Catalog excerpts

- transcover we've got it covered! T3 TipperCover INSTALLATION MANUAL www.transcover.com Tel: +44 (0)1622 792006 Email: sales@transcover.com

Open the catalog to page 1

xl T3 Motor CODE: UMOTOR □ V Steel Rear Stop CODE: USSR Standard Mesh Tarp CODE: N/A

Open the catalog to page 2

Thank you for purchasing the Transcover T3 TipperCover Please note that the following instructions are offered as a guide to installation only and are there to assist those who are already skilled in electrical installation and material fabrication. Please do not attempt to fit this system unless you are adequately trained, accompanied, and wearing the appropriate health and safety attire. Please contact us on 01622 792006 should you require any assistance with the fitting of our product and one of our skilled installers will be more than happy to assist you with your enquiries. LOCATING...

Open the catalog to page 3

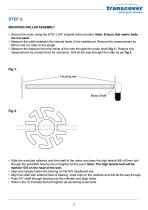

MOUNTING ROLLER ASSEMBLY • Secure the motor using the 5/16” x 3/4” imperial bolts provided. Note: Ensure that metric bolts are not used. • Measure the width betweem the internal faces of the headboard. Reduce this measurement by 50mm and cut roller to this length. • Measure the distance from the inside of the hole throught the motor shaft (fig 1). Reduce this measurement by at least 5mm for clearance. Drill all the way throught the roller as per fig 2. Fig 2. • Slide the extruded rollerbar onto the shaft of the motor and pass the high tensile M8 x 60mm bolt through the predrilled hole but...

Open the catalog to page 4

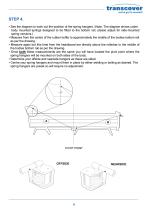

• Select the rubber buffers and rests from the kit. (Although the system can stop before the tailgate we recommend that the arm sits on rests at the rear to provide a better seal and prevent lift from the wind.) • Hold the rubber buffer against the rear stops and mark the body so that the top of the buffer is 60mm below the tailgate frame as per the diagram. • Weld the rear stops in position as per your guide markings.

Open the catalog to page 5

• See the diagram to work out the position of the spring hangers. (Note: The diagram shows under body mounted springs designed to be fitted to the bottom rail, please adjust for side-mounted spring versions.) • Measure from the centre of the rubber buffer to approximately the middle of the bodies bottom rail as per the drawing. • Measure again but this time from the headboard ear directly above the rollerbar to the middle of the bodies bottom rail as per the drawing. • Once both these measurements are the same you will have located the pivot point where the spring hangers will be mounted on...

Open the catalog to page 6

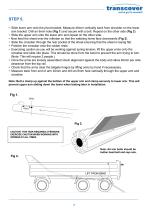

• Slide lower arm onto the pivot bracket. Measure 40mm vertically back from shoulder on the lower arm bracket. Drill an 8mm hole (Fig 1) and secure with a bolt. Repeat on the other side (Fig 2). • Slide the upper arm onto the lower arm and repeat on the other side. • Now feed the sheet onto the rollerbar so that the webbing hems face downwards (Fig 3). • Slide the crossbar through the rear pocket of the sheet ensuring that the sheet is laying flat. • Position the crossbar onto the rubber rests. • Exercising caution as you will be working against spring tension, lift the upper arms onto...

Open the catalog to page 7

WIRING (Note: We recommend the use of conduit throughout.) • Find an appropriate area along the chassis rail to mount the relay box. (Note: Consider access and use an area where the box will be protected from wheel spray.) • The back of the relay box shows the measurements between holes. Pre-drill and secure the box in place. • Route the wires to determine the switch position in the cab following the existing loom wiring. (See wiring diagram for switch configuration.) • Route the twin core wire from the bottom of the relay box to the battery but do not connect until all the wiring is in...

Open the catalog to page 8

• Retract the system to the headboard and mark where the arms land. • Mount the rubber buffers onto the marked areas for the arms to sit on when un-sheeted. • Measure back 40mm from end of the upper arm and drill all the way through and secure with bolt. Repeat on other side. • Grease bearings on hangers and roller assembly. OPERATING INSTRUCTIONS • Operate the system when the vehicle is stationary using the rocker switch in the cab. • When sheeting the vehicle let enough sheet un-roll so that the sheet lays on the load, a taught straight sheet will allow the wind to get underneath and will...

Open the catalog to page 9

Warranty on Motors Transcover offer 1 and 3 year warranties depending on the product that is purchased, it is the customers responsibility to ensure that he is aware of the products warranty at the time of purchase. Should your product be within the purchased warranty term and meet our warranty requirements Transcover will repair or replace your motor and cover delivery costs within the UK. When is The Motor Not Covered on Warranty? Warranty is void if the motor end bell has been opened - No Exception. Warranty is void if the gearbox has been cracked open - No Exception. Damage caused by...

Open the catalog to page 10

For details of our other systems and parts visit We reserve the right to change or amend instructions in our continuing development and improvement of our systems.

Open the catalog to page 11All Transcover catalogs and technical brochures

-

V-Cover-Installation

11 Pages

-

T3T TrailerCover Installation

14 Pages

-

AgriCover

1 Pages

-

DoubleCover Manual

2 Pages

-

UnderCover brochure

4 Pages

-

HyCover product range brochure

18 Pages