Catalog excerpts

Processes MIG (GMAW) Welding Description Robotic, MIG (GMAW) Welding Peripheral TOUGH GUN™ Wire Cutter OWNER’S MANUAL Tregaskiss 2570 North Talbot Road Windsor, Ontario N0R 1L0 Canada Phone: 1-855-MIGWELD (644-9353) (US & Canada) +1-519-737-3030 (International) Fax: 519-737-2111 For more information, visit us at Tregaskiss.co

Open the catalog to page 1

Thank You for Choosing Tregaskiss Thank you for selecting a Tregaskiss product. The TOUGH GUN™ Wire Cutter you have purchased has been designed and engineered to be a reliable tool to support high production within a robotic cell. Before installing, compare the equipment received against the invoice to verify that the shipment is complete and undamaged. It is the responsibility of the purchaser to file all claims of damage or loss that may have occurred during transit with the carrier. The owner’s manual contains general information, instructions and maintenance to help better maintain your...

Open the catalog to page 2

Subject to Change - The information presented in this manual is accurate to the best of our knowledge at the time of printing. Please visit Tregaskiss.com for the most up-to-date information.

Open the catalog to page 3

SECTION 1- SAFETY PRECAUTIONS- READ BEFORE USING 1-1 Additional Safety Warnings for Installation, Operation and Maintenance READ INSTRUCTIONS Read and follow all labels and the Owner’s Manual carefully before installing, operating, or servicing the unit. Read the safety information at the beginning of the manual and each section. Use only genuine replacement parts from the manufacturer. Perform maintenance and service according to the Owner’s Manual, industry standards and national, state/provincial and local codes. NOISE can damage hearing MOVING PARTS can injure Keep away from moving...

Open the catalog to page 4

1-2 California Proposition 65 Warnings Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to cause birth defects and in some cases, cancer. (California Health & Safety Code Section 25249.5 et seq.) This product contains chemicals, including lead, known to the State of California to cause cancer, and birth defects or other reproductive harm. Wash hands after use. 1-3 Principal Safety Standards Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, is available as a free download from the American Welding Society at...

Open the catalog to page 5

SECTION 2- SPECIFICATIONS 2-1 System Components Robotic Peripheral for GMAW Welding Power Requirements: 24 VDC Air Supply: 80-100 psi For complete parts list, please see SECTION 5 - PARTS LIST

Open the catalog to page 6

SECTION 3- INSTALLATION / SET UP 3-1 Installing TOUGH GUN™ Wire Cutter WARNING: Ensure power supply is off and disconnected before proceeding. Please follow your facility’s lockout / tagout procedures. A. To Mount Wire Cutter 1. The wire cutter should be installed within the weld cell where it is clear of all tooling and convenient for the robot to access the unit. The base plate has been designed for mounting on top of the TOUGH GUN Reamer. Be sure to consider movable fixtures and the confines of the robot. 2. Attach the wire cutter base to the top of the Reamer, or other sturdy platform...

Open the catalog to page 7

WARNING: Keep hands clear of fixed blade and TCP Locator. TCP Locator Contact Tip For best cutter performance, the MIG gun should be located so that the wire to be cut is 0.03” - 0.06” horizontally away from the fixed blade. Fixed Blade The finished wire cut length is the vertical distance from the contact tip to the bottom of the fixed blade. NOTE: Gun and nozzle not shown in diagram. 3-5 Programming Events Sequence 1. Program the robot to position the MIG gun at a right angle to the blades. Insert the gun to the proper depth and position the wire between wire cutter blades. 2. Jog the...

Open the catalog to page 8

SECTION 4- MAINTENANCE 4-1 Replacing TOUGH GUN Wire Cutter Components WARNING: Ensure power supply is off and disconnected before proceeding. Please follow your facility’s lockout / tagout procedures. Exhaust Fitting A. To Replace the Cylinder 1. Remove the air intake and exhaust fittings from the cylinder. 2. Remove both the M6 socket countersunk head cap screws holding the fixed and moving blades, and the M3 socket head cap screws holding the backing plate. 3. Remove the M10 socket head cap screw attaching the slide to the cylinder. (Refer to Section 5 - Item 9 for M10 SHCS diagram) 4....

Open the catalog to page 9

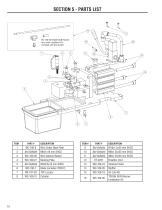

SECTION 5 - PARTS LIST WC-100-30 TOUGH GUN Reamer wire cutter Installation Kit (included with Wire Cutter) Wire Cutter Base Plate Wire Catcher Basket Backing Plate Breather Vent Solenoid Valve Blade (includes ITEM 2) TOUGH GUN Reamer Installation Kit

Open the catalog to page 10

For additional support materials such as Spec Sheets, troubleshooting information, how-to guides and videos, animations, online configurators and much more, please visit Tregaskiss.com. Scan the QR Code with your smart phone for immediate access to Tregaskiss.com/TechnicalSupport. Tregaskiss 2570 North Talbot Road Windsor, Ontario N0R 1L0 Canada Phone: 1-855-MIGWELD (644-9353) (US & Canada) +1-519-737-3030 (International) Fax: 519-737-2111 For more information, visit us at Tregaskiss.com

Open the catalog to page 12All Tregaskiss catalogs and technical brochures

-

TREGASKISS™ POWER PINS

3 Pages

-

TOUGH GUN™ TT3 Reamer

8 Pages

-

Tregaskiss™

14 Pages

-

AUTOMATION CATALOG

15 Pages

-

TOUGH GUN I.C.E

2 Pages

-

Tregaskiss Automation Catalog

13 Pages

-

Power Pins Spec Sheet

3 Pages

-

Control Plugs Spec Sheet

2 Pages