Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

To enable instantaneous changes in throughput, the TSM Gravimetric Blenders continuously monitor and control extruder throughput (lb/hr or kg/hr) and can also be used to optimise yield (weight per length control). The system will also provide Roll, Order and Shift summaries by component, allowing precise calculation of material costs, profit margins per customer order etc. Operation: > Extrusion control means tighter tolerances, allowing down-gauging and increased line speeds. Higher yields of 2 - 3% are readily available. Extrusion control allows you to run at minimum thickness measurement values while maximizing consistency. - Kilograms per Hour - Grams per Meter - Grams per Meter square - Microns - Roll Weight / Roll Length As part of job recipe entry, the defined extrusion / haul-off control set points are entered in the remote operator panel. If a Co-Extrusion line is in use, the individual layer percentage information is entered on the TSM CP2000 for automatic multi- layer control. The TSM control monitors the line speed and extruder output to guarantee on-spec consistent output quality, thus reducing waste considerably. > - Mounted directly on the extruder - Eliminates height problems and the expense of a secondary weigh hopper - The system employs adaptive control and monitoring software that controls the extruder screw speed or line speed - The unique TSM algorithms provide automatic compensation for bulk density variations (including regrind) allowing material to be extruded at the lowest set points - The system can respond instantly to changes in haul-off speed or execute new set point entrys via a proprietary TSM ґstart up software routine >

Open the catalog to page 1

TSM offer a dedicated web server and Ethernet interface as part of each blender. This option allows access to each System via a factory network (Intranet) or the Internet. Thus, blenders can be monitored, analyzed and problems diagnosed from anywhere on the globe (SERVICE) or from any PC connected to the factory Intranet (PRODUCTION). > Օ Tel: +353-42 9335560 Fax: +353-42-9334422 Օ Tel: +1-770-8866630 Fax: +1-770-8862395 Օ E-mail: info@tsm-controls.com Website: www.tsmcontrols.com > TSM Reserve the right to change product specifications at any time without prior notice size="-1">

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

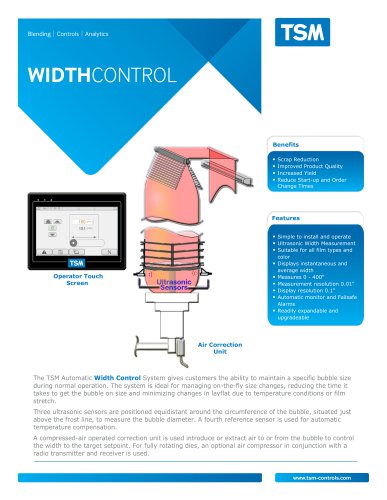

Width Control

2 Pages

-

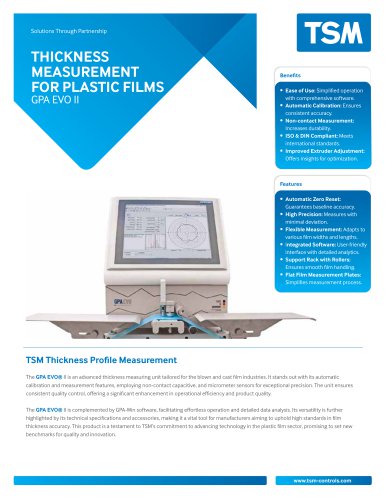

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

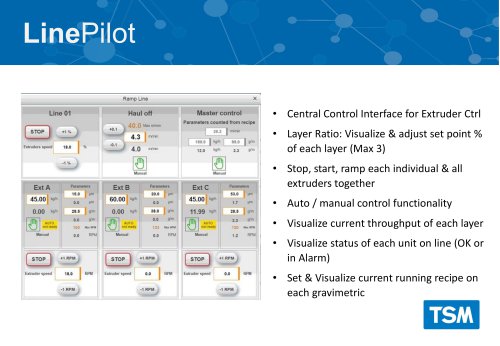

LinePilot

3 Pages

-

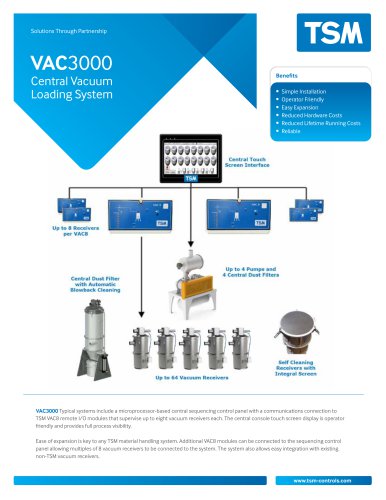

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

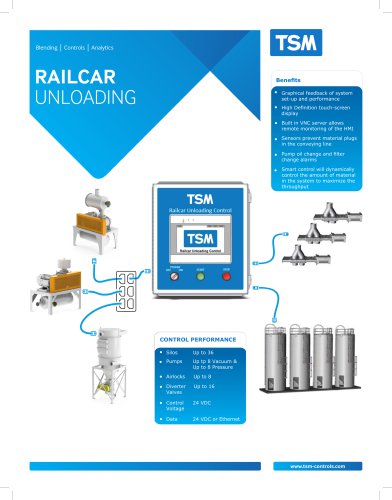

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

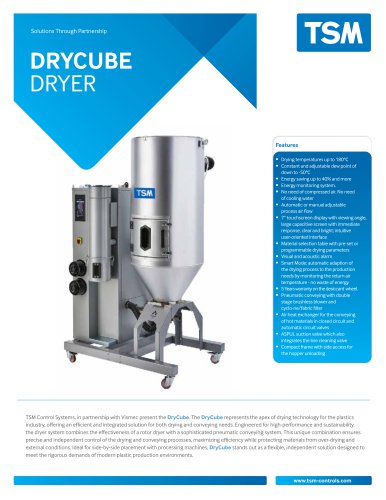

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

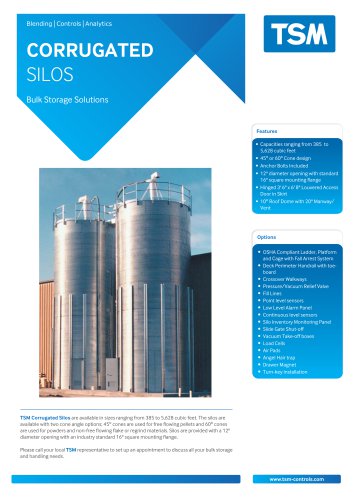

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

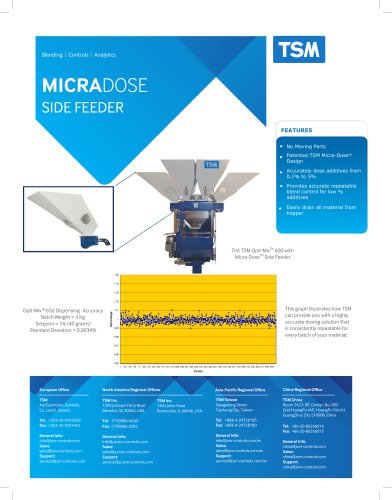

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

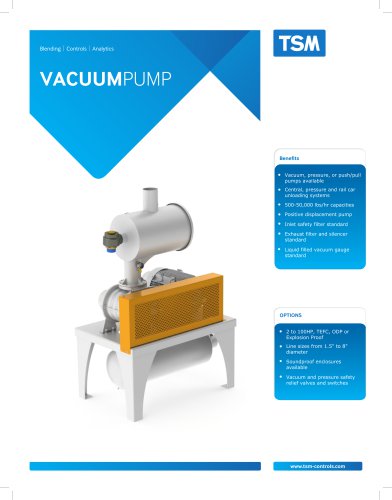

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages