Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

Features • Carbon Steel Construction • Tangential Material Inlet provides cyclonic air/material separation • No Motor so no Brush Wear • Economical: Uses approximately 3 CFM of compressed air per 100 Ibs/hr of material conveyed. • Efficient: conveys pellets with a bulk density of up to 45 Lb/cuft • Dust filter built into lid • Fully Automatic: Proximity sensor will start and stop the conveying of material • Includes pick-up wand with 10' of flex hose User Interface • Silent operation. • Quick installation with no protruding parts into the blender reservoir hopper • 6 mounting bolts provides adjustable orientation of the hopper in 60° increments • Easy dismantling with quick release band clamp for easy access of the filter for cleaning • Filter can be Replaced in Seconds without Tools As material loading is an integral part of every production process, minimal disruption of material flow with complete control is essential. TSM offers an economical, reliable and user friendly Venturi Mini-Loader to serve your additive material handling needs. Our stand alone Mini-Loader provides fast and accurate materials handling with minimal effort.

Open the catalog to page 1

Specialists in Gravimetric Blending & Controls Blending│Controls│Analytics Capacity (lt/cuft) C:\TSMControls\Engineering\Design C:\TSMControls\Engineering\Design Library\Purchased\Receivers\Tou Library\Purchased\Receivers\Tou Mou Mou Loaders\ Loaders\ 11 Capacity (lt/cuft) Weight (kg/lbs) Body Diameter 'B' (mm/in) Flange Diameter ‘C’ (mm/in) Pipe Adaptors (mm/ins) Weight (kg/lbs) Throughput (kg/hr / lbs/hr) Drawing Drawing Issued Issued DESCRIPTION DESCRIPTION DATE DATE APPROVED APPROVED REVISIONS REVISIONS TITLE: TITLE: European Office North America Regional Offices TSMEuropean Office Ard...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

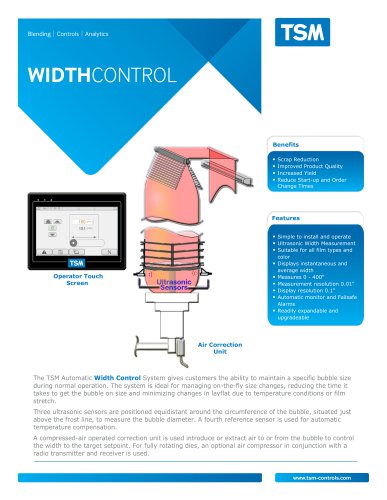

Width Control

2 Pages

-

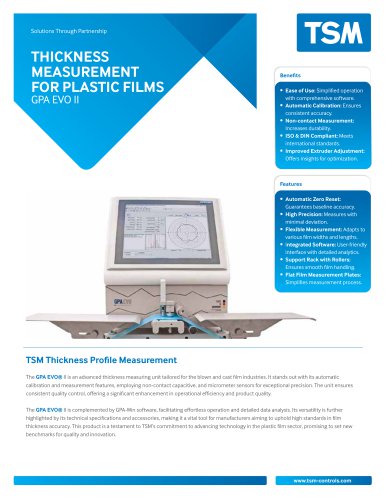

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

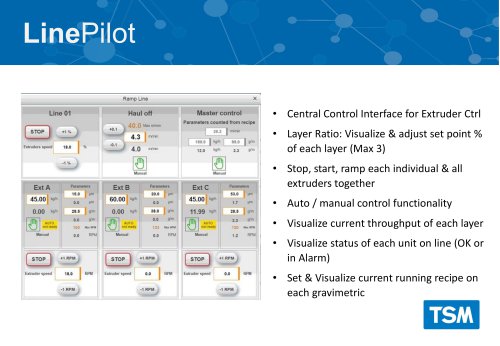

LinePilot

3 Pages

-

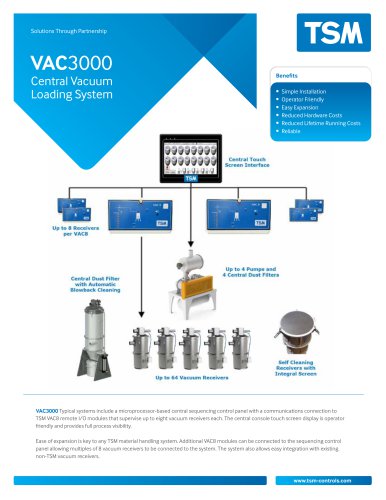

Vacuum Receiver

2 Pages

-

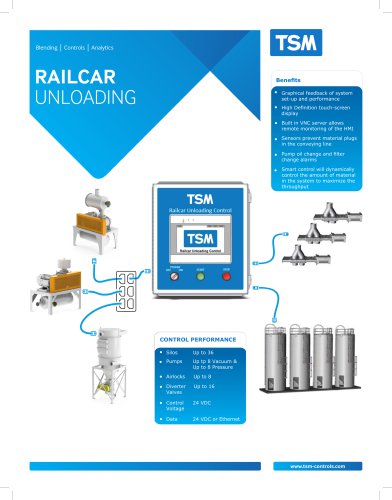

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

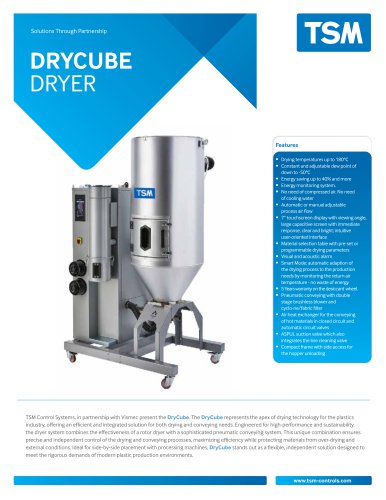

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

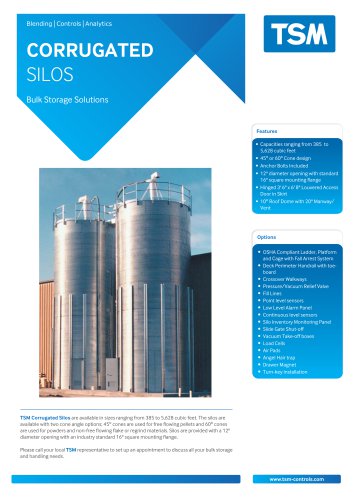

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

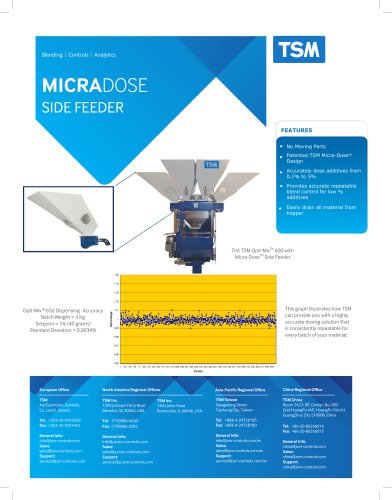

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

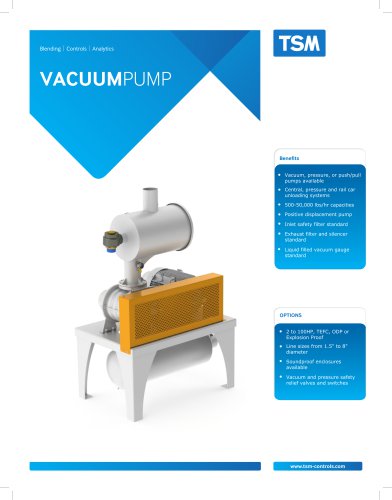

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages