Website:

TSM Control Systems

Website:

TSM Control Systems

Catalog excerpts

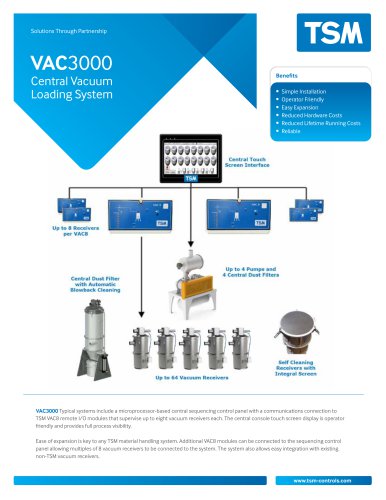

Solutions Through Partnership Central Vacuum Loading System Simple Installation Operator Friendly Easy Expansion Reduced Hardware Costs Reduced Lifetime Running Costs Reliable VAC3000 Typical systems include a microprocessor-based central sequencing control panel with a communications connection to TSM VAC8 remote I/O modules that supervise up to eight vacuum receivers each. The central console touch screen display is operator friendly and provides full process visibility. Ease of expansion is key to any TSM material handling system. Additional VAC8 modules can be connected to the sequencing control panel allowing multiples of 8 vacuum receivers to be connected to the system. The system also allows easy integration with existing non-TSM vacuum receivers.

Open the catalog to page 1

Solutions Through Partnership Central Vacuum Loading System VAC8 Remote I/O Module • Installed close to vacuum receivers to minimize wiring • Only one cable from each VAC8 to central panel • LED indicators to remotely display status of receivers and pump • Displays; filter, vacuum breaker valve, and alarms • Internal sequencing valve • Automatic blow-back for screen filter cleaning • Level switch on flapper valve • Junction box for easy connection • Simple, no-tools capacity expansion • Stainless Steel construction • Material inlet check valve for common material line applications •...

Open the catalog to page 2All TSM Control Systems catalogs and technical brochures

-

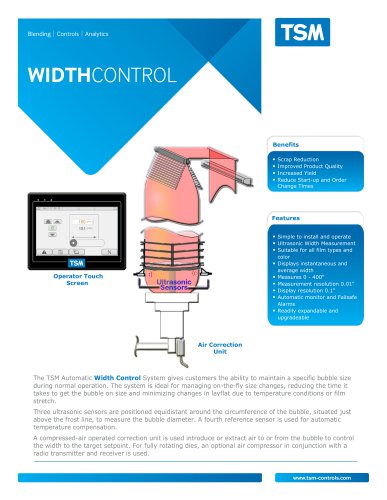

Width Control

2 Pages

-

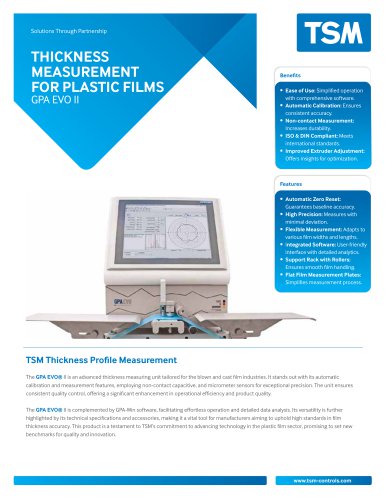

Thickness Measurement

2 Pages

-

Air Ring

2 Pages

-

LineView

2 Pages

-

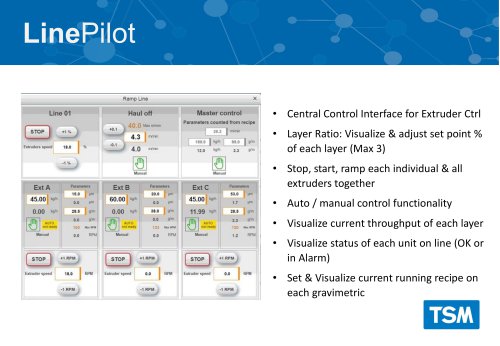

LinePilot

3 Pages

-

Vacuum Receiver

2 Pages

-

Venturi Mini Loader

2 Pages

-

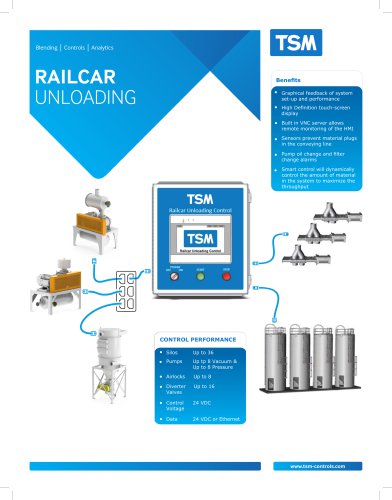

Railcar Adapter and Filter

1 Pages

-

Central Dust Filter

1 Pages

-

Automatic Unloaders

2 Pages

-

INSIGHT

4 Pages

-

TSM Material Drying

12 Pages

-

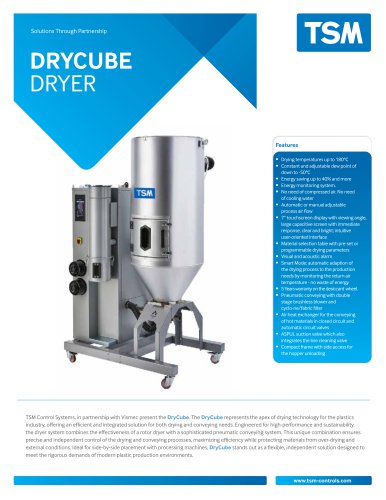

DryCube Dryer

2 Pages

-

Vertical Auger Mixer

2 Pages

-

Storage Silos

2 Pages

-

Silo Dust Collectors

8 Pages

-

Mobile Storage Bin

2 Pages

-

Angel Hair Traps

2 Pages

-

Airbrator

3 Pages

-

Blender Upgrades

2 Pages

-

Volumetric Additive Feeder

2 Pages

-

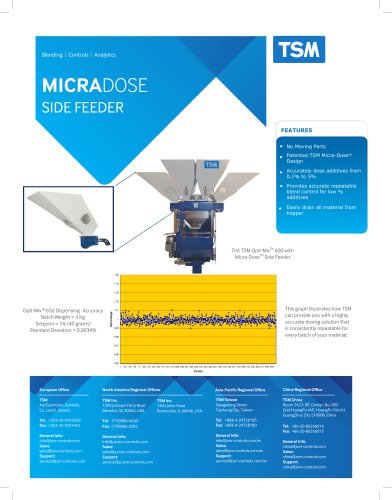

Micra-Dose Side Feeder

1 Pages

-

OPTI-X

2 Pages

-

OPTI-YIELD

2 Pages

-

TSM Gravimetric Solutions

12 Pages

-

OPTIMIX-1500 SERIES

2 Pages

-

OPTIMIX-600 SERIES

2 Pages

-

Silo Unloading System

2 Pages

-

Box Unloading Unit

2 Pages

-

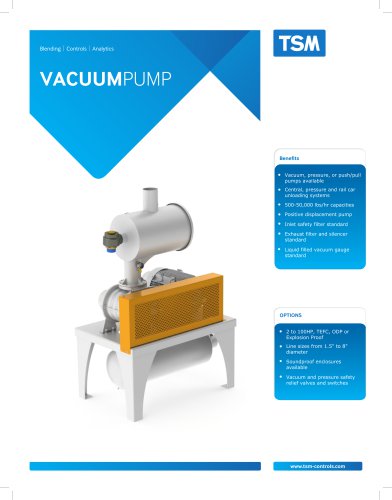

Vacuum Pump

1 Pages

-

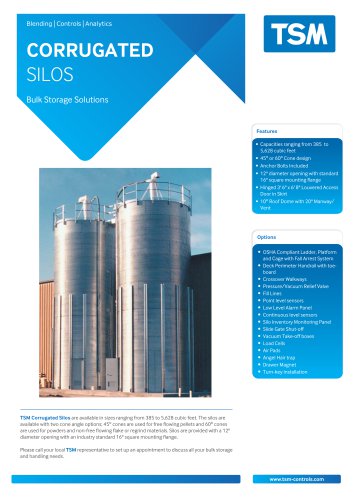

Bulk Material Silos

2 Pages

-

AUTOMATIC DEBAGGING SYSTEM

6 Pages

-

OPTI-POW

2 Pages

-

OPTI-FLAKE

1 Pages

-

OPTI-FEED

2 Pages

-

OPTIMIX MK2 3000 SERIES

2 Pages

-

OPTIMIX MK2 1000/1500 SERIES

2 Pages

-

OPTIMIX MK2 300/600 SERIES

2 Pages

-

OPTIMIX-200 Series

2 Pages

-

OPTIMIX MK2 100 SERIES

2 Pages

-

OPTI-BLEND

2 Pages

Archived catalogs

-

BOXUNLOADER

2 Pages

-

OPTIMIX 350

2 Pages

-

OPTIMIX 150

2 Pages

-

OPTIMIX 50

2 Pages

-

TSM

7 Pages

-

OPTI-MIX 3000

2 Pages

-

TSM Thickness Profiler

2 Pages

-

TSM Optimix Blender

2 Pages

-

TSM Multi-Blend

2 Pages

-

TSM Micradose Side Feeders

1 Pages

-

TSM Megabatch - Compounding

2 Pages

-

TSM Materials Handling

2 Pages

-

TSM Loaders - Receivers

2 Pages

-

TSM Extrusion Control

2 Pages

-

TSM Build Quality

2 Pages

-

TSM Blow Moulding Advantage

2 Pages

-

TSM Batch Blender Family

2 Pages

-

TSM Automatic Width Control

2 Pages

-

TSM Auto-Clean Blender

2 Pages

-

TSM (Continuous) Sigmablend

2 Pages

-

TSM 9000 Supervisory System

2 Pages

-

TSM 1000D Drybatch

2 Pages

-

TSM 100% Regrind Advantage

2 Pages

-

TSM 50-150 Batch Blenders

2 Pages