Website:

TR-Electronic GmbH

Website:

TR-Electronic GmbH

Group: TR-Gruppe

Catalog excerpts

Drill Quality Assurance BQS

Open the catalog to page 1

Drill Quality Assurance - B Q S Optional Component for Every Turning and Milling Machine Optional Component for Every Turning and Milling Machine The BQS system will reliably scan your tool or workpiece for presence and scale. It is a sensible addition to any turning and milling machine and / or all machining centres. When we developed this system, we focused primarily on our customers' requirements. Some of these requirements related to the BQS 224 Sensor, others to the compact BQS Control I / O. This optimized quality monitoring system offers you a long service life, robustness,...

Open the catalog to page 2

System Case The system case contains all necessary components for a fully functional BQS system. All components from this case are 100 % harmonized and form one complete unit. You can also order individual components from us at any time by quoting the item number. *Collet chuck Parts List: System Case (792-10006)

Open the catalog to page 3

Quality Assurance Quality Assurance Thanks to a multi-stage sealing system, TRsystems' drill quality control is capable of meeting all the requirements of classic metal processing: emulsions, lubricants, aggressive coolants, respirable dust and chips cannot harm the BQS 224 Sensor. With up to 10 million cycles, the BQS 224 Sensor offers a very long service life. The scanning wand's collet features a diameter of 1.2 mm and can be adjusted to a variable length of 165 mm max. Characteristics _ Very long service life (up to 10 million cycles) _ Multi-stage sealing concept _ Labyrinth seal with...

Open the catalog to page 4

Dimensional Drawings 110,3 97,3 paddle hole / needle bore Ø1.3 connenctor zero mark span range for collet chuck Technical Data Protection class Aluminium (anodized) Service life Scanning angle Ambient temperature Applied Standards for BQS 224 Sensor and BQS Control E / A: DIN EN 61000-4-2 Electrostatic discharge immunity test. DIN EN 61000-4-3 Radiated, radio-frequency, electromagnetic field immunity test. DIN EN 61000-4-4 Electrical fast transient / burst immunity test DIN EN 61000-4-5 Surge immunity test. Dimensions Length Weight (with tactile probe) DIN EN 61000-4-6 Immunity to conducted...

Open the catalog to page 5

benefits _ Integrated dual mode operation _ Simple handling _ Compact design _ DIN rail mounting collet _ Cable break-detection _ USB 2.0 – upgradable _ LED Display Power, OK, KO, Error _ 4 digital inputs _ 4 digital I / O (programmable) _ 12 W switching power _ Outputs are short-circuit-proof The drive actuation is implemented in a manner that is compatible with the developed control and evaluation unit. The control configuration is intuitive and easy to operate. A clearly arranged front panel shows and describes the individual connections, switches and scanners. The control unit features...

Open the catalog to page 6

Technical Data Integrated Dual Mode operation Another advantage of BQS Control I / O is the dual-mode operation. It enables to properly react to different drill bit sizes. During operation, the scanning intensity can be switched by pressing dip switch No. 4. measurement cycle testing period Examples, showing free-space monitoring (Range of movements 180°) Mode 1 - small drills and fine scanning The scanning speed in Mode 1 is lower than in Mode 2. Therefore, we have an increased precision in scanning. This mode is perfectly suitable for drill bit sizes less 3 mm. Mode 2 - quick clock cycles...

Open the catalog to page 7

BQS Control I / O – Initial Operation Test Start _ Now connect the sensor to X5/1-5: 1 = grey 2 = brown 3 = white 4 = blue 5 = black _ Connect your machine signal for the test process to X6 / 5. _ Connect the signal for the automatic teach-in process via the machine control to X6 / 4. _ Connect the outputs from which you want to read feedback as desired, X7 / 5 for OK, X7 / 4 for KO or X7 / 1 for Error. This concludes the installation. Now, the control needs to be configured. _ First of all, the power supply has to be connected to X4 / 1 GND and X4 / 2 +24 VDC. _ PWR-LED on. The digital...

Open the catalog to page 8

BSQ Control I / O - Terminal Pin Assignment X5 Configuration First of all, the DIP switches need to be set. 1. Left-hand / right-hand sensor rotation 2. Object / free space monitoring 3. Inverting the output signal 4. Mode 1: for small drills and fine scanning Mode 2: for quick clock cycles Putting into operation If these steps have been completed, the preparations for the teach-in process can begin. Using the rotary control switch to choose a sufficiently large range of movement. It is important to select an angle no larger than the observed area so the associated cycle of movement will be...

Open the catalog to page 9

Rotary encoders Absolute encoder, incremental rotary encoder, wire-actuated encoder Rotary encoders with optical and magnetic scanning function register the precise position in a wide variety of applications and industries. In medical engineering, miniature versions ensure correct positioning while SIL3-approved absolute rotary encoders provide the necessary safety. We offer not only high-quality rotary encoders (from 0 22 to 160 mm) for almost any application but also comprehensive accessories. Linear encoders Linear absolute measuring systems, laser displacement measurement Linear...

Open the catalog to page 10

Industrial PC, field bus I/O, PLC, HMI controller Consulting and implementation for new machines and retrofit Blanking and forming, systems, controls and sensors Industrial PCs are available in numerous variants and offer customized calculation power for PC-assisted automation. Programmable logic controllers (PLC) are the traditional means for automation. HMI controllers establish the interface to the user. Field bus nodes, I/O modules and cam controllers complete the range of automation components. You want to set up a largely automated new machine or retrofit and modernize your existing...

Open the catalog to page 11

TRsystems GmbH Eglishalde 16 D - 78647 Trossingen Tel. +49 7425 228 - 0 Fax +49 7425 228 - 34 info@trsystems.de www.trsystems.de Last update: 02 / 2017 68-135-024 · TRS-V-PR-GB-0001-03 Subject to technology and design modifications. Cover photo background: ©kra

Open the catalog to page 12All TR-Electronic GmbH catalogs and technical brochures

-

USB PC-Adapter HID V5

2 Pages

-

BQS 224 Sensor

2 Pages

-

BQS–Drill Quality Assurance

6 Pages

-

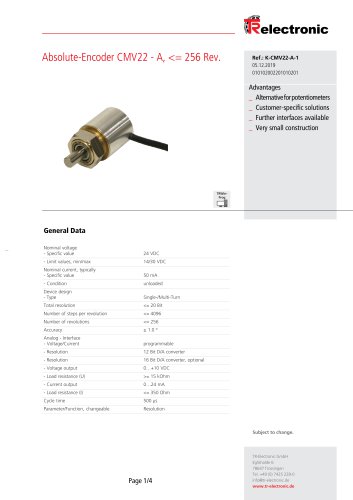

Absolute-Encoder CMV22 - A,

4 Pages

-

Sensor Highlights 2018

12 Pages

-

Wire Actuated Encoders Overview

48 Pages

-

Flyer Automation/Retrofit

12 Pages

-

Laser distance measurement

24 Pages

-

The catalog

562 Pages

-

Overview Linear Encoders

48 Pages

-

Intelligent drive technology

44 Pages

Archived catalogs

-

TRgroup

12 Pages

-

Industrial Ethernet

16 Pages

-

Profinet

4 Pages