Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

An economical concept, vital for a profit conscious customer, the TSM thickness profiler will help film producers increase productivity and improve quality while reducing scrap. The system is used for on-line measurement of the thickness profile in blown / film extrusion line installations. > Economical concept to increase productivity while reducing scrap, saving resin and improving product quality Օ No contact with film, therefore no scratching On-spec film thickness improves print consistency Օ Measurement is only made when film has cooled to ambient temperature - so the system measures exactly what the customer is paying for On-spec film thickness increases customer and end user satisfaction > Օ This device measures the film at the edge of lay-flat film The film glides through the spacing between two electrodes without making contact Օ The blown film thickness is determined by measuring the capacitive changes that occur in the space between the electrodes as the film glides through An electronic signal corresponding to the capacitive changes is transmitted to the process control as a thickness profile Օ This profile can be correlated to the die bolts of the extruder by taking into account the rotation and zero position of the blown film line To cope with fluctuating film edge position, the option of an automatic edge positioning device is available to ensure measurement consistency. It also allows automatic reset to zero at regular intervals >

Open the catalog to page 1

New Radiation-free capacitance measurement principle Օ No contact necessary at all with the film High resolution due to small measured area Օ An easy to use operator control console with easy to use operator friendly software Real time read out of film thickness profile available at a glance - allowing timely action to ensure product consistency Օ Average high/low and standard deviation information also available from the software High, low and average alarm limits with option to print a profile plot automatically if an alarm is exceeded > Polar & Trend Profile Plot s Օ Option of Auto-reset...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

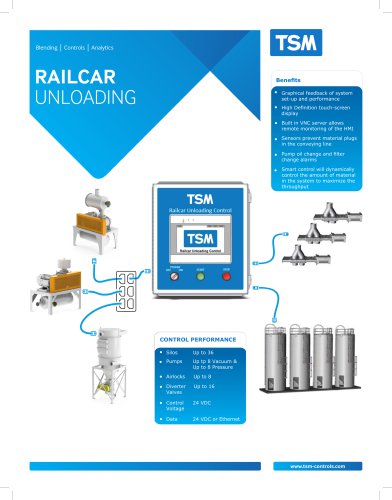

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

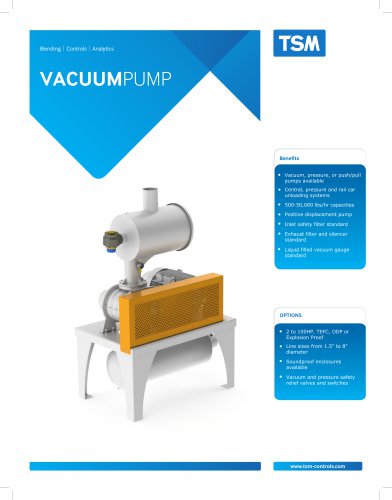

Lubricated Vacuum Pump

1 Pages

-

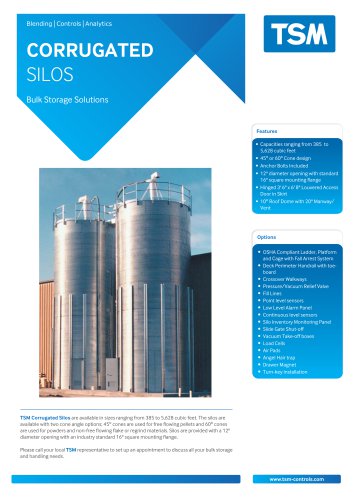

Bulk Material Silos

2 Pages

-

BOXUNLOADER

2 Pages

-

AUTOMATICDEBAGGINGGSYSTEM

6 Pages

-

OPTIPOW SERIES

2 Pages

-

OPTIFLAKE

1 Pages

-

OPTIFEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTIBLEND

2 Pages

-

OPTIX

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

Archived catalogs

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages