Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

Solutions Through Partnership As material loading is an integral part of every production process, minimal disruption of material flow with complete control is essential. TSM offers a range of reliable and user-friendly Vacuum Receivers to serve your material handling needs up to 115 ltrs /4cuft. VACUUMRECEIVERSFeatures • Integral Vacuum Sequencing Valve on the Lid of the Receiver. • Easily Removable Lid for Access to Screen Filter for cleaning. • Stainless Steel Contact Surfaces • Reliable Material Flow • Quick Release Mechanisms allow Effortless Dismantling • Interchangeable Line Size Adapters • Separate On/Off Switch • Inspection Door • Modular Construction for Maximum Flexibility Benefits • Easy installation: - No Protruding Parts therefore no Intrusion into Blender Reservoir - Fully Directional Mounting Flange makes Installation Quick and Simple • Effortless dismantling: - Quick Release Inspection Mechanism for Easy Access - Easy Dismantling for Accessing the Vacuum Receiver without Tools • Easy Cleaning: - Screen Filter can be Cleaned and Replaced in Seconds without Tools • Status Indication: - Power, demand and filling indicators on the control box. • Stainless Steel Vacuum Manifolds • Anti-Static flex Tubing • Pick-up wands • Heavy Duty Vacuum Breaker Valve

Open the catalog to page 1

Solutions Through Partnership * More Line Size adapter options available on request European Office (Headquarters) TSMNorth America Regional Office TSM Inc. Asia-Pacific Regional Office China Regional Office TSM Control Systems, Finnabair Industrial Estate, Dundalk, Co. Louth, General: info@tsm-controls.com Sales: sales@tsm-controls.com Support: service@tsm-controls.com 1505 Johnson Ferry Road, General: info@us.tsm-controls.com Sales: sales@us.tsm-controls.com Support: service@us.tsm-controls.com No.13 Siangshang 1st Street, West District, General: info@tsm-controls.com.tw Sales:...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

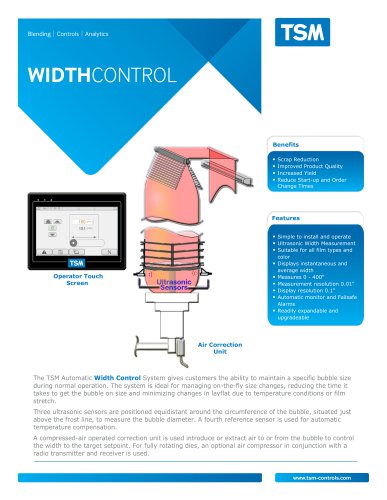

Width Control

2 Pages

-

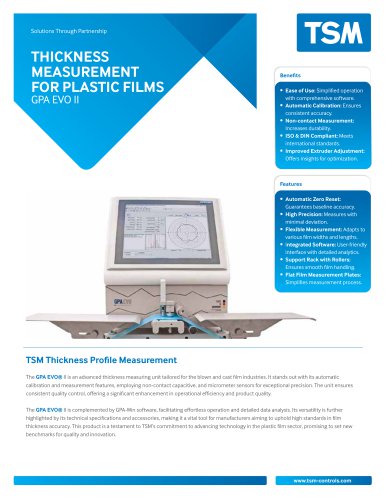

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

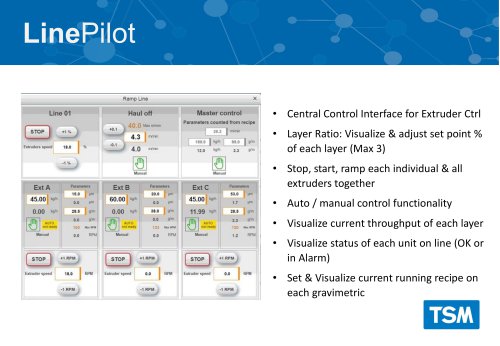

LinePilot

3 Pages

-

Venturi Mini Loader

2 Pages

-

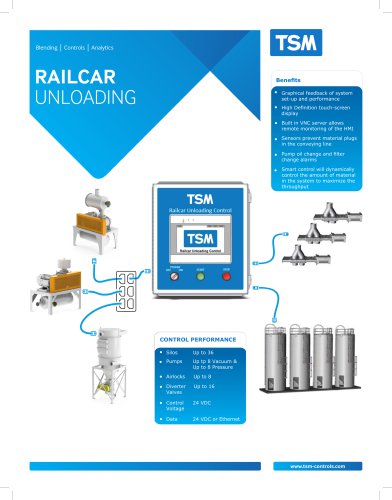

Railcar Adapter and Filter

1 Pages

-

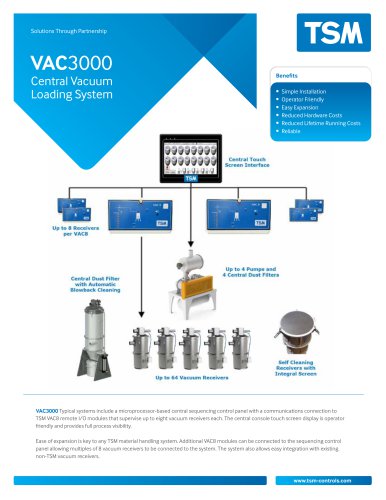

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

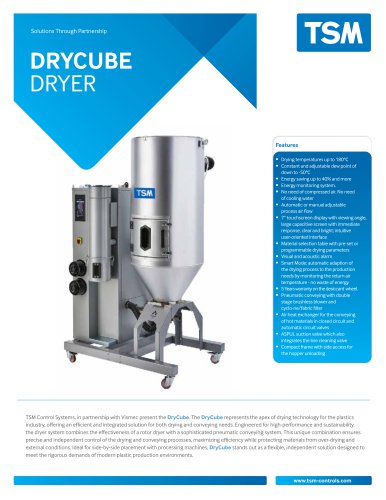

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

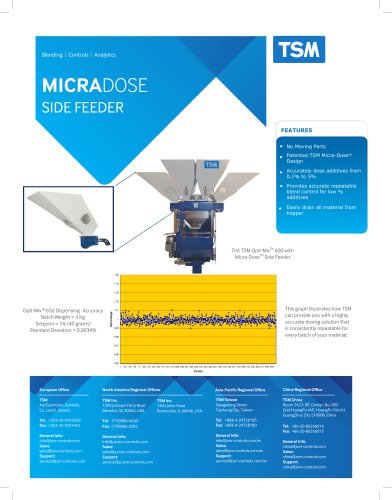

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

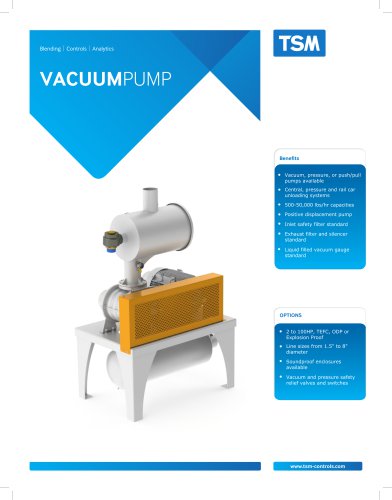

Vacuum Pump

1 Pages

-

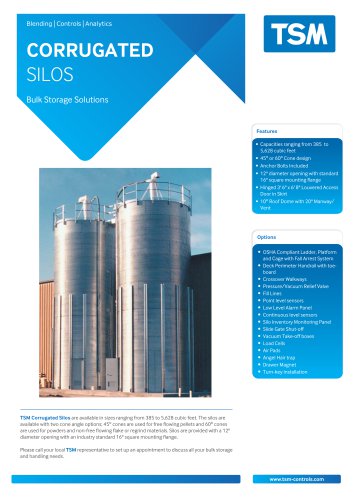

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages