Website:

TRIOPTICS

Website:

TRIOPTICS

Catalog excerpts

Alignment Turning Stations with Fully Integrated Measurement Technology

Open the catalog to page 1

ATS - Alignment Turning Station The Principle behind Alignment Turning Typical Applications for Alignment Turning Stations Vertical Design with Granite Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Aerostatic Bearing Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Integrated OptiCentric® Measuring Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 Additional Measurement Technology . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 2

ATS - Alignment Turning Station ATS – Alignment Turning Station Alignment Turning Station with Fully Integrated Measurement Technology for High-Precision Manufacturing of Mounted Lenses Increasing demands on optics precision require a close connection between manufacturing and measuring technology. Alignment turning is the future for high-precision manufacturing of mounted lenses. TRIOPTICS specializes in optical measurement technology and with its OptiCentric® centration measurement system it is a world leader. TRIOPTICS has incorporated this system into alignment turning stations from...

Open the catalog to page 3

The Principle behind Alignment Turning distance sensors while also controlling the alignment chuck. And on the other hand it is also operating software for the turning machine and has tool management features and corresponding setup and calibration routines. When designing the alignment turning station, TRIOPTICS worked closely with renowned manufacturers of turning machine components and placed the highest emphasis on quality in all components, resulting in a granite platform with three ultra-high precision aerostatic bearing axes, integrated vibration isolation and the consistent...

Open the catalog to page 4

The Principle behind Alignment Turning Fig. 2: The optical axes and the axes of the barrel coincide, lens distances are correct Then the spindle is rotated and the contact surfaces of the cell are machined with a sharp (diamond) turning tool, resulting in a precisely machined sur face of the cell, aligned parallel to the spindle axis. In addition to the outer surface of the cell, it is also possible to machine the front and rear contact surface during the turning process. To do this the turning tool is moved perpendicular to the spindle axis instead of along the optical axis. The lens is...

Open the catalog to page 5

The Principle behind Alignment Turning precisely aligned when the cell is machined on a turning machine corresponding to the optical axis of the lens. In order to achieve high accuracy TRIOPTICS has integrated additional measurement technology into its alignment turning stations, alongside the high-resolution autocollimators. These include tactile and optical distance sensors that ensure a highly accurate measurement of the relevant mechanical parameters. This means the highest precision is achieved by a gradual machining process, in which the cell accuracy is checked after each machining...

Open the catalog to page 6

Applications Typical Applications for Alignment Turning Stations The alignment turning procedure has a very broad range of applications, from the smallest lenses used in microscope objectives through to lenses for i-line steppers. The ATS 200 and ATS 400 alignment turning stations allow the manufacturing of almost all types of mounted lenses: • Lenses for stepper objectives • Lenses for microscope objectives and endoscope optics • Mounted infrared lenses for safety applications • Machining mounted aspherical lenses • Lenses and components for high-quality digital camera objectives • Lenses...

Open the catalog to page 7

ATS 200 ATS 200 Manufacturing Mounted Spherical, Aspherical and Infrared Lenses with up to 200 mm Diameter The ATS 200 was developed with the aim of simplifying the alignment turning of mounted lenses for the user. TRIOPTICS has extensive experience and patented technology for measuring the centration of lenses and objectives. Moreover, TRIOPTICS has been using high-precision air bearing spindles and linear stages for many years. The development of a proprietary alignment turning machine is therefore a logical step for the advancement of its technology. Modular Design The ATS 200 uses a...

Open the catalog to page 8

ATS 200 Vertical Design with Granite Base All stages and the machine base are made of fine porous natural granite. The compact design, optimized for stability, increases the rigidity in the machining zone and makes the ATS 200 resistant to external influences such as changes in temperature. Vibration damping of the granite base ensures insensitivity to vibrations. The vertical design of the ATS 200 was chosen for three reasons: Firstly it prevents the spindle causing a tilting moment during machining, which could reduce accuracy. Secondly, the footprint of the machine is reduced. Finally,...

Open the catalog to page 9

The alignment chuck is a crucial element in achieving high accuracy during machining. It aligns the optical axis with respect to the rotational axis of the spindle. TRIOPTICS has been producing this type of alignment chuck for some years now and right from the start of development placed the highest value on compatibility for precision machining. Alignment turning using an alignment chuck is a very simple and intuitive process. Centration errors are displayed during the entire alignment procedure. This provides the operator with reliable feedback about the alignment accuracy that is being...

Open the catalog to page 10

ATS 200 tilt and shift of the lens. Finally, the alignment chuck is adjusted to the calculated position. The automated alignment chuck is also suitable for heavy lenses thanks to its load capacity. In order to optimize the positioning speed, the motors should be attuned to the lens weight for the highest accuracy. The target accuracy to be achieved and the necessary positioning parameters can be configured in the software. Integrated OptiCentric ® Measuring Tech nology The ATS 200 is equipped with a centration measurement system from the OptiCentric® range. The autocollimator used here with...

Open the catalog to page 11All TRIOPTICS catalogs and technical brochures

-

SortMaster

2 Pages

-

ImageMaster-MF-200-Smart

2 Pages

-

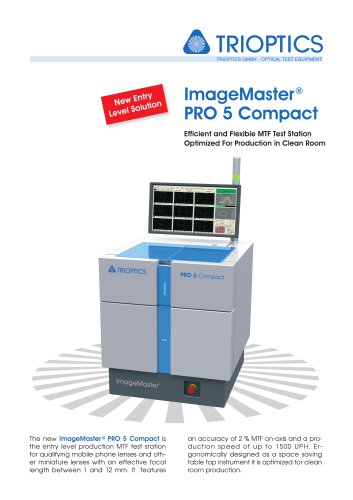

ImageMaster-PRO-5-Compact

2 Pages

-

ImageMaster-PRO-5-Ultra

2 Pages

-

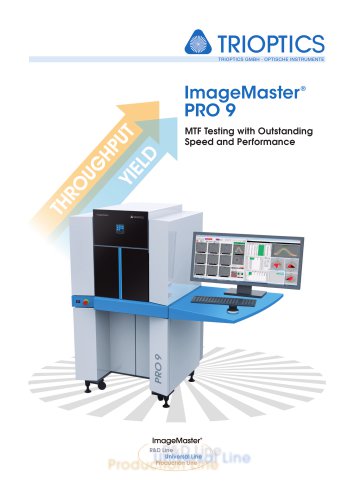

ImageMaster-PRO9

4 Pages

-

ImageMaster-Universal-3D

4 Pages

-

ImageMaster-HR-2016

4 Pages

-

Laser Rod Test Station

2 Pages

-

OptiCentric® UltraPrecision

8 Pages

-

OptiCentric® IR

40 Pages

-

triangle

2 Pages

-

Spherometers

8 Pages

-

OptiSurf®

2 Pages

-

S p e c t r o M a s t e r

20 Pages

-

OptiSpheric

20 Pages

-

ImageMaster®

21 Pages

-

Opticentric

16 Pages

-

PrismMaster®

16 Pages

-

OPTOMATIC optical test instrument

12 Pages