Catalog excerpts

TRAK TECH Traktech Construccions Mecaniques, S.L. C/ Cordova, 41 08226 Terrassa (Barcelona) Tel.(+34) 937 070 606 Fax.(+34) 937 070 717 info@traktechsl.com traktechsl.com

Open the catalog to page 1

About us Your technological partner specialized in the improvement of the productive processes related to the handling (depalletizing, unscrambling and cleaning) of empty bottles. Traktech was founded in 2010 by a team of engineers with more than 15 years of experience in the packaging sector, to fill a gap in the market of ionized air rinsers. We manufacture depalletizers, positioners, rinsers, conveyors and turnkey projects for sectors such as food, cosmetics, pharmaceuticals, beverages, etc. that cover all types of packaging (PET bottle, glass, jars, cans, PET preforms, ...). Our human...

Open the catalog to page 2

Technology Traktech invests in research and development with the aim of obtaining new systems of positioning more efficient and more compact than those existing in the market. We innovate because we understand that it is the way to offer the best solutions and to be always technologically updated. In order to offer the best options to our customers, Traktech is committed to using the latest generation solutions, as well as researching the innovations that offer the best returns to our customers. The constant investment in R + D + i makes Traktech propose creative solutions for demanding...

Open the catalog to page 3

Bottle unscramblers Linear unscrambler serie PL 1 Rotary unscrambler ROTRAK 2 Rotary unscrambler ROTRAK AAF 3 Rotary unscrambler ROTRAK and rinser SG in Monoblock 4 Depalletizer Bottle depalletizer 5 Rinsers Side Grip air rinser SG series 6 Rotary rinser R series 8 Transport systems Vacuum chain conveyors 9 Lubrication CHP dry lubrication for bottling lines 11 Conveyors for packaging Transportation systems

Open the catalog to page 4

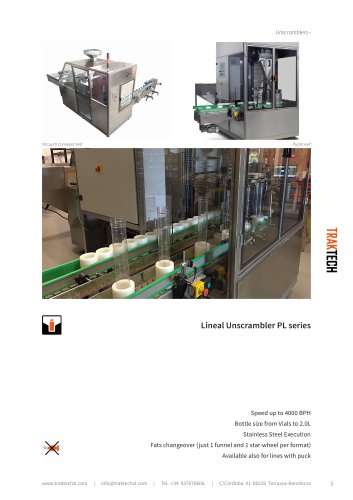

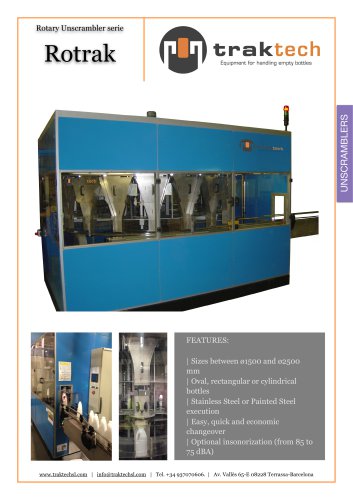

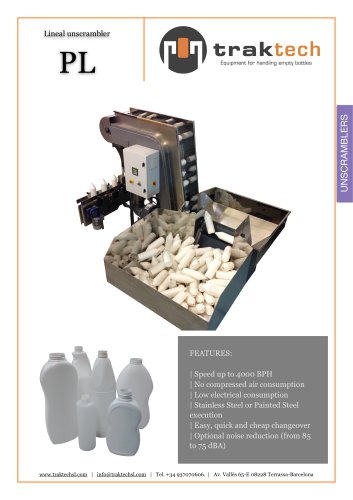

TRAKTEDH Unscrambler Linear unscrambler serie PL Our linear unscramblers PL series can reach speeds up to 4000 BPH and cover a large spectrum of bottle sizes ranging from vials to 2.0 L. The construction of the machine is in stainless steel and the format change is fast since for each format there is only one funnel and one star. The linear unscrambler series PL is also available for lines with pucks. Energy efficiency Rotary unscrambler ROTRAK The sizes of our rotary unscrambler ROTRAK range from 0800 to 03000 mm and can reach outputs of up to 18,000 BPH. They can operate with rectangular,...

Open the catalog to page 5

Rotary unscrambler ROTRAK AAF The rotary unscrambler ROTRAK AAF incorporates a novel automatic format change system through our patented AAF (Automatic Adjustable Funnel) system. The dimensions of the containers can range between Ø30 to Ø90 and with a range of heights from 120 to 310mm (for other measurements, please check). Our automatic format change system is suitable for any geometric shape of packaging and the detection of it is done by means of a vision camera. Our universal funnel is valid for any rotary unscrambler ROTRAK AAF. Model ROTRAK 1100/8 ROTRAK 1300/10 ROTRAK 1500/12 ROTRAK...

Open the catalog to page 6

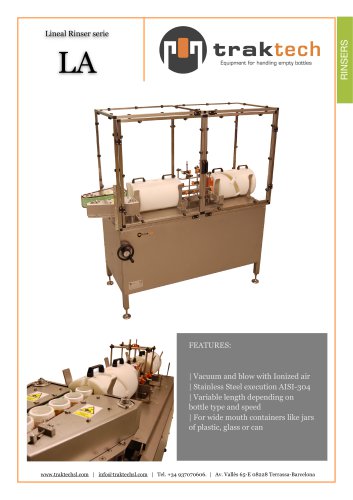

TRAKTEDH Bottle depalletizer Our depalletizers operate by bottle pushing and unloading in bulk or in line or by vacuum head and bottle discharge in line. We also have a simple version with manual loading and unloading and a configurable version for greater autonomy in depalletizing. Our depalletizers can incorporate an empty pallet accumulator as well as an automatic system for separators removal and storage. All format changes can be made at the screen. Side grip air rinser SG series The twisting of the container is made by 2 side bands (Side Grip) and the cleaning is executed below the...

Open the catalog to page 7

Twist Rinser The system of rinsing by twisting the bottles and cleaning integrated in the air conveyor by Traktech (patented system of reversing of bottles within the air conveyor) eliminates the difficult interfaces between the conveyor and the rinser and also reduces the space occupied in the production area. Our Twist rinser incorporates the IonRinseTM system (ionized and HEPA filtered blowing and vacuum) which avoids water costs and chemical residues. It is a system with minimum maintenance requirements and a very easy integration into existing air conveyors as it is a stand-alone...

Open the catalog to page 8

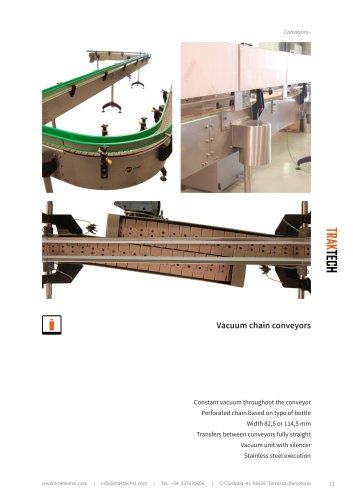

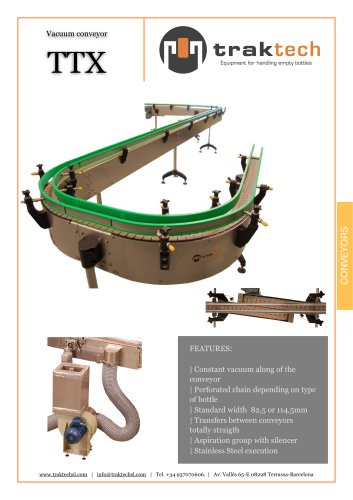

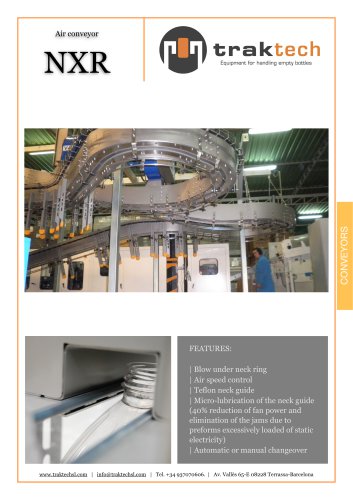

Vacuum chain conveyors Air conveyors Vacuum chain conveyors Traktech offers a constant aspiration along the entire conveyor and we use a different model of perforated hinge depending on the base of the bottle to be transported. The width of work is of 82,5mm or 114,5 mm and the interfaces between the sections of the transporter are totally straight. The vacuum unit works with a silencer and the entire conveyor is made of stainless steel. The most important characteristics of our air conveyors are: • Blowing is done under the bottle ring • We control the air flow through a variable speed...

Open the catalog to page 9

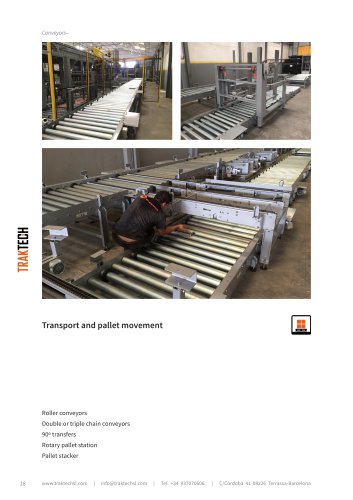

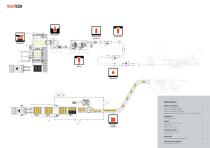

TRAKTEDH Transport systems CHP dry lubrication for bottling lines • Dry lubrication of bottling plants (chain and air conveyor) • PET, Glass, Can or Carton packaging • Dry micro-lubrication CHP: The lubricant has a Teflon concentration of up to 6% completely stable (components are not separated) and the overall system (lubricant, control system and injection) guarantees a very low lubricant consumption • DLT333® Teflon lubricant food grade H11 • Units for local lubrication, 1 line or 8 lines • Minimum guaranteed lubricant expenses Energy efficiency Transportation systems We manufacture...

Open the catalog to page 10All TRAKTECH catalogs and technical brochures

-

DELTRAK robotic unscrambler

2 Pages

-

Rotary unscrambler CONTRAK

2 Pages

-

Vacuum chain conveyors

1 Pages

-

Rotary unscrambler ROTRAK

2 Pages

-

Rotary rinser series R

2 Pages

-

Side-grip Rinser SG series

2 Pages

Archived catalogs

-

Turning and transfer units

1 Pages

-

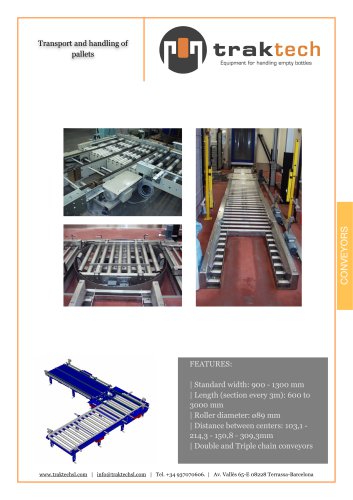

Pallets conveyors

1 Pages

-

Roller conveyors

1 Pages

-

Modular belt conveyors

1 Pages

-

PVC belt conveyors

1 Pages

-

Bulk conveyors

1 Pages

-

Air conveyors

1 Pages

-

Vacuum chain conveyor

1 Pages

-

Linear air rinser

1 Pages

-

Rotary air rinser

1 Pages

-

Twist Rinser

1 Pages

-

Rotary Unscrambler ROTRAK

1 Pages

-

Lineal unscrambler PL

1 Pages

-

Bottle Depalletizer

1 Pages

-

Pallet storage

1 Pages

-

Traktech Bulk conveyors

1 Pages

-

Traktech Venturi transport

1 Pages

-

Traktech Vacuum conveyor

1 Pages

-

Traktech Air conveyor

1 Pages

-

Traktech Unscrambler Rotrak

1 Pages

-

Traktech Unscrambler PL-10

1 Pages

-

Traktech Rinser EB-30

1 Pages

-

Traktech Rotary Rinser R

1 Pages

-

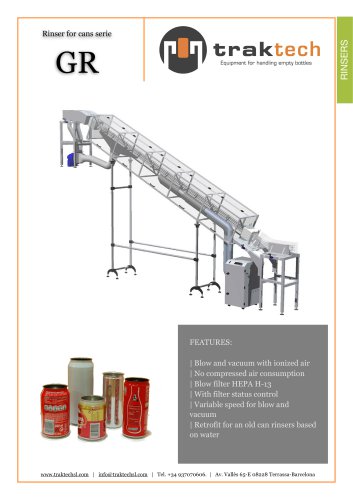

Traktech Rinser GR

1 Pages

-

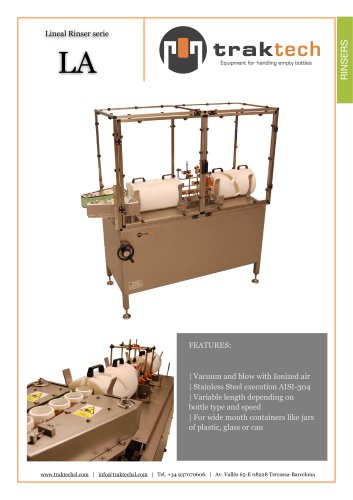

Traktech Lineal Rinser LA

1 Pages

-

Traktech Rinser SG

1 Pages

-

VENTURI TRANSPORT

1 Pages

-

VACUUM CONVEYOR

1 Pages

-

ROTARY UNSCRAMBLER

1 Pages

-

LINEAL UNSCRAMBLER PL-10

1 Pages

-

SIDE GRIPS - DEPUCKER

1 Pages

-

ROTARY RINSER

1 Pages

-

ROLLER CONVEYORS

1 Pages

-

SIDE GRIP RINSER

1 Pages

-

GRAVITY RINSER

1 Pages

-

EXTERNAL BOTTLE WASHER

1 Pages

-

PREFORM AIR RINSER

1 Pages

-

PALLET CONVEYORS

1 Pages

-

OTHER PROJECTS

1 Pages

-

FOOD CONVEYORS

1 Pages

-

BULK CONVEYOR

1 Pages

-

AIR CONVEYOR

1 Pages

-

ACCUMULATION TABLES

1 Pages

-

LINEAL RINSER

1 Pages

-

Ion-Rinse

2 Pages

-

Rollers conveyors for boxes

1 Pages

-

Belt conveyors for boxes

1 Pages