Catalog excerpts

Accessories: P181 PCI 208 Breakout Module P182 Additional Stepper Axis P183 Additional Encoder Axis P184 4 Axis DAC Module P185 8 Axis DAC Module P187 PCI 208 100 Way Cable 2.5m P317, P318, P319, P326, P327 CAN Modules PCI BUS PRODUCT CODE: P180 PCI 208 22 The PCI 208 is based on a 120MHz 32-bit oating point Digital Signal Processor. High speed communication over the PCI bus is provided by a 128k bit dual port RAM. A large FPGA provides up to 8 stepper axes, or 8 axes with encoder feedback, or mixtures of the two. For servo drives two optional DAC mezzanine boards provide 16 bit resolution +/- 10V outputs. A DIN rail mounting break-out board eases the wiring interconnections for low-volume applications. The PCI 208 is designed for motion control applications centred around a PC. Application programs written on the PC can access it’s facilities easily using TrioPC Motion ActiveX. It is also possible to run application programs on the PCI 208 in Trio’s multi-tasking TrioBASIC language or to use both programming techniques. FEATURE ENABLE CODES The PCI208 is supplied as standard with axis 0 and axis 1 enabled (stepper or encoder). These can be upgraded to servo axes by adding either the P184 or P185 DAC Module. Axes 2 to 7 are optionally enabled as either stepper or encoder by purchasing “Feature Enable Codes” (FECs). All enabled encoder axes can be set up as Servo by the addtion of either the 4 or 8 axis DAC Modules. In addition, “Remote Axis” FECs can be added to enable analogue feedback or CANopen servodrive support. OPTIONAL DAC MODULES MULTI-TASKING • 7 simultaneous TrioBASIC tasks The base PCI 208 has 2 stepper / encoder axes and the axis count can be increased in single axis steps up to 8. A P184 or P185 DAC board is required for analogue output servo operation. AXIS CONFIGURATION Axis 0 - 1 stepper / servo / encoder / CAN / Analogue Axis 2 - 7* stepper / servo / encoder / CAN / Analogue Any unused axis can be used as a virtual axis *Extra Axes can be added by P182 and P183 The P181 is an optional “Breakout” module for le the PCI 208 can be used to ease the task of making connections to the 100 way PCI 208 08 connector. For some simple applications, connections can be wired to a mating connector which plugs directly into the PCI 208. For series production a customised connection PCB can provide the best solution. For many other applications the breakout module is the most most s convenient solution. 4 Analogue out logue ogue 4 Analogue in lo ogue n 8 Analogue out ogue P184 P185 P18 185 The Inputs on the PCI 208 can be used as high-speed hardware registration inputs where accurate product placement in applications such as printing and packaging is required. I/O CAPABILITY • 20 24V dc inputs and 10 24V dc bi-directional channels • Additional 4 x 12 Bit analogue inputs with P184 • Expandable to 256 I/O channels and 32/16 analogue I/O channels using the P317, P318, P319, P326 and P327 modules

Open the catalog to page 1

8M BIT SRAM DUAL CAN CONTROLLERS (TRIO REMOTE I/O, DS402) 32M BIT FLASH CONNECTOR FOR P184 / P185 DAC MODULE 256K BYTE APPLICATION RAM 8 + 8 ENCODER R STEPPER TRANSCEIVERS IVERS 23 100 WAY MDR CONNECTOR OVERALL DIMENSIONS 180mm P187 - 100 way to 100 way High Density cable for connecting PCI 208 to PCI 208 Breakout Module. FIELDBUS COMMUNICATION OPTIONS CAN 21mm TrioCAN I/O, DeviceNet slave, CANopen, or user programmable 106mm EXAMPLE OF AN 8 AXIS SERVO SYSTEM WITH 256 EXPANSION I/O AND 32/16 ANALOGUE I/O PCI 208 100 WAY CABLE BREAKOUT MODULE CAN 16-OUT DIGITAL CAN 8-IN/4-OUT ANALOGUE CAN...

Open the catalog to page 2All Trio Motion Technology catalogs and technical brochures

-

Flexslice System

4 Pages

-

MC4N-RTEX Mini RTEX Master

2 Pages

-

PC-MCAT 64

2 Pages

-

MC664 / MC664-X

4 Pages

-

MC508

2 Pages

-

MC4N-Mini EtherCAT Master

2 Pages

-

UNIPLAY HMI

2 Pages

-

I/O Modules

2 Pages

-

MC302X

2 Pages

-

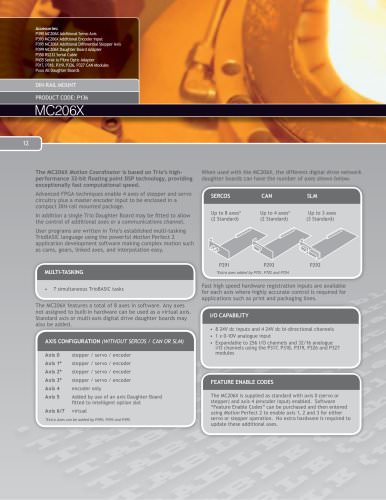

MC206X

2 Pages

-

MC464

2 Pages

-

EURO205X

2 Pages

-

EURO 209

2 Pages

-

Euro404 / Euro408

2 Pages

-

MC403 / MC403-Z

2 Pages

-

MC405

2 Pages

-

MC464

4 Pages

Archived catalogs

-

Full product brochure

17 Pages

-

Product comparison

1 Pages