Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

TSM Material Drying Portfolio

Open the catalog to page 1

DESIGN BASIS: Drying solutions for multiple materials Presentation of multiple solution suitable to dry different kinds of granules in accordance with customer specific needs. Before presenting our range of, it’s useful to analyse 2 focal points revolving around plastic raw materials: Types of granules and moisture. Granules types and sizes: Granules: dimension range: from 200 mm to few mm (5-6 mm) Micro-spheres (or micro-granules):200-500 mm Can be conveyed by loaders fitted with cartridge filters with filtration degree of 20 mm Powder: dimensions less than 20 mm (“impalpable”) Powder...

Open the catalog to page 2

HD – HOT AIR DRYERS These dryers consist of a fan which takes ambient air into a heating chamber to heat it up to a set temperature. The hot process air is blown into a drying hopper, from the bottom to the top, passing by the granules thus heating them up and removing the moisture by stripping it off from the granule surface and evaporating in the hot airstream. The return air is filtered by a cartridge filter and then partially or totally exhausted in atmosphere by a by-pass valve, thus optimizing drying cycle and improving energy saving. Characteristics: Temperature range: 70 ÷ 150 °C...

Open the catalog to page 3

Customizable solutions:

Open the catalog to page 4

MD – MOLECULAR SIEVES DRYERS Able to handle even the most modern high-tech materials with a dedicated air flow and temperature control, that together with RCE function and dedicated thick insulated hoppers, create the perfect drying environment. These dryers represent an optimal solution from the smallest throughput up the higher ones, able to cope with the most demanding environment. MD/MDC series is the generation of compact twin-beads desiccant dryers with modern design and extremely interesting technical performances and energy saving concepts. MDS series, designed and manufactured to...

Open the catalog to page 5

Customizable solutions:

Open the catalog to page 6

MOLECULAR SIEVES “13X” made of synthetic crystalline aluminum silicates With important qualities of an adsorbent (desiccant), High “adsorption” capacity and possibility to be regenerated and used again. Molecular sieves are contained in cylindrical towers to perform the best airflow with reduced pressure drops with the most efficient air speed to transfer the moisture from air to the desiccant. Towers in stainless steel in order to avoid rust formation and reflect part of the heat produced internally during regeneration. Together with the outer insulation there is considerably reduction of...

Open the catalog to page 7

AD / ADK – COMPRESSED AIR DRYERS AD series designed to be machine mounted or with trolley for small medium throughputs. On its basic version hoppers have standard performances with dew point of -20°C. Utilizing the “Extra Drying Kit”, version ADK, the performances rise up to -50°C dew point. The electronic control panel allows easy programming via the internal data-base of main materials, with the possibility of free implementation of the data by the operator. Besides It also allows modulation of the compressed air flow as a function of; the hourly capacity and type of material which, in...

Open the catalog to page 8

THE USE OF COMPRESSED AIR The idea to use compressed air for drying, comes from the fact that compressed air is present in each plastic processing factory and it is also already partially dried. Compressed air when expanded at atmospheric pressure results having a lower dew point than when compressed. This effect can be used to dry polymers. In the majority of industrial compressed air systems It has values of about +5°C with average pressure of 7 bar. Nevertheless, when compressed air expands from 7 bar to atmospheric pressure, the dew point results of -21°C Improve dew point: This element...

Open the catalog to page 9

WD – ROTOR HONEYCOMB DRYERS This series is based on the use of a rotating drum impregnated with a mixture of molecular sieves, granting a stable dew point of -45°C. This dryer, with a solid and proper air circuitry and the new Triflux air heat-exchanger permits to recover large part of the heat by reducing energy consumption of over than 30% compared to conventional drying system. In addition, a WD doesn’t require periodic maintenance to change sieves nor needs compressed air. It may be possible however, to integrate water exchanger for process temperature over 140°C. Characteristics:...

Open the catalog to page 10

Customizable solutions

Open the catalog to page 11

Shape: This solution is called honeycomb rotor dryer because the structure of the sieves looks like a bee hive. The shape of this impregnated substrate in the rotor allows free airflow with reduced pressure drops. Pure crystalline desiccant is embedded in a woven substrate, then permanently bonded onto the substrate which is consequently formed into a tightly wound wheel. Continuous process: The new matrix of silica gel and molecular sieves on desiccant wheels is key in delivering more and more efficient and reliable systems. The honeycomb rotor allows to have a continuous process phase...

Open the catalog to page 12All TSM Control Systems catalogs and technical brochures

-

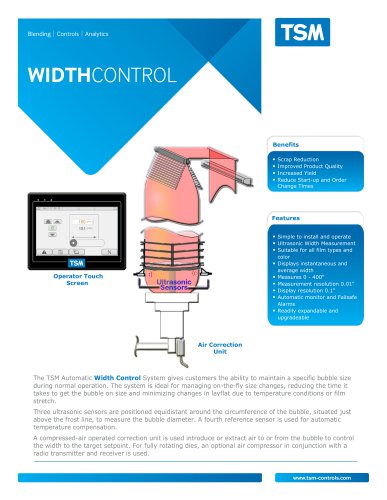

Width Control

2 Pages

-

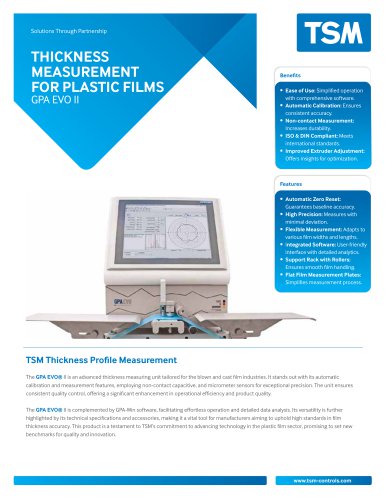

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

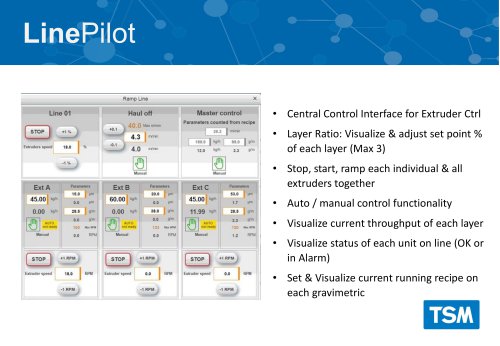

LinePilot

3 Pages

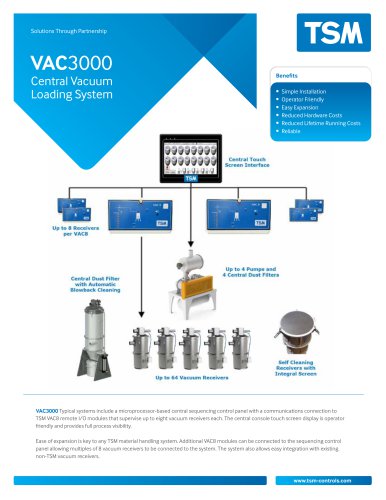

-

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

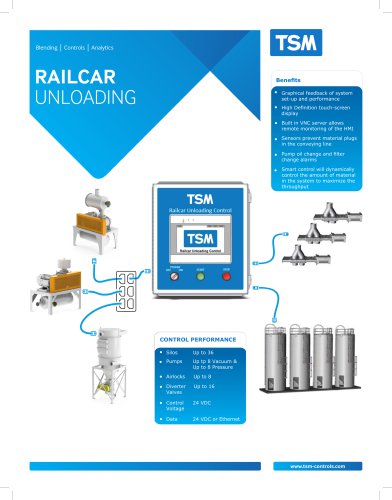

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

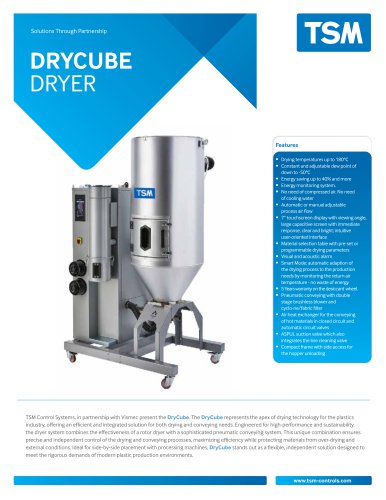

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

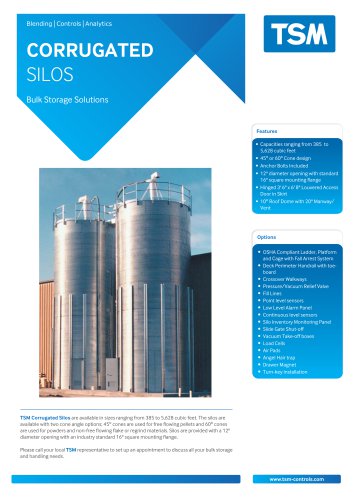

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

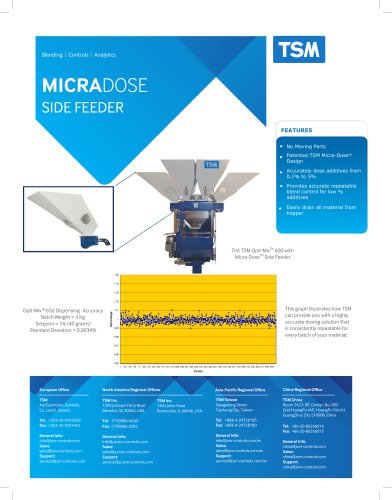

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

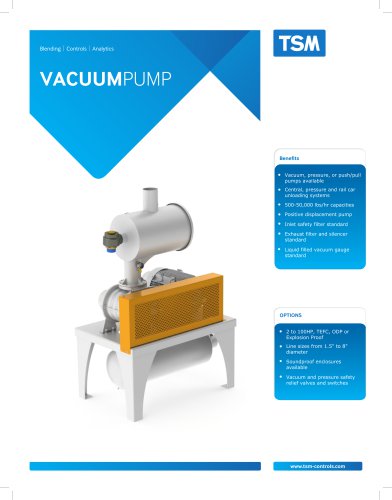

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages