Catalog excerpts

AFS Pallet accumulating conveyor system System APM AFS - APM Conveying System 1

Open the catalog to page 1

AFS Accumulationg Conveyor Overview Centre profile for integration of the drive chain Drive station Robust side profiles for a stable self-supporting construction with integrated pallet guide Reversing station Pallet in modular aluminium design AFS - APM Conveying System 2

Open the catalog to page 2

Construction of pallet Plastic roller with concave running surface Dual friction sprocket Steel tube guide rail flush-mounted into the profile Modular pallet construction in aluminium screwfitted design AFS - APM Conveying System 3

Open the catalog to page 3

Pallet transportation with positive fit during directional change • Through spring-supported pins, the pallet is conveyed by the driving sprocket and changes direction with positive fit • Situation of pallet shortly before it engages into the driving sprocket AFS - APM Conveying System 4

Open the catalog to page 4

Detail: Isolation of pallets Synchronised rockers with one stopping and one isolating roller each AFS - APM Conveying System 5

Open the catalog to page 5

Detail: Geared motor with overload switch • If the predefined load torque is exceeded, e.g. due to pallet crash etc., the drive unit is switched off Overload switch AFS - APM Conveying System 6

Open the catalog to page 6

Realisation of special lengths > 20 m • Connection of individual segments through synchronous operation AFS - APM Conveying System 7

Open the catalog to page 7

Option: Automated component unloading / Transmittor AFS - APM Conveying System 8

Open the catalog to page 8

Pallet load design guidelines Y1 Y2 PALLET WIDTH [ mm ] 660±0.05 370±0.05 265 265 X2 180±0.2 180±0.2 A 150x300 400 X1 150x500 700 Y2 X2 Y1 (x6)M8 (x6)M8 B (x2)Ø8H7 (x2)Ø8H7 1.2 - Weight: workpiece + workpiece carrier As to conveyance, we have to consider the following graphic illustrations for the distribution of the centre of gravity in relation to the sum of the weights (P1+P2): 100 Kg 100 Kg 50 Kg 50 Kg 90 Kg 90 Kg 30 Kg 30 Kg 75 Kg 75 Kg 10 Kg 10 Kg Mass centre of gravity of the empty tool (P1) Centre of the workpiece to be transported (P2) AFS - APM Conveying System 9

Open the catalog to page 9

Application example 1 Horizontal accumulating conveyor AFS - APM Conveying System 10

Open the catalog to page 10

Application example 2 90° accumulating conveyor AFS - APM Conveying System 11

Open the catalog to page 11

Application example 3 90° accumulating conveyor AFS - APM Conveying System 12

Open the catalog to page 12

Application example 4 90° accumulating conveyor “around the bend“ AFS - APM Conveying System 13

Open the catalog to page 13All TÜNKERS catalogs and technical brochures

-

Tünkers Multiflex Console

1 Pages

-

CLAMPING

3 Pages

-

Positioning

3 Pages

-

GRIPPING

3 Pages

-

FORMING

3 Pages

-

DOSING

2 Pages

-

WELDING

3 Pages

-

CONVEYING

3 Pages

-

TURNING

3 Pages

-

TRANSPORTING

3 Pages

-

Hydraulic Cylinder HYZ...

1 Pages

-

Lift Unit MZVD 40

1 Pages

-

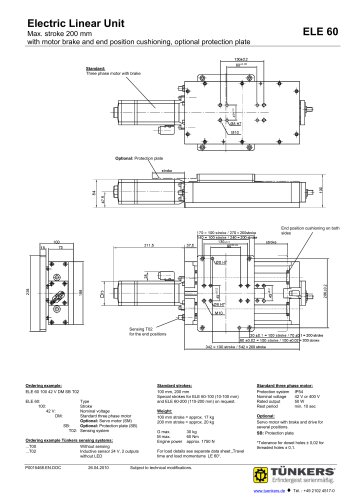

Electric Linear Unit ELE 60

1 Pages

-

TÜNKERS Imagepresentation

132 Pages

-

Hole and punching units

44 Pages

-

Manual clamps - Standard range

10 Pages