Catalog excerpts

LIST OF TRIPLE R INTERNATIONAL DISTRIBUTORS •TRIPLE R (HONG KONG) CORP.LTD. <HONG KONG OFFICE> ROOM 306, JOIN-IN HANG SING CENTRE, 71-75 CONTAINER PORT ROAD, KWAI CHUNG, NT., HONG KONG <SHENZHEN OFFICE> (KALARIE INDUSTRIAL (SHENZHEN) CO.,LTD.) 1F, WEARNES TECHNOLOGY BLDG., GAOXINKEJIYUAN CENTRAL ZONE, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, 518057 CHINA •THS / TOTAL HYDRAULICS SOLUTION NAM-GU, POHANG, KYUNGBUK.KOREA N0.59.CHENG KUNG ROAD, 700 TAINAN, MAILING ADDRESS : P.O.BOX 908, TAINAN, 262/75,77,79 ASEAN TOWER SUKHUMVIT PRAKHANONG-NUA, WATTANA, •SIMPLEX MARINE SERVICES PTE LTD 13 JOO KOON CRESCENT, 4TH STOREY, •TRIPLE R AMERICA CO.LTD. NORTH AMERICA & CENTRAL AMERICA •TRIPLE R AMERICA CO.LTD. 2700 DUFFERIN STREET, UNIT 86 SOUTH AMERICA •TRIPLE R OIL CLEANER SOUTH AMERICA LTDA RUA MANOEL TEIXEIRA, 41, PQ MARIA HELENA TEL: 55-11 -47425836 SUZANO-SAO PAULO BRASIL-CEP: 08683-340 FAX : 55-11 -47444587 •TRIPLE R FILTRATION (AUST) PTY LTD 521 PRINCESS DRIVE MORWELL •OM TRIPLE R INDIA PRIVATE LIMITED JUBILEE HILLS Head Office 5-11-7 Towa Adachi-ku, Tokyo 120 003 JAPAN e-mail: info@triple-r.co.jp http://www.triple-r-worldwide.com(in English) http://www.triple-r.co.jp(in Japanese) TROC(Triple R Overseas Corporation) Triple R Group - Committed to ISO14001 * scv MK Z.<BM>UV iatHG»* L-u*Hia-f v**«m urso ST.

Open the catalog to page 1

l.We support resource conservation, and continue to be a world leader of advanced filtration & separation technologies. l.The Triple R product range is diversified for applications in all industries and is manufactured to the highest worldwide standards. 1.Triple R Group employees and associates are dedicated and proactive and determined to achieve our mutual goals. Triple R believes that it is a vital duty for everyone in the world to protect our beautiful environment for present and future generations. We operate our business responsibly as a filtration & separation system manufacturer in...

Open the catalog to page 2

Reduce Reuse Recycle Triple R Group supports resource recycling technologies worldwide. Various coolants (oil/water base) Hydraulic oil, Lubricating oil (Mineral base, Incombustible) Washing fluid, Working fluid Special machines Various coolants (oil/water base) Hydraulic oil, Lubricating oil (Mineral base, Incombustible) Washing fluid, Working fluid Steel & Iron manufacturers Various coolants (oil/water base) Hydraulic oil, Lubricating oil (Mineral base, Incombustible) Washing fluid, Working fluid Triple R provides solutions for all industrial requirements Machine tools Construction...

Open the catalog to page 3

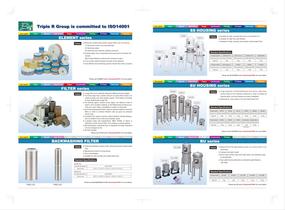

Triple R Group is committed to I S014001 Steel & Iron Paper Construction Printing E Power Generator Shipping ELEMENT series • Removes contaminants which regular filters can not remove. (1) Removes micron size solid particles (3) Removes and reduces oxidation products • Outside paper drum compresses the lower part to increase the (Multi-stage filtration protects from pressure surge.) • A non-woven sheet protects the base of the element. • Cost efficient and achieving superior results than other products. 'Please see ELEMENT series <brochure# 001 > for more details. Steel & Iron Paper...

Open the catalog to page 4

aper | Construction Printing • Compact and light model • High performance elements as standard specifications (33=929) • Removes contaminants which regular filters can not remove. (1) Removes micron size solid particles (3) Removes and reduces oxidation products • Easy maintenance Standard Specifications 'Please see OSCA series WS type <brochure# 009> for more details.

Open the catalog to page 5

i Triple filtration of the washing fluid to improve the washing (1) Removes solid particles mixed in washing fluid (2) Collects, separates, and automatically drains oil mixed in washing fluid (3) Collects and automatically drains floating oil on the surface. Photo model Specifications 'Please see TRCS series <brochure# 013> for more details.

Open the catalog to page 6

CUBE series • Fine Oil Cleaner: Combination of Fine filtration system and • Suitable for heavily contaminated fluid • Perfect fine filtration system for lubricant and fuel for large diesel engines Photo model Specifications Magnet separator Magnet separator Layout example of TRMGB210 and TRMGD100 placed on the bottom of the tank Capture heavy contaminants Capture floating contaminants 'Please see MAGNET BARRIER SYSTEM <brochure# 016> for more details.

Open the catalog to page 7

Industry: Machine tools Filtration system for gear grinding machines (model: TRAP-2OO-2F) outside dimensions: wi850xL3oooxHi9oo Standard specifications ©Heat exchanger: AKZJ907-8kw x 2 (1 each for Dirty tank: 1200L, Clean tank: 1000L) Prevents scratches (pimples) while pressing System' s functions & roles © Backwashing filter: Pre-filter when removing dusts washed away from steel plates (automatic backwashing when filters are clogged, and reuse filters.) © SS305-H114: High quality fine filtration of contaminants which backwashing filter At finished car assembling factory (steel plate press...

Open the catalog to page 8

Recommended* Target ISO Cleanliness Codes and media selection for systems using oil based uids per ISO4406:1999 for particle sized 4µ[c] / 6µ[c] / 14µ[c] Pressure < 140 bar < 2000 psi Pumps Fixed Gear Fixed Piston Fixed Vane Variable Piston Variable Vane Valves Cartridge Check Valve Directional (solenoid) Flow Control (modulating) Proportional Cartridge Valve Proportional Directional Proportional Flow Control Proportional Pressure Control Servo Valve Bearings Ball Bearings Gearbox (industrial) Journal Bearing (high speed) Journal Bearing (low speed) Roller Bearings Actuators Cylinders Vane...

Open the catalog to page 9

Typical example No.of machines Operating hours / year Machine costs / year Current availability % ~ Downtime % of which 80% caused by contaminated fluid Fluid-related downtime Labour costs for repair Total of downtime costs Fluid management can prevent 90% of the fluid-related costs Downtime caused by hydraulic faults = 35% Downtime costs Cost savings Increased machine availability to 93,08%! Remaining downtime after fluid management

Open the catalog to page 10All Triple R Europe NV catalogs and technical brochures

-

FILTER ELEMENTS

4 Pages

-

monitoring_datasheet

2 Pages

-

Wind Turbine

1 Pages

-

TR SERIES

2 Pages

-

SS SERIES

2 Pages

-

OSCA-SS SERIES

2 Pages

-

WS SERIES

2 Pages

-

Vacuum dehydrator

2 Pages

-

Quicktoron

2 Pages

-

Centrifuges

2 Pages

-

SE SERIES

2 Pages

-

BU SERIES

2 Pages

-

Triple R Filter Elements

4 Pages