Website:

Tschritter GmbH

Website:

Tschritter GmbH

Catalog excerpts

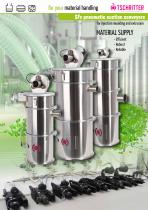

for your material handling SFx pneumatic suction conveyors SFx pneumatic suction conveyors For injection moulding and extrusion MATERIAL SUPPLY • Efficient • Robust • Relia

Open the catalog to page 1

for your material handling SFx pneumatic suction conveyors SYSTEMS AND FUNCTIONS Pneumatic conveying systems from silos to injection moulding machines or extruders – the navigation system for your feed systems • Tailored plant layout for various materials • Creation of material handling concepts for your operational processes and packaging sizes • Selection and, if necessary, redesign of individual plant components • Maximised plant availability through redundant pumps, filters and control components • Flexibility through modular hopper loaders and central filters • Easily scalable through...

Open the catalog to page 2

for your material handling SFx pneumatic suction conveyors OPTIONAL EXTRAS • • • • • • • • • • • MODEL-BASED MATERIAL HANDLING (MBM) Up to 200 separators Up to 10 vacuum circuits Up to 255 I/O nodes Autom. standby function for pumps and blowers (for fault) Automatic pump start function Touch display 4”, 7”, 10” or 12” with housing and PSU Connection of automatic coupling stations and material flow tracking Separator can be connected between conveying circuits Backup PLC for maximum fail-safety and plant availability Security Made in Germany (server in Germany with SSAE-16 and ISO 27001...

Open the catalog to page 3

for your material handling SFx pneumatic suction conveyors MATERIAL SOURCES Material handling begins with storage of the bulk goods and their incorporation in the feed system. We pay great attention to selecting the right silos, hoppers, loading stations and components for each specific application and material, as these are especially important for an optimised material flow. Energy-efficient, gentle material feed are the key characteristics of the perfect, long-lived conveying system. • Silo fill-level measurement with radar sensors & ultrasound • Charging controller for external silos...

Open the catalog to page 4

for your material handling SFx pneumatic suction conveyors MATERIAL DISTRIBUTION The distribution of material from silo to processing machine is our core business, in which we have accumulated know-how for more than 40 years. We support your production operation with customised coupling and switching stations. • Customised for best possible overview and handling • Reliable material distribution • Prevention of incorrect feed connections • Targeted guidance • Controller enable through Quality Management Coupling stations Material coupling stations Hand coupling stations • Customised •...

Open the catalog to page 5

for your material handling SFx pneumatic suction conveyors OPTIONAL EXTRAS As the core of a feed system, the hopper loader is especially important. Consisting of individual modules, the VHx series can be ideally matched to your plants. • Hopper loaders for injection moulding machines and extruders for suction conveyors with central blower stations • For granulate, grinds, PVC Dryblend flakes • Full flexibility through modular system BASIC EQUIPMENT • Separators from 4 to 250 litres in stainless steel • Hinged cover for easy cleaning • Pipe unions from 38 to 104 mm • Stainless steel...

Open the catalog to page 6

for your material handling SFx pneumatic suction conveyors Technical data Article Conveying capacity approx.*1 Separator Tube socket (* : Depending on blower, material and conveying distance) The material properties of Dryblend require special adaptation: • Enlarged exit openings with flap • Special PP filter You can count on our experience of more than 40 years in feed systems for extruders for door and window profile production. Feed quantities: VHx 30D (approx. 200 kg/h*), 37D (approx. 400 kg/h*), 48D (approx. 600 kg/h *PVC Dryblend) FOR GLASS FIBRE PELLETS Abrasive and scouring...

Open the catalog to page 7

for your material handling SFx pneumatic suction conveyors PUMPS/PUMP STANDS PUMP LAYOUT Our engineers look back on more than 40 years’ experience in the calculation and layout of pumps and blowers. The vacuum concept is devised individually to customer and material requirements. It takes into account, for example, the ambient outside air, height above sea level, conveying distance and the pipe diameters, feed capacity and material properties. All of this ensures the ideal material feed performance. • Drive rating from 1.2 to 30 kW • Individual pumps and blower stations • Automatic...

Open the catalog to page 8

for your material handling SFx pneumatic suction conveyors COMPACT FEED CONTROLLER Simple standard controller for small feed systems Materials handling in a control cabinet • Feed controller for 1 to 12 separators • 1 pump with bypass and prefilter • 1 emptying valve • Wall cabinet: Paint-finished steel, IP54, lightning lamp • Simple touch display for on/off, input, feed and emptying times, fault indication • PLC type: Wago 750-881 Ethernet Controller • Load section max. 5.5 kW DOL starting • Expansion to bus system controller possible Feed controller for large, spatially distributed feed...

Open the catalog to page 9

for your material handling SFx pneumatic suction conveyors OPERATION/VISUALISATION The networked feed system From the silo to the processing machine – control and monitoring of all stations. For visualisation, various operator panels (OP) are available. • Networking of all plant components (silos, dryers, dosing) • Visualisation at the processing machine or • External visualisation • Remote access/remote maintenance Company LAN network Feed controller Feed display Dryers Controller Direct dosing Controller Batch metering Controller 1 Feed system operation SGM

Open the catalog to page 10

for your material handling («) TSCHRITTER for your material handling FEED SYSTEM MODELLING Just like roads and junctions are shown on a GPS navigation system, the SFx system maps all pipe lines, couplings, distributors and machines and visualises them on the controllers display. The paths the materials take and the process air can be individually changed for each station. The operator can call up and change the same data at different stations. MATERIAL, SELECTION] Material and batch selection IlM&M HUSiPMArL* l!.-JLGi JW K Material selection with material number Material and batch selection...

Open the catalog to page 11