Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

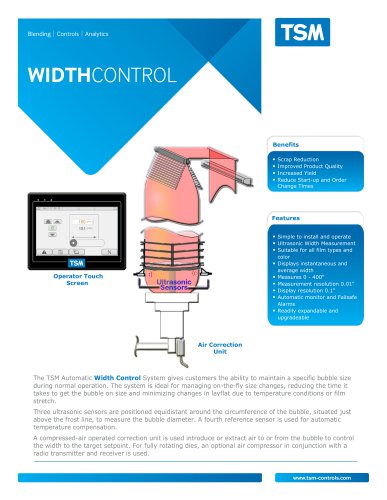

Blending | Controls | Analytics r ; \Benefits • Scrap Reduction • Improved Product Quality • Increased Yield • Reduce Start-up and Order Change Times • Simple to install and operate • Ultrasonic Width Measurement • Suitable for all film types and color • Displays instantaneous and average width • Automatic monitor and Failsafe Alarms • Readily expandable and upgradeable The TSM Automatic Width Control System gives customers the ability to maintain a specific bubble size during normal operation. The system is ideal for managing on-the-fly size changes, reducing the time it takes to get the bubble on size and minimizing changes in layflat due to temperature conditions or film stretch. Three ultrasonic sensors are positioned equidistant around the circumference of the bubble, situated just above the frost line, to measure the bubble diameter. A fourth reference sensor is used for automatic temperature compensation. A compressed-air operated correction unit is used introduce or extract air to or from the bubble to control the width to the target setpoint. For fully rotating dies, an optional air compressor in conjunction with a radio transmitter and receiver is used.

Open the catalog to page 1

WIDTHCONTROL OPTIONAL COMMUNICATIONS PROTOCOLS • • • Ethernet IP (Allen Bradley) ModBus TCP ProfiNet FURTHER OPTIONS Remote width readout module Radio control compressor unit for fully rotating dies Ultrasonic Sensor Connections USMUX Air Correction Unit for non IBC Lines Operator Touch Screen European Office North America Regional Offices Asia-Pacific Regional Office China Regional Office TSM Ard Easmuinn, Dundalk, Co. Louth, Ireland. TSM Inc. 1505 Johnson Ferry Road Marietta, GA 30062, USA. TSM Taiwan Siangshang Street Taichung City, Taiwan, TSM China Room 2423, IPC Center, No. 983, East...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

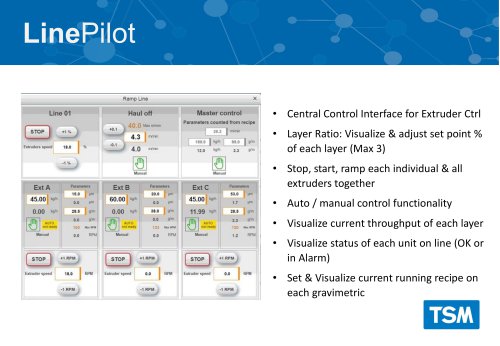

LinePilot

3 Pages

-

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

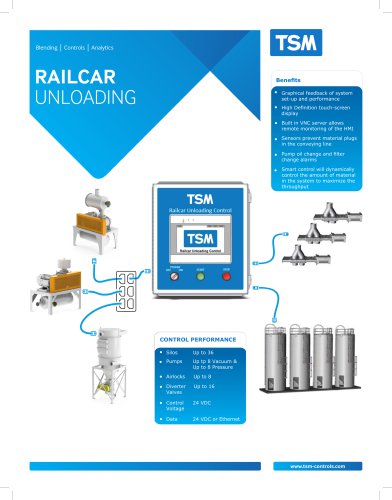

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

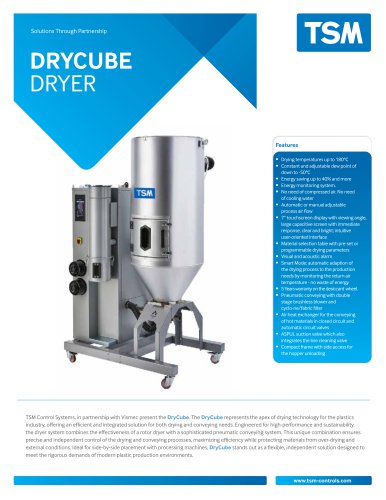

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

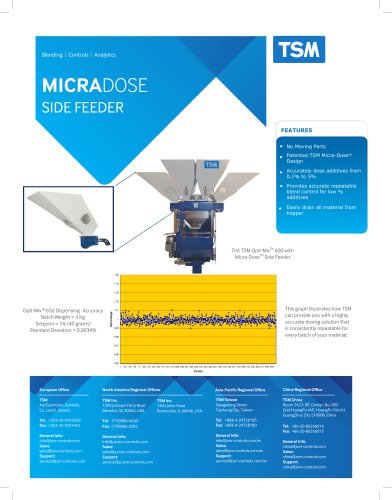

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

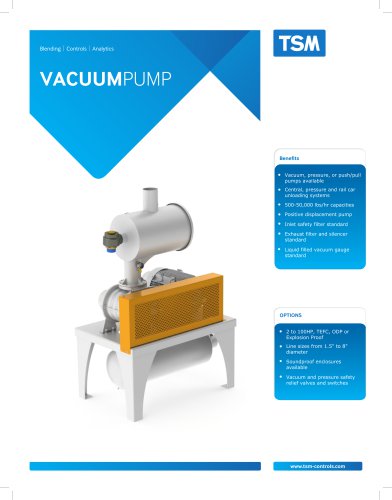

Vacuum Pump

1 Pages

-

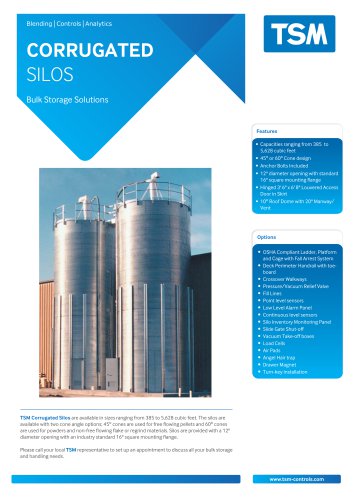

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages