Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

TSM Control Systems has been manufacturing batch weighing systems since 1985. The Sigmabatch series of gravimetric batch blenders are designed for optimum performance when mounted directly on the machine or for off-line use. They provide accurate blend ratios and batch homogeneity with a consistency superior to competitive blenders, based on the TSM patented mixing technique (see below.) > TSM50 (0.5Kg): Up to 50 kg/hr TSM150 (1kg): Up to 150 kg/hr TSM250 F (4kg) Up to 250 kg/hr TSM350 (2kg): Up to 350 kg/hr TSM650 (4kg): Up to 650 kg/hr TSM1000 D (7kg) Up to 1,000 kg/hr TSM1000 (7kg): Up to 1,000 kg/hr TSM1500 (12kg): Up to 1,500 kg/hr TSM3000 (24kg): Up to 3,000 kg/hr > The TSM Blender Range ٕ Guaranteed rapid return on investment Dosing Accuracy as low as +/- 0.1% of setpoint Օ Remote operator console (Up to 100m cable) Quick cleaning features for rapid job changes Օ Capable of a batch to batch consistency of +/- 0.02%. Primary Vibration Control Ֆ Vibration / Shock Resistant > For perfect mixing, every batch - every time It must be TSM! The TSM SigmaBatch range of blenders are compact with a low height profile. They are RUGGEDLY CONSTRUCTED of heavy gauge steel to withstand the most rigorous of operating conditions. The load cell is overload protected and guarded from physical damage >

Open the catalog to page 1

An easy-to-service control module, as shown, contains the blender electronics. The control panel is extremely user friendly and provides intuitive text prompts. Up to 60 pre-programmed recipes are instantly accessible, enabling rapid "on-the-fly" order changes. The recipe select and order queue features allow a new job to be down-loaded instantly, including blend percentages, thickness, throughputs or job sizes. As the job progresses, the operator can view SetӔ and ActualӔ blend recipes, material weights and Kg/h throughput, Weight per length or Micron thickness, and alarm incidents which...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

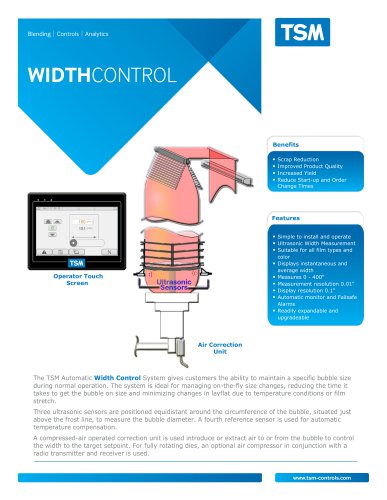

Width Control

2 Pages

-

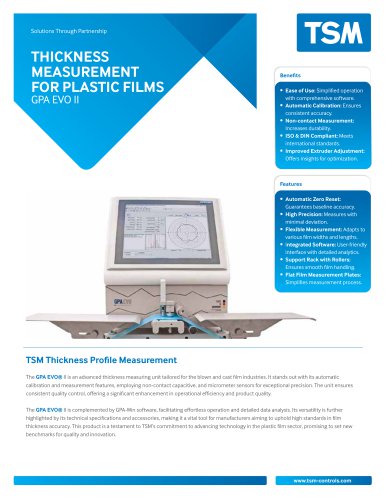

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

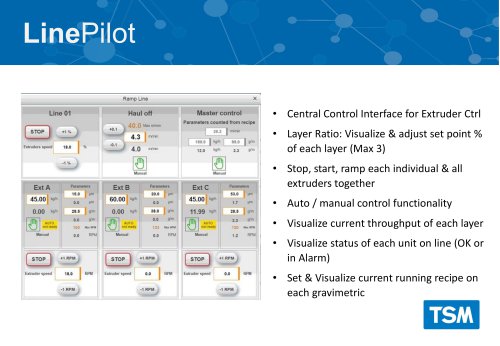

LinePilot

3 Pages

-

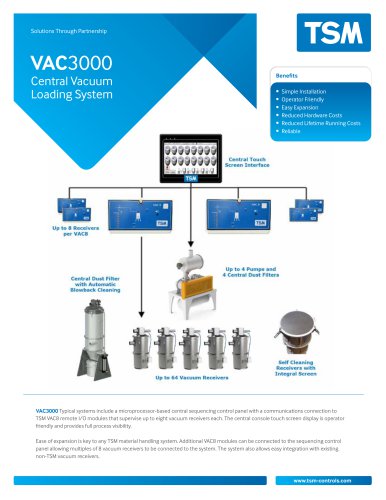

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

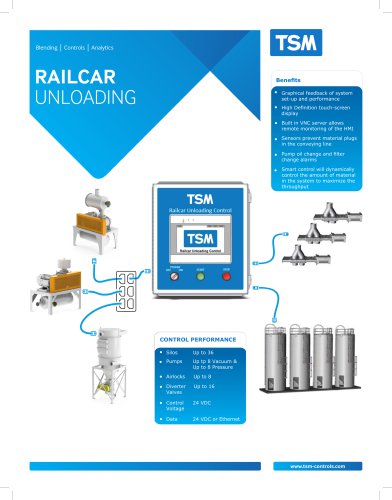

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

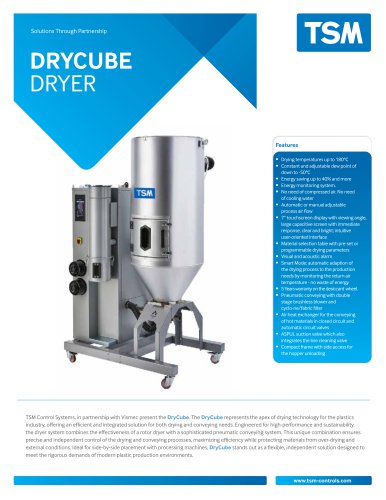

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

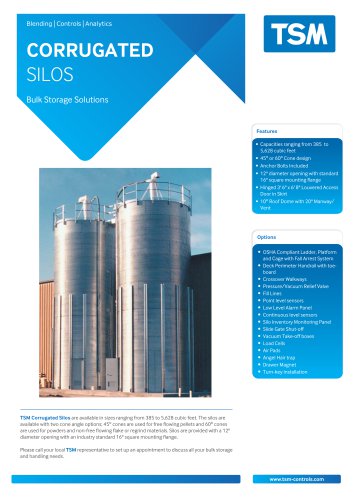

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

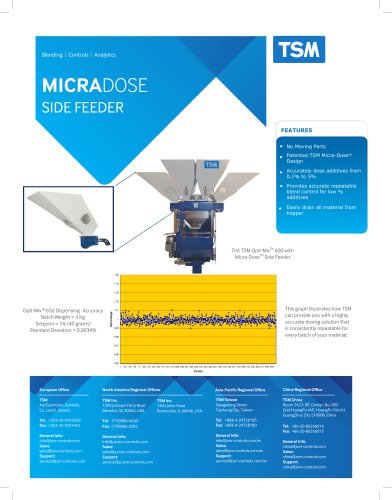

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

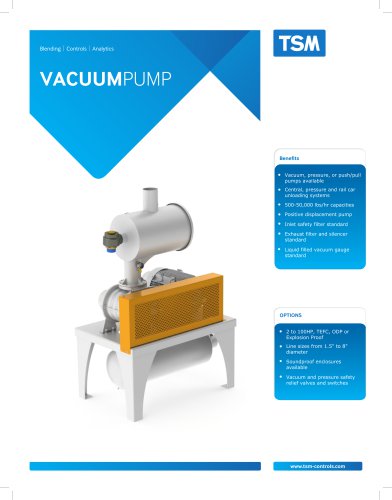

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages