Catalog excerpts

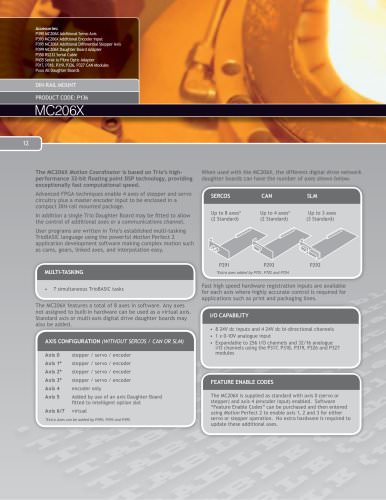

Accessories: P390 MC206X Additional Servo Axis P393 MC206X Additional Encoder Input P395 MC206X Additional Differential Stepper Axis P399 MC206X Daughter Board Adapter P350 RS232 Serial Cable P435 Serial to Fibre Optic Adapter P317, P318, P319, P326, P327 CAN Modules Pxxx All Daughter Boards DIN-RAIL MOUNT PRODUCT CODE: P136 MC206X 12 The MC206X Motion Coordinator is based on Trio’s highperformance 32-bit oating point DSP technology, providing exceptionally fast computational speed. When used with the MC206X, the different digital drive network daughter boards can have the number of axes shown below. Advanced FPGA techniques enable 4 axes of stepper and servo circuitry plus a master encoder input to be enclosed in a compact DIN-rail mounted package. SERCOS CAN SLM In addition a single Trio Daughter Board may be tted to allow the control of additional axes or a communications channel. Up to 8 axes* (2 Standard) Up to 4 axes* (2 Standard) Up to 3 axes (3 Standard) User programs are written in Trio’s established multi-tasking TrioBASIC language using the powerful Motion Perfect 2 application development software making complex motion such as cams, gears, linked axes, and interpolation easy. P291 MULTI-TASKING • 7 simultaneous TrioBASIC tasks The MC206X features a total of 8 axes in software. Any axes not assigned to built-in hardware can be used as a virtual axis. Standard axis or multi-axis digital drive daughter boards may also be added. AXIS CONFIGURATION (WITHOUT SERCOS / CAN OR SLM) Axis 0 stepper / servo / encoder Axis 1* stepper / servo / encoder Axis 4 Added by use of an axis Daughter Board tted to intelligent option slot Axis 6/7 virtual I/O CAPABILITY • 8 24V dc inputs and 4 24V dc bi-directional channels • 1 x 0-10V analogue input • Expandable to 256 I/O channels and 32/16 analogue I/O channels using the P317, P318, P319, P326 and P327 modules encoder only Axis 5 Fast high speed hardware registration inputs are available for each axis where highly accurate control is required for applications such as print and packaging lines. stepper / servo / encoder Axis 3* P292 stepper / servo / encoder Axis 2* P293 *Extra axes added by P701, P702 and P704 *Extra Axes can be added by P390, P393 and P395 FEATURE ENABLE CODES The MC206X is supplied as standard with axis 0 (servo or stepper) and axis 4 (encoder input) enabled. Software “Feature Enable Codes” can be purchased and then entered using Motion Perfect 2 to enable axis 1, 2 and 3 for either servo or stepper operation. No extra hardware is required to update these additional axes.

Open the catalog to page 1

ANALOGUE INPUT CAN PORT FOR TRIOCAN I/O, DEVICENET SLAVE, CANOPEN OR USER PROGRAMMABLE 8 INPUTS INC 4 REGISTRATION INPUTS USB (PROGRAMMING OR ACTIVEX CONTROL) 8 BI-DIRECTIONAL I/O 4 ANALOGUE OUTPUTS (FOR SERVO) PLUS 1 ENCODER INPUT RS232 (PROGRAMMING PORT) RS232 MODBUS, USER PROGRAMMABLE OR HOST LINK 13 RS485 MODBUS RTU SLAVE, HOST LINK OR USER PROGRAMMABLE E TTL PORT FOR FIBRE OPTIC ADAPTOR INTELLIGENT OPTION SLOT (FIT 1 DAUGHTER BOARD OF ANY TYPE) SD CARD 4 ENCODER CONNECTIONS (6MHZ) OR DRIVE AS STEPPER OUTPUT (2MHZ) S STATUS LEDS EXPANSION ACCESSORIES N P399 MC206X Daughter Board X d...

Open the catalog to page 2All Trio Motion Technology catalogs and technical brochures

-

Flexslice System

4 Pages

-

MC4N-RTEX Mini RTEX Master

2 Pages

-

PC-MCAT 64

2 Pages

-

MC664 / MC664-X

4 Pages

-

MC508

2 Pages

-

MC4N-Mini EtherCAT Master

2 Pages

-

UNIPLAY HMI

2 Pages

-

I/O Modules

2 Pages

-

PCI 208

2 Pages

-

MC302X

2 Pages

-

MC464

2 Pages

-

EURO205X

2 Pages

-

EURO 209

2 Pages

-

Euro404 / Euro408

2 Pages

-

MC403 / MC403-Z

2 Pages

-

MC405

2 Pages

-

MC464

4 Pages

Archived catalogs

-

Full product brochure

17 Pages

-

Product comparison

1 Pages