Website:

TRIOPTICS

Website:

TRIOPTICS

Catalog excerpts

Highly Precise Lens Centering Measurement, Alignment and Assembly Systems

Open the catalog to page 1

LEADING TO THE FUTURE OF OPTICS Optical systems have changed the world. And they will continue to do so. TRIOPTICS is significantly involved in this process. We see ourselves as a solution provider for optical measurement and manufacturing systems and offer our customers the right system for their current and future applications. www.trioptics.com

Open the catalog to page 2

Introduction OptiCentric® 12 System Overview OptiCentric® 100 16 OptiCentric® 100 Series 26 anual and Automatic Alignment, Cementing M and Bonding with OptiCentric® 100 Systems 34 Software 37 Other OptiCentric® Systems

Open the catalog to page 3

The OptiCentric® product group sets the global standard for optical centering testing and manual and automated lens alignment. With an extremely high degree of lens centering measurement accuracy and integrated operation, OptiCentric® systems are indispensable in modern optics productions. Regardless of whether the sample has a small or a very large diameter, works in the visual or infrared spectral range, or must be aligned, cemented, bonded or just measured: the OptiCentric® systems are modularly designed so that the appropriate system can be chosen for the desired applications and...

Open the catalog to page 4

Advantages of OptiCentric® Systems • Highest absolute accuracy of 0.1 µm and highest resolution of the measurement head • Lens centering measurement of all types of optics, in UV, VIS and IR: spherical, aspherical and cylindrical lenses and lens assemblies • Testing of complex lens assemblies with the MultiLens software module • Fast and precise alignment processes, thanks to the OptiCentric® software module SmartAlign • Exchangeable head lenses for virtually unlimited measurement range • Measurement in reflection and transmission • Modular and integrated OptiCentric® accessories • L arge...

Open the catalog to page 5

Centering Errors of Optics Centering errors have a critical influence on the optical image quality of an imaging system. There is a centering error when the optical axis of a lens does not correspond with a given reference axis. The centering error is then the angle between the optical axis of the sample and the reference axis. An overview of typical assembly and centering errors can be found in the adjacent drawing. Surface tilt error of a spherical surface Shift of a lens Tilt of a lens Cementing errror Tilt of the aspherical axis Center thickness and air gaps are not correct OptiCentric...

Open the catalog to page 6

Applications Application Overview – Measuring Single Lenses and Lens Assemblies Centering Testing of Spherical Single Lenses Centering Testing of Single Lenses without Mechanical Reference Testing of Cylinder Lenses All OptiCentric® 100 Systems are equipped with the Lens Rotation Device; no air bearing is required OptiCentric® 100 Dual or OptiCentric® 3D 100 Dual, with one or two gauges depending on reference An OptiCentric® 100 System with CylinderCheck Upgrade, depending on application OptiCentric® 100 Dual or OptiCentric® 3D 100 Dual with AspheroCheck Upgrade Centering Testing of...

Open the catalog to page 7

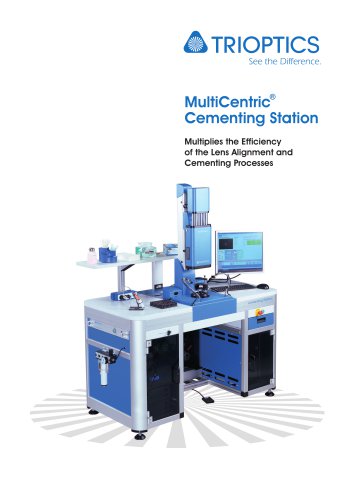

Application Overview – Aligment and Cementing of Doublets Alignment of Doublets with the with the Optical Axis of the the Bottom Lens as Reference System for Automated Edge and the Bottom Surface of Bottom Lens as Reference A utomated Version not available MultiCentric® Cementing for Lens Alignment and Cementing with respect to the optical axis Manual Lens Alignment and Cementing Equipment - A ll OptiCentric® 100 Systems, no air bearing required - Lens Rotation Device - A ll OptiCentric® 100 Systems with air bearing - Seats for Lenses - SmartAlign software module Edge processing, fastening...

Open the catalog to page 8

Application Overview – Alignment of Spherical and Aspherical Lenses on Arbor Aspherical Lenses on Arbor, Aspherical Lenses on Arbor, Reference: Air Bearing Axis Reference: Arbor Axis Assembly Manual Assembly Equipment with air bearing - Clamping device for arbor with air bearing - Clamping device for arbor - SmartAlign software module - 2 distance sensors Image quality depends on the alignment Lens After Finishing of the arbor with respect to the rotation High Image quality axis, Image quality may not be optimal • All applications are performed in reflection. • All applications can be...

Open the catalog to page 9

Application Overview – Bonding Optical System Cell axis Cell Axis All OptiCentric® 100 Systems with air bearing All OptiCentric® 100 Systems with air bearing - SmartAlign software module Upon request Upon request bonding Manual Bonding Equipment image quality All OptiCentric® 100 Systems with air bearing - SmartAlign software module quality of an existing system only be performed in two degrees of freedom - Dependent on production quality freedom - ependent on D production quality of the recess - nly the top lens O surface is aligned of the recess - Only the top lens • A ll applications can...

Open the catalog to page 10

Overview of OptiCentric® 100 Systems Centering testing and center centering testing and manual thickness/air gap measurement in one system lens alignment and assembly OptiCentric® Cementing MultiCentric® Cementing Centering testing of lenses Significant increase in efficiency For the shortest cycle times and and complex optical systems and accuracy when cementing very high accuracy when cementing with the optical axis as reference - to the optical axis - on an arbor The following combinations of the systems presented above are also available:

Open the catalog to page 11

System Overview Modular Structure of the OptiCentric® Systems Automatische Richtkitten zur optischen Achse Automatische Richtkitten auf Dorn Mechanische Spannvorrichtung kommt noch Linear stage Lens rotation device Low-coherence interferometer Visual measurement head Automatische Richtkitten zur optischen Achse Automatische Richtkitten auf Dorn Mechanische Spannvorr Tilt and translation table utomatische Richtkitten uf Dorn Mechanische Spannvorrichtung Automated lens alignment with respect to the optical axis MultiCentric ® measurement head Lower measurement head kommt noch Automated lens...

Open the catalog to page 12All TRIOPTICS catalogs and technical brochures

-

SortMaster

2 Pages

-

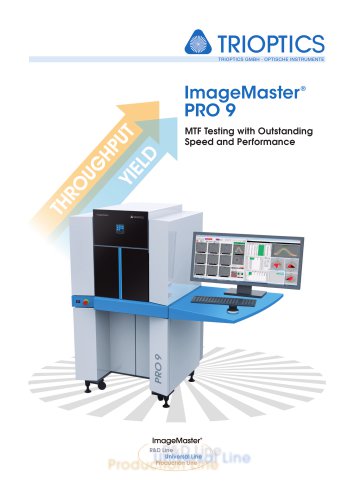

ImageMaster-MF-200-Smart

2 Pages

-

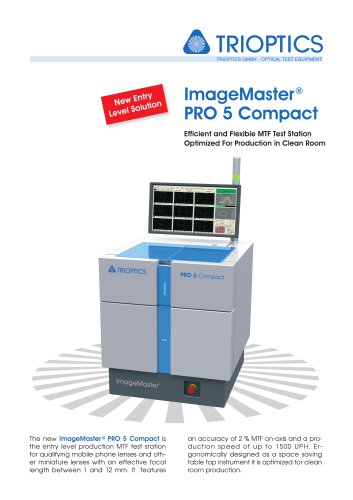

ImageMaster-PRO-5-Compact

2 Pages

-

ImageMaster-PRO-5-Ultra

2 Pages

-

ImageMaster-PRO9

4 Pages

-

ImageMaster-Universal-3D

4 Pages

-

ImageMaster-HR-2016

4 Pages

-

ATS-200

20 Pages

-

Laser Rod Test Station

2 Pages

-

OptiCentric® UltraPrecision

8 Pages

-

triangle

2 Pages

-

Spherometers

8 Pages

-

OptiSurf®

2 Pages

-

S p e c t r o M a s t e r

20 Pages

-

OptiSpheric

20 Pages

-

ImageMaster®

21 Pages

-

Opticentric

16 Pages

-

PrismMaster®

16 Pages

-

OPTOMATIC optical test instrument

12 Pages