Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

Specialists in Gravimetric Blending & Controls OPTIMIX-1500 Series Advanced Dosing Solutions Benefits • High Accuracy Dispensing up to 0.01% of Batch • Product Consistency • Increased Regrind Usage • Continuous Homogeneous Mixing • Faster Product Changes User Interface • Intuitive Simple Operator Functionality • Comprehensive Report! / Alarm Management • Built-in Trending & Data History Management • Industry Standard Communication Protocols • Material Usage / Inventory Statistics & Reports OPTIONS • Extrusion Control • Off-Line Blending • Regrind Flow Assist Devices • Flange Adaptors • Integrated Material Handling The OPTIMIX-1500 Series Batch Blender can accommodate up to four material components while providing throughput rates up to 1500 kg/hr. The range of blenders utilises the patented TSM slide valve design and the patented reverse-flight auger mixing technology. This combination provides superior accuracies, blend ratios and mixing homogeneity that is not achievable by competitive systems. All components are blended by weight based on the preset blend ratios on the microprocessor controller. Each component is metered separately into a single weigh hopper, which measures and controls their

Open the catalog to page 1

Specialists in Gravimetric Blending & Controls EASY- DRAIN Blender Weight Max Ambient Operating Temp Max Optional Material Temp Mix Chamber Discharge Hole European Office Ard Easmuinn, Dundalk, Co. Louth, Ireland General Info: North American Regional Office 1505 Johnson Ferry Road Marietta, GA 30062, USA. General Info: Asia-Pacific Regional Office Siangshang Street, Taichung City, Taiwan General Info: China Regional Office Huangpu Avenue (East), Huangpu District, Guangzhou City, China General Info:

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

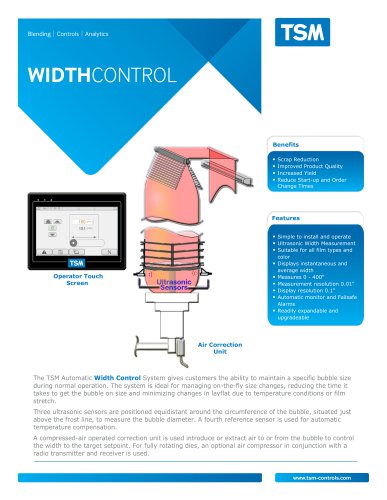

Width Control

2 Pages

-

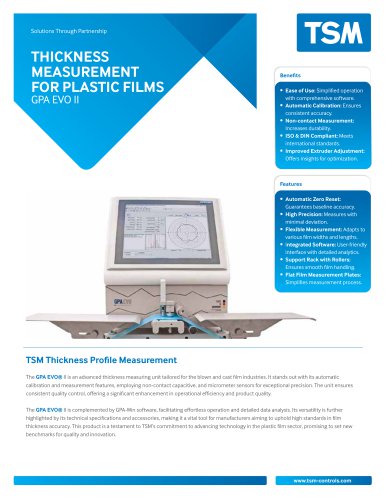

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

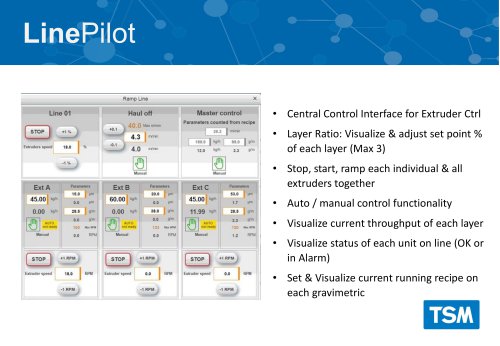

LinePilot

3 Pages

-

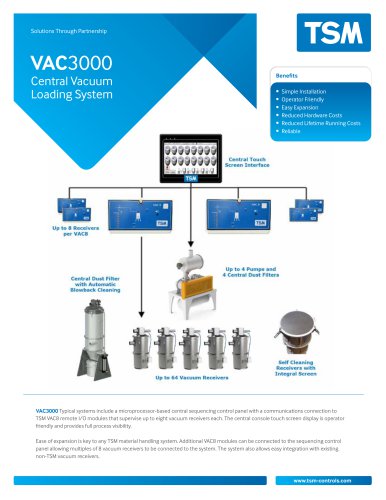

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

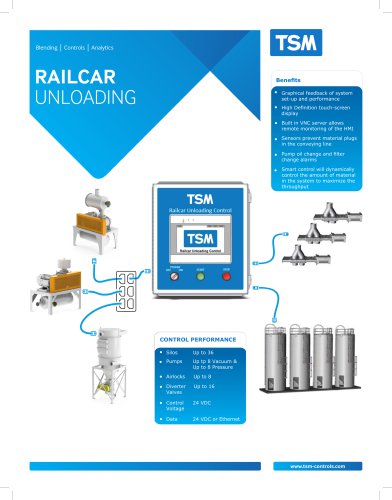

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

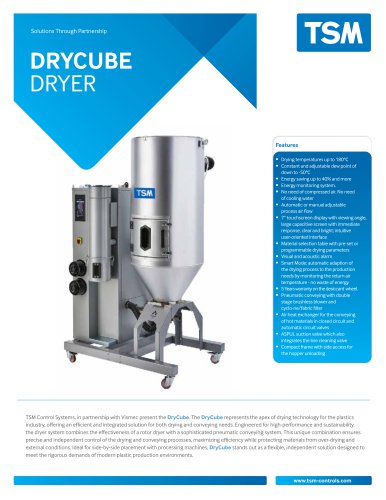

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

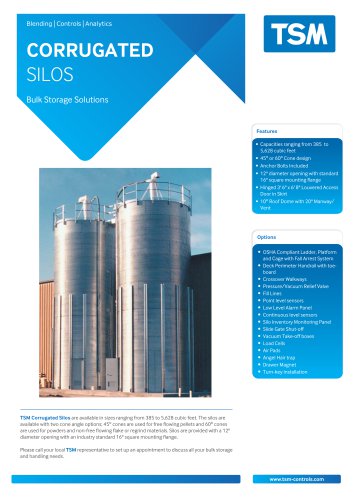

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

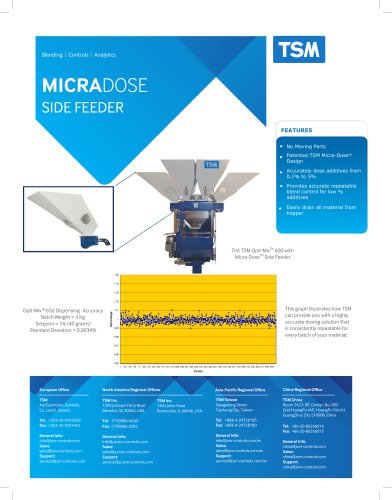

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

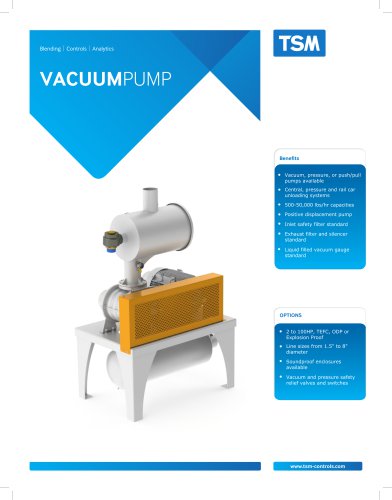

Vacuum Pump

1 Pages

-

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages