and Superior Benefits Mechanical input or integral hydraulic motor and air control packages for clutch and band brake operation. Offers optimal flexibility in selecting appropriate drives...

Open the catalog to page 4

rkRUFNEK* Strong, durable, long lasting. Rufnek® worm gear winches are built for tough oilfield and heavy haul applications and available in pulling capacities from 10,000 to 130,000 pounds. Rufnek® Worm Gear Winches

Open the catalog to page 5

Worm Gear Winches Pulling Capacity Approximate weight: 215 lb Mechanical /227 lb Hydraulic HYDRAULIC PERFORMANCE daTA Layer Linepull Linespeed Cable Cap. – .4375”ø (lb) (kg) (fpm) (mpm) (ft) (m) I nput Torque-Static InputTorque-Dynamic Input Speed (lb-in) (Nm) (lb-in) (Nm) (rpm) Mechanical drive Hydraulic drive

Open the catalog to page 6

15,000 lb.Pulling CapacityHYDRAULIC PERFORMANCE DATA MECHANICAL DRIVE RUFNEK® Worm Gear Winches R^J15^W

Open the catalog to page 7

Worm Gear Winches Pulling Capacity Approximate weight: 520 lb Mechanical /545 lb Hydraulic HYDRAULIC PERFORMANCE daTA Layer Linepull Linespeed Cable Cap. – .625”ø (lb) (kg) (fpm) (mpm) (ft) (m) Mechanical drive I nput Torque-Static InputTorque-Dynamic Input Speed (lb-in) (Nm) (lb-in) (Nm) (rpm) Hydraulic drive

Open the catalog to page 8

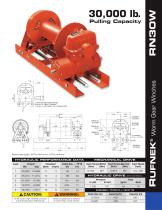

30,000 lb.Pulling Capacity Approximate weight: 650 lb Mechanical /678 lb Hydraulic RUFNEK® Worm Gear Winches R^J30^W

Open the catalog to page 9

Worm Gear Winches Pulling Capacity Approximate weight: 1,076 lb Mechanical /1,138 lb Hydraulic HYDRAULIC PERFORMANCE daTA Layer Linepull Linespeed Cable Cap. – .875”ø (lb) (kg) (fpm) (mpm) (ft) (m) Mechanical drive I nput Torque-Static InputTorque-Dynamic Input Speed (lb-in) (Nm) (lb-in) (Nm) (rpm) Hydraulic drive

Open the catalog to page 10

Approximate weight: 1,346 lb Mechanical /1,441 lb Hydraulic HYDRAULIC PERFORMANCE DATA MECHANICAL DRIVE Layer RUFNEK® Worm Gear Winches R^J65^W *Layer does not meet SAE J706 Requirement

Open the catalog to page 11

RUFNEK@ Worm Gear Winches R^J100^W HYDRAULIC PERFORMANCE DATA MECHANICAL DRIVE 100,000 lb.Pulling Capacity Input Torque-Static InputTorque-Dynamic Input Speed (lb-in) (Nm) (lb-in) (Nm) (rpm) HYDRAuLIC DRIvE (57.4 CID Motor) Pressure Flow Cable Size (in) Capacity (ft) Capacity (m)

Open the catalog to page 12

000 lb.ing Capacity Approximate weight: 2,500 lb Mechanical RUFNEK® Worm Gear Winches R^J130^W

Open the catalog to page 13

HANGER BEARINGS HB544 1-1/4” hanger bearing designed for use on models RN10W through RN30W. HB800 1-1/2” hanger bearing designed for use on models RN45W through RN130W. MECHANICAL DRIVI

Open the catalog to page 14

LEVER ASSEMBLY Allows remote mechanical operation of winch with ratchet and pawl lock. Includes levers, threaded rod, clevis, nuts, washers, cap screws and pins. AiR CONTROL KiTS Complete system to convert winch to air-shift configuration. Includes cylinders, tubing, fittings, clutch valve and metering valve for brake band. Winch Model HYDRAULIC DRIVE C Complete drive group ready to install. Includes pump, reservoir, filter and control valve. Winch Model RUFNEK® Worm Gear Accessories

Open the catalog to page 15

Basic Model Gear Type W-Worm Clutch Device M=Mechanical A=Air Motor Type 3. Single-Speed Geroler X. No Motor □rive Type H=Hydraulic M=Mechanical Gear Box Position (relating to truck] L=Left R=Right Cable Spooling 0=0ver Drum U=Under Drum - Input Shaft Location [relating to truck] F=Front R=Rear X=Does not apply Contact sales@team-twg.com for other options or assembly configurations. TWGQ& POVX/ER to Move the World™ A DOVEB) companyHave a Question? To speak with a Tulsa Winch technical representative or to order Tulsa Winch parts, call us at 918.298.8300 or visit our Web site at...

Open the catalog to page 16All Tulsa Winch catalogs and technical brochures

-

TULSA

6 Pages

-

RUFNEK PLANETARY WINCHES

12 Pages

-

Safer Operation by Design

2 Pages

-

Hydraulic Pump Drives Catalog

52 Pages

-

LINEMAN Catalog

18 Pages

-

Winch Power. Built to Order.

2 Pages

-

R7 Unimog

2 Pages

-

Gear products

2 Pages

-

Model 24

2 Pages

-

RN30W

1 Pages

-

RN20W

1 Pages

-

Model 18G

2 Pages

-

Model 12

2 Pages

-

Model 1060/1242

4 Pages

-

Model 1060

4 Pages

-

RN15W

1 Pages

-

RN10W

1 Pages

-

Model 938

2 Pages

-

RN130P

3 Pages

-

RN100P

3 Pages

-

RN80P

3 Pages

-

RN60P

3 Pages

-

RN45P

3 Pages

-

3541RL

1 Pages

-

Model 30P

2 Pages

-

Model 1500W

4 Pages

-

Model 1200W

4 Pages

-

Model 707W

4 Pages

-

Swing/Winch Drives

4 Pages

-

Speed Reducers

8 Pages

-

Model 800H

2 Pages

-

Model 506W

4 Pages

-

Planetary Reducer Series

1 Pages

Archived catalogs

-

Winch application manual

21 Pages