Catalog excerpts

HYDRAULIC PUMP DRIVES Mobile equipment hydraulic pump drives engineered for the construction, forestry, petroleum, marine and agricultural markets.

Open the catalog to page 1

Gear Products is a leading manufacturer of mechanical power transmission components for off-highway trucks, cranes and heavy equipment that serve the utility, petroleum, construction, agricultural, forestry, marine and mining industries. We distinguish ourselves by delivering customengineered products quickly — with the superior quality and long-lasting performance our customers have come to expect since 1957. Gear Products offers one of the largest product ranges of its kind anywhere. Our planetary and worm gear winches, swing drives, auger drives, slewing ring bearings, rotators,...

Open the catalog to page 2

TWG | Gear Products 11135 S James Ave, Jenks OK 74037-1731, USA | +1-918-298-8300 | www.team-twg.com

Open the catalog to page 3

IMPORTANT NOTICE Disregarding system torsional compatibility can cause damage to components in the drive train, resulting in a loss of mobility for which the hydraulic pump drive is intended. At a minimum, system torsional incompatibility will result in undesirable noise and vibration at low speeds. Gear Products, Inc. (GPI) recommends that a torsional vibration analysis of the pump drive/drive train system be performed on all new installations. Torsional vibration analysis can be made by the engine builder or by an independent consultant. CAUTION! Any user of enclosed gear drives should...

Open the catalog to page 4

HYDRAULIC PUMP DRIVE ENGINE MOUNTING RECOMMENDATIONS 1. Obtain from the engine manufacturer a torsional vibration and bending fatigue analysis. Torsional vibration on the HPD will be furnished by GPI upon request. 2. A three (3) point elastomer isolator mount is recom mended to prevent the engine and HPD from becoming a structural member of the equipment. For isolator selection and load analysis consult the isolator manufacurer. t 3. Contact your engine manuacturer for flywheel f housing bending moment data. A saddle mount bracket de igned to accomodate the bending s moment of the HPD...

Open the catalog to page 5

MODEL CODE FOR HYDRAULIC PUMP DRIVES D Pump Data A2 = SAE “A”, 2 Bolt B = SAE “B”, 2 or 4 Bolt BB = SAE “BB”, 2 or 4 Bolt C = SAE “C”, 2 or 4 Bolt CC = SAE “CC”, 2 or 4 Bolt D4 = SAE “D”, 2 or 4 Bolt E4 = SAE “E”, 4 Bolt Input C - Clutch G - Gear P - Plate R - Rubber Block S - Shaft T - Torsional Coupling Gear Ratio E = Even D = Down U = Up Output 0 = 1 Pump, Direct 1 = 1 Pump, Geared 2 = 2 Pump, Geared 3 = 3 Pump, Geared 4 = 4 Pump, Geared 5 = 5 Pump, Geared Refer to selected models for available gear ratios Drive Plate/Clutch Nominal Size (per SAE J620) for Plate Diameter SAE Housing...

Open the catalog to page 6

APPLICATION & INSTALLATION INFORMATION Company Name _ _Date _ _Date _ Start-Up Date_ _Required Date Data Supplied By Title_ Data Received ByTitle_ Annual Production Requiring HPDs_ Prototype Required Yes □ No □ Number Type of Equipment Industrial EH Marine EH Mobile EH Engine Type and Manufacturer Electric Motor Other _ Model No. Horsepower@ Full Load Gov. rpm HPD Location Front EH Rear EH Remote I I SAE Flywheel Housing Size (J620C) SAE Flywheel Size (SAE J617) Flywheel Offset (“G” Dimension SAE J617) _ Pilot Bearing Size HPD Input Drive Clutch SizePlate Size_ Shaft Type_ Rubber...

Open the catalog to page 7

Ratings may vary depending on duty cycle load and environment. Refer to SAE J744c information on page 43 or contact your pump supplier. Gear Products Single Pump Direct Drives are available in three configurations. Specifications are subject to change without notice. features • Drive Plate Pilots off O.D. of Flywheel Instead of Pilot Bore • Hubs are Secured to the Flex Plate with Lock tited Capscrews Rather than Cold Rivets • Heavy Duty Drive Plate standard dpoi TWG | Gear Products 11135 S James Ave, Jenks OK 74037-1731, USA | +1-918-298-8300 | www.team-twg.com

Open the catalog to page 8

SINGLE DIRECT PLATE DRIVES TWG | Gear Products 11135 S James Ave, Jenks OK 74037-1731, USA | +1-918-298-8300 | www.team-twg.com 7

Open the catalog to page 9

TWG | Gear Products 11135 S James Ave, Jenks OK 74037-1731, USA | +1-918-298-8300 | www.team-twg.com

Open the catalog to page 10

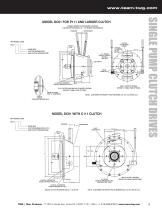

MODEL DC01 WITH Cl 11 CLUTCH HPD MODEL CODE DC01- * - * - * SINGLE PUMP CLUTCH DRIVES TWG | Gear Products 11135 S James Ave, Jenks OK 74037-1731, USA | + 1-918-298-8300 | www.team-twg.com 9

Open the catalog to page 11

specifications Input Torque: 934.3 N-m (max) Kilowatts: 244.6 (max) Maximum Speed: See Ratio Chart Approximate Weight: 79.38 kg (gearbox only) Oil Capacity Approximately 1.42 l (may vary due to output orientation and gear ratio) (Ratings Based on 1:1 Ratio, 2500 rpm and 2000 hrs B10 Life) Specifications are subject to change without notice. features • Dipstick Included for Maintaining Proper Fluid Level I* Rotation Opposite Input • Full Fillet Gears for Optimum Strength • Large Diameter Ball Bearings for Higher Speeds and Longer Life • Heavy Duty Drive Plate • Output Options: Spline, Keyed,...

Open the catalog to page 12

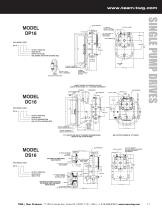

OUTPUT POSITION GEAR RATIO DRIVE PLATE SIZE SAE ENGINE ADAPTER HOUSING SIZE EQUALLY SPACED COUPLING TO PUMP FACE HANDLE SHOWN IN STANDARD LOCATION MODEL DC16 HPD MODEL CODE GEAR RATIO CLUTCH DESIGNATION SAE CLUTCH HOUSING SIZE MODEL DS16 HPD MODEL CODE OUTPUT POSITION GEAR RATIO INPUT TYPE BOTH SIDES CAN BE REPOSITIONED IN 7 1/2 DEGREE INCREMENTS CLUTCH ADJUSTMENT SINGLE PUMP DRIVES j CLUTCH P114 CLUTCH AND SAE #1 FLYWHEEL HOUSING SHOWN SAE C OUTPUT SHOWN AT 12 O’CLOCK REFER TO TABLE FOR OPTIONS OF DIPSTICK OIL FILL & VENT 365.1 mm VERTICAL CLEARANCE CLEARANCE REQUIRED OPTIONAL SPLINED...

Open the catalog to page 13

specifications Input Torque: 2657.8 N-m (max) Kilowatts: 695.7 (max) Maximum Speed: See Ratio Chart Approximate Weight: 158.76 kg (gearbox only) Oil Capacity Approximately 4.73 l (may vary due to output orientation and gear ratio) (Ratings Based on 1:1 Ratio, 2500 rpm and 2000 hrs B10 Life) Specifications are subject to change without notice. features • Dipstick Included for Maintaining Proper Fluid Level I* Rotation Opposite Input • Full Fillet Gears for Optimum Strength • Large Diameter Ball Bearings for Higher Speeds and Longer Life • Heavy Duty Drive Plate • Output Options: Spline,...

Open the catalog to page 14All Tulsa Winch catalogs and technical brochures

-

TULSA

6 Pages

-

RUFNEK PLANETARY WINCHES

12 Pages

-

RUFNEK Worm Gear Catalog

16 Pages

-

Safer Operation by Design

2 Pages

-

LINEMAN Catalog

18 Pages

-

Winch Power. Built to Order.

2 Pages

-

R7 Unimog

2 Pages

-

Gear products

2 Pages

-

Model 24

2 Pages

-

RN30W

1 Pages

-

RN20W

1 Pages

-

Model 18G

2 Pages

-

Model 12

2 Pages

-

Model 1060/1242

4 Pages

-

Model 1060

4 Pages

-

RN15W

1 Pages

-

RN10W

1 Pages

-

Model 938

2 Pages

-

RN130P

3 Pages

-

RN100P

3 Pages

-

RN80P

3 Pages

-

RN60P

3 Pages

-

RN45P

3 Pages

-

3541RL

1 Pages

-

Model 30P

2 Pages

-

Model 1500W

4 Pages

-

Model 1200W

4 Pages

-

Model 707W

4 Pages

-

Swing/Winch Drives

4 Pages

-

Speed Reducers

8 Pages

-

Model 800H

2 Pages

-

Model 506W

4 Pages

-

Planetary Reducer Series

1 Pages

Archived catalogs

-

Winch application manual

21 Pages