Catalog excerpts

Accessories P350 RS232 Serial Cable 4 DIGITAL INPUTS INCLUDING 2 X REGISTRATION INPUTS AND 4 BI-DIRECTIONAL I/O + VOLTAGE OUTPUT AND ENABLE RELAY P315 CAN 16-I/O P325 CAN 8 Analogue Inputs CAN PORT FOR TRIO REMOTE I/O, DEVICENET SLAVE, CANOPEN OR USER PROGRAMMABLE MOTION COORDINATOR DIN RAIL MOUNT PRODUCT CODE: P192 MC302X STATUS LED’S The Trio MC302X is a compact DIN rail mounted motion controller based on Trio’s latest ARM processor technology. 2 ENCODER CONNECTIONS (6MHZ) OR DRIVE AS STEPPER OUTPUTS (2MHZ) DIN RAIL MOUNTING The MC302X has been designed to provide a compact, cost effective solution for OEM applications. The unit features two axes, the rst of which can be congured in software for either servo (with encoder feedback) or stepper control. The second axis may be either a reference encoder or a stepper axis. The differential line driver stepper outputs can be congured for simulated quadrature encoder outputs to synchronise multiple units. The built-in registration facilities make the MC302X ideal for Flying Shears, Winders, and highspeed Labellers. The MC302X is programmed using Trio BASIC which features true pre-emptive multi-tasking of up to 3 simultaneous processes. Parts of a complex application can therefore be developed, tested and run independently, although the tasks can share data and motion control hardware. Available Axis Conguration Axis 0 stepper / servo / encoder Axis 1 stepper / encoder Axis 2 virtual Each axis may run moves using linear or circular interpolation, electronic cams and gearboxes. Support is provided for continuously rotating machinery and two of the inputs may be congured for accurate hardware registration. RS232 PROGRAMMING PORT RS232 / RS485 MODBUS OR USER PROGRAMMABLE The MC302X has 8 opto-isolated 24V digital I/O (4 in, 4 bi-directional) built-in. These may be used as general purpose I/O or may be dened to be used by the controller for high speed registration, end of travel limits, datuming and feedhold functions as required. The I/O count can be expanded using Trio’s remote I/O system via the on board CAN channel up to a maximum of 256 digital and 32 analogue input channels. The MC302X has an RS232 programming port, and a user selectable RS232/485 port for peripherals such as an HMI. Built-in Communication Options CAN Trio remote I/O, DeviceNet slave, user programmable or CANopen RS232 / 485 Modbus RTU slave, or user programmable I/O Capability • 4 inputs and 4 bi-directional channels • Remote I/O expandable to 256 bi-directional channels and 32 analogue inputs. Multi-tasking • 3 simultaneous BASIC tasks

Open the catalog to page 1

Part Number P192 Size 101mm x 94mm x 48mm Weight 200g Temperature Range 0-45 degrees Celsius Power Consumption 24V @ 150mA Maximum Number Of Axes 2 + 1 Virtual Built In Encoder / Stepper (Line Driver) Bi-directional Port 2 @ 6Mhz (Encoder) or 2MHz (Stepper) Built in Analogue Outputs 1 @ +/-10V 16 Bit Resolution Servo Cycle Time 1000us, 500us, or 250us Built In Inputs 4 x 24V Opto-Isolated Built In Outputs None Built In Bi-directional I/O 4 x 24V Opto-Isolated Built in Analogue Inputs None Inputs Functions Forward Limit / Reverse Limit / Datum / F Hold Watchdog Relay 1 Solid State - 24V @...

Open the catalog to page 2All Trio Motion Technology catalogs and technical brochures

-

Flexslice System

4 Pages

-

MC4N-RTEX Mini RTEX Master

2 Pages

-

PC-MCAT 64

2 Pages

-

MC664 / MC664-X

4 Pages

-

MC508

2 Pages

-

MC4N-Mini EtherCAT Master

2 Pages

-

UNIPLAY HMI

2 Pages

-

I/O Modules

2 Pages

-

PCI 208

2 Pages

-

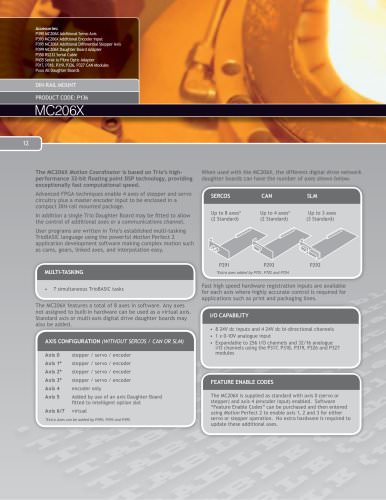

MC206X

2 Pages

-

MC464

2 Pages

-

EURO205X

2 Pages

-

EURO 209

2 Pages

-

Euro404 / Euro408

2 Pages

-

MC403 / MC403-Z

2 Pages

-

MC405

2 Pages

-

MC464

4 Pages

Archived catalogs

-

Full product brochure

17 Pages

-

Product comparison

1 Pages