Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

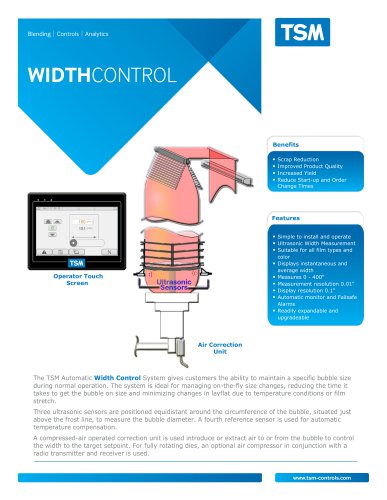

The TSM Automatic Width Control System gives you, the customer, three options for maintaining a specific bubble size during normal operation. These options are ideal for managing on-the-fly size changes, reducing the time it takes to get the bubble on size and also minimizing changes in layflat due to temperature conditions or film stretch. Options two & three, as described below, offer optimum systems for gusseted film. > Simple to install and operate Layflat or Ultrasonic measurement available > LLaayyffllaatt SSeennssoorr RReemmoottee DDiissppllaayy AAiirr Suitable for all film types and colours Displays instantaneous width and average width Automatic monitor and failsafe alarm Measures 0 - 10 meters Measurement resolution 0.1 mm Display resolution 1 mm Readily expandable and upgradeable > A single Layflat scanner houses two dynamic infra-red sensors which automatically seek and track the edges of the film irrespective of colour or thickness. > (Optional) 3 x ultrasonic sensors can be positioned around the circumference of the film, situated just above the frost line, to measure the bubble diameter. > C C onn o trr t oll o Unnii U t t (Optional) NOTE: - For fully rotating dies, an air compressor in conjunction with a radio transmitter and receiver is used. The system electronics consists simply of a single board computer with power supply and operator panel. This modular design coupled with comprehensive diagnostic software ensures that the system can be easily installed and maintained by plant personnel. The layflat width scanner is coated in a hard wearing, low friction proprietary PTFE coating, incorporating infrared edge sensors that are unaffected by film colours or ambient light. Status indicators of both width and limit sensors are included for diagnostic purposes. Both the Layflat & the Bubble Diameter Measurement system are combined to give the finest automatic width control system on the market. (Either option computes the width correct to the nearest 0.1 mm). A control action proportional to any error is initiated via the TSM Air Correction Unit. >

Open the catalog to page 1

Ultrasonic Sensor Connections TSM Layflat Width Scanner Air Correction Unit for non IBC Lines TSM Air Correction Unit TSM Width Scanner Bi-Directional Link to Supervisory Computer Remote Electronic Control > Tel: +353-42 9335560 Օ Fax: +353-42-9334422 Tel: +1-770-8866630 Օ Fax: +1-770-8862395 E-mail: info@tsm-controls.com Օ Website: www.tsmcontrols.com > TSM Reserve the right to change product specifications at any time without prior notice size="-1">

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

Width Control

2 Pages

-

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

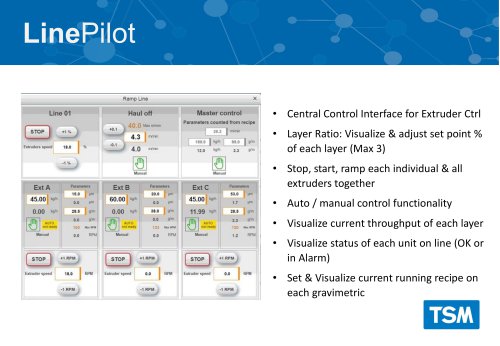

LinePilot

3 Pages

-

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

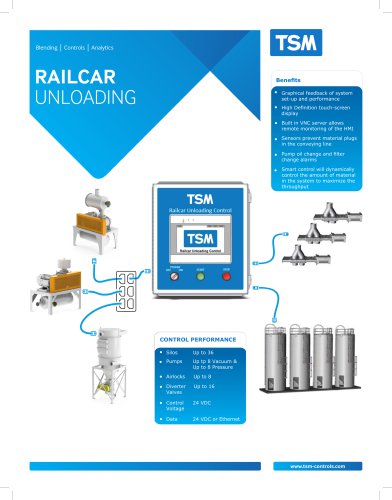

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

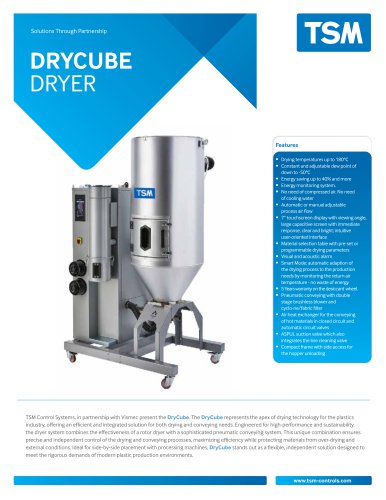

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

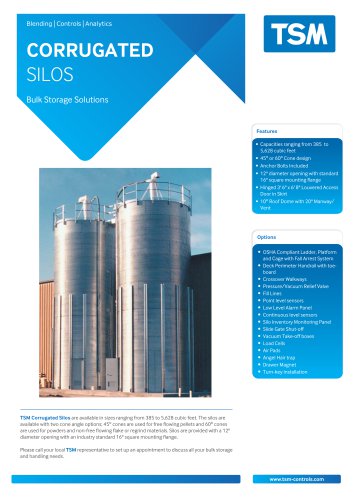

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

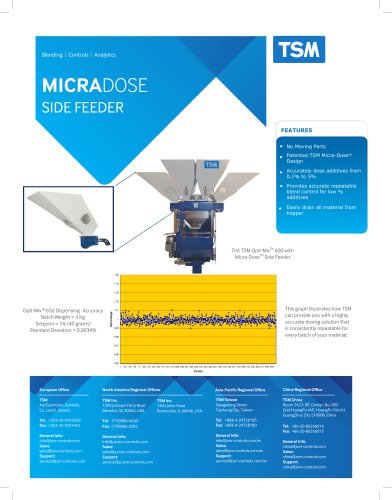

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

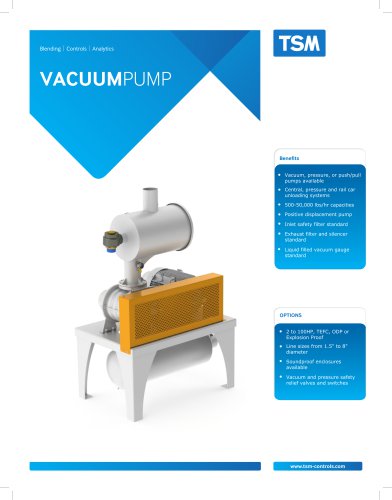

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages