Website:

Trimod'Besta

Website:

Trimod'Besta

Group: Bachofen AG

Catalog excerpts

Operating Instruction Trimod Besta Level Switch - type Z...5 for use in potentially explosive atmospheres acc. to lECEx scheme Subject to technical modification Bachofen AG | Ackerstrasse 42 | CH-8610 Uster | Switzerland Phone +41 44 944 11 11 | Fax +41 44 944 12 33 info@trimodbesta.com | www.trimodbesta.com Industrial Automation

Open the catalog to page 1

Legend Information: Application hints and important information. To be followed for optimal function. Attention:Requirements and prohibitions to prevent damages, especially to material and the environment. Danger: Dangerous situation that can lead to injury and death if instructions are not followed.

Open the catalog to page 2

Safety instructions The operating manual must be read and understood before installation. If you are uncertain on any point, please contact Bachofen AG, Switzerland. The electrical connection may only be carried out by qualified personnel who have been authorised by the operator. All attached cables and cable bushings must comply with the requirements of IEC 60079-0 Appendix A – explosion-proof cables and cable entries. The supply voltage may only be applied after the cover has been closed. Please ensure that you always observe the special regulations concerning work on explosion-proof...

Open the catalog to page 3

The rated cross-section of the conductor to be considered here must be at least 0,5 mm2. Connection cables may not be bared for a distance of more than 3 mm from the terminal screw. Wire end ferrules must always be used.

Open the catalog to page 4

A 4. First close the cover and then apply the supply voltage!

Open the catalog to page 5

Maintenance Trimod Level switches must be periodically tested and cleaned, at least once annually. Procedure: 1. Before opening the housing, disconnect the supply voltage; electric shocks can be life threatening. 2. Process vessels / float chambers must be brought to atmospheric pressure before work is carried out and must be appropriately vented. If necessary, lower the fill level. If the switch is mounted in a chamber, close the corresponding shut-off valves and, depending on the requirement, empty or vent the chamber. Loosen the flange connection and remove the switch. Check the float...

Open the catalog to page 6

Loosen 2 Allan screws (Allan key 5 mm – 3/18”) on the side of the terminal block. Unscrew switch module (together with intermediate temperature piece, for ZH… and ZTD… types) from the flange module. Make sure that the O-ring seals or flat gaskets fit properly. Fit replacement module (together with intermediate temperature piece, for ZH… and ZTD… types) and tighten 2 screws. 10. Re-connect wires including grounding- and equipotential bonding connection (see connection diagram inside cover and attached switch operating instruction). 11. Energize power supply only when hinged cover is closed!...

Open the catalog to page 7

Bachofen AG | Ackerstrasse 42 | CH-8610 Uster | Switzerland Phone +41 44 944 11 11 | Fax +41 44 944 12 33 info@trimodbesta.com | www.trimodbesta.com Industrial Automation

Open the catalog to page 8All Trimod'Besta catalogs and technical brochures

-

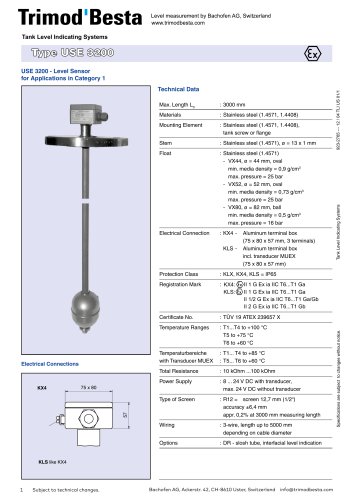

Data Sheet USE 3200

2 Pages

-

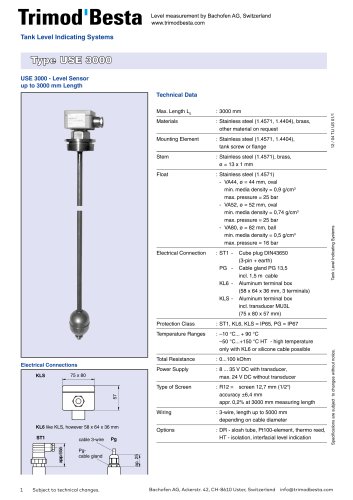

Data Sheet USE 3000

2 Pages

-

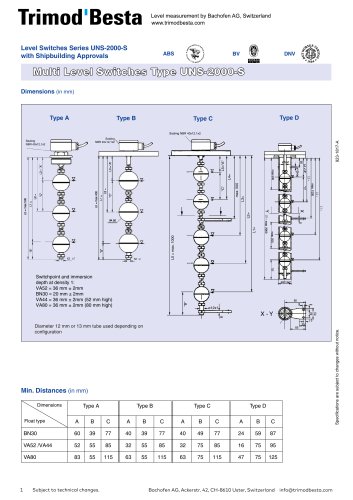

Data Sheet UNS 2000-S

2 Pages

-

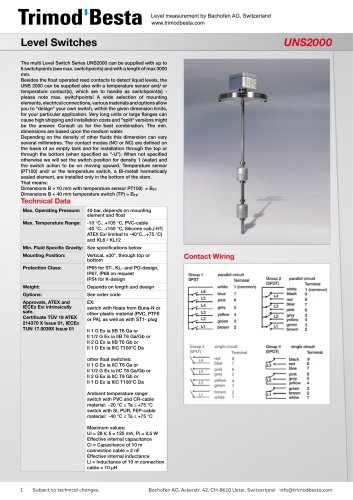

Data Sheet UNS 2000

4 Pages

-

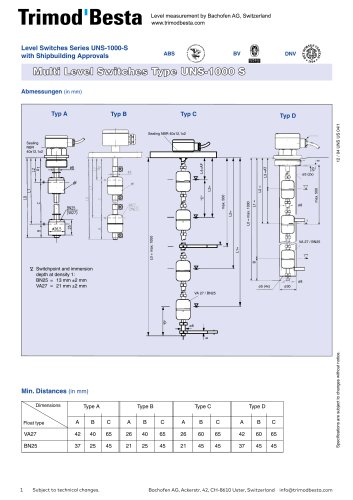

Data Sheet UNS 1000-S

2 Pages

-

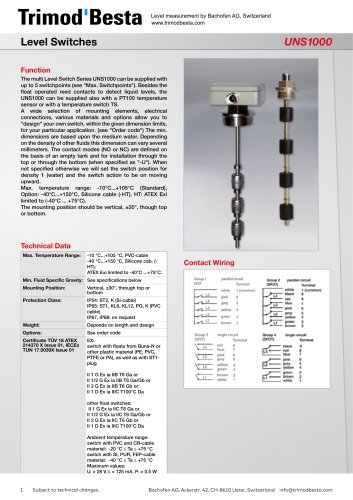

Data Sheet UNS 1000

4 Pages

-

Trimod Besta Level Switch

1 Pages

-

Specialty Switches

1 Pages

-

KARI

6 Pages

-

Trimod'Besta Catalogue

48 Pages

-

Data Sheet ELS-1100

1 Pages

-

Data Sheet LS-1900T

1 Pages

-

Data Sheet LS-74780

1 Pages

-

Data Sheet LS-1950

1 Pages

-

Data Sheet LS-7 range

4 Pages

-

Data Sheet LS-3

3 Pages

-

Data Sheet LS-1700

1 Pages

-

Data Sheet 34000E-A

1 Pages

-

Data Sheet 34000-A

1 Pages

-

Data Sheet 34000E-K

1 Pages

-

Data Sheet LS-1750

1 Pages

-

Data Sheet LS-800

4 Pages

-

LTB007X

24 Pages

-

LTB006X

28 Pages

-

LTB010X

20 Pages

-

LTB005X

20 Pages

-

LTB003X

16 Pages

-

LTB008X

24 Pages

-

Data Sheet A 01 142

2 Pages

-

LTDS03 - A 01 090

3 Pages

-

Shipbuilding solutions

8 Pages

-

BLS Level Sensor

4 Pages

-

LTDS04

2 Pages

-

LTDS02

2 Pages

-

LTDS01

4 Pages

-

Trimod'Besta Brochure

16 Pages

-

Trimod'Besta Accessories

4 Pages

-

Trimod'Besta

16 Pages