Website:

TR-Electronic GmbH

Website:

TR-Electronic GmbH

Group: TR-Gruppe

Catalog excerpts

Team Presentation TR-Automation Retrofit your press plant from a single source Business Unit TR-Automation

Open the catalog to page 1

Release notice We expressly note that the dimensions and tolerances noted in the drawings are non-binding. Technical and design changes are reserved. They serve solely to illustrate the product. Contact our sales team for a specific offer with a binding drawing. For information and data, see www.tr-automation.com Find the information even faster: Just scan the QR code.

Open the catalog to page 2

Maroš Markovi - Fotolia Your press plant at the cutting edge of technology You would like to upgrade or modernize your press plant in a retrofit project: What you need is comprehensive specialist knowledge and many years of experience renovating and optimizing challenging press plants. As an expert for retrofit projects, the TR Automation Business Unit of the TR Group is your competent partner for modernizing and overhauling press plants. Use our extensive know-how of hydraulic and mechanical presses, blank loaders and automation systems through to cutting systems and internal high-pressure...

Open the catalog to page 4

Nataliya Hora - shutterstock © Hydraulic and mechanical presses Cutting systems _ Tryout presses _ Multicurve presses _ Transfer presses _ Press lines _ Single-action and multiple-action draw presses (ram and ram cushion, die cushion, blank holder) Blank production is the basis for the quality of the subsequent production processes, e.g. in car-body assembly in the automotive industry. The exterior skin parts particularly place high demands on the surface quality of the supplied blanks. Blank loaders The problem-free feeding of blanks is key to the production performance of the forming...

Open the catalog to page 5

Maksim Dubinsky - shutterstock Your press plant at the cutting edge of technology Automation systems Even automation systems in press plants start to get old at some point in time. With modern transfer systems, feeders, robots, blank loaders, turners and orientation stations, speedbar modules and stacking systems, which are integrated seamlessly into the overall system and tuned to function perfectly together, we ensure that your production processes experience a measurable boost in efficiency. And we can also take over the renovation of individual components or complete automation systems...

Open the catalog to page 6

industrieblick - fotolia Range of services of machine & system retrofits _ Consulting _ Recording and analysis of the actual condition _ Process optimization _ Project management _ Specifications management _ Development of specifications _ planning Project _ Risk and hazard analysis _ Construction and development of the different areas _ Electro _ Hydraulics / Pneumatics _ Mechanics _ Programming _ On-site assembly and installation _ On-site commissioning _ System-specific documentation _ of your operating and maintenance Training personnel during the handover phase _ CE marking...

Open the catalog to page 7

contrastwerkstatt - shutterstock For presses and press lines, blank loaders, automation systems, coil systems or IHU systems: to ensure smooth production processes, you need optimal-functioning electrics with control systems, sensors and actuators, convenient visualization solutions and comprehensive safety systems. TR-Automation analyzes your electrics system in the press plant to reveal any weaknesses and by modernizing specific areas ensures that the control of all of the systems functions as simply, trouble-free and efficiently as possible. Programming _ Programmable safety control...

Open the catalog to page 8

Nataliya Hora - shutterstock © _ Programmable safety control (PPS) _ Storage-programmable control (SPS) _ Sealing valves _ Sealing cylinders _ Checking/ overhauling storage _ Replacing valves and units _ Redesign of valve blocks and other components _ Cabinets and boxes: Control cabinet, engine cabinet, terminal box, industry PC, control lines, power cable, bus lines: Safetybus p, ProfiSafe, Profinet, EtherCAT, Ethernet, Profibus _ Visualization Operation and pre-selection panel (BVT), two-hand operating points, panel PC, visualization, touch-panel, operating panel, keyboard _ Sensors and...

Open the catalog to page 9

Nataliya Hora - fotolia A retrofit serves as a replacement for components that are no longer available. A process optimization can also be carried out, i.e. productivity is increased. In comparison to purchasing a new system a cost optimization also takes place, as the existing system is only upgraded and retrofitted. In many cases the machine can be used more flexibly after a retrofit. The retrofit of a machine has a higher internal acceptance, as the machines and systems are generally well known. TR-Electronic projects at a glance _ Adaptive control, ZIM-project _ Multicurve presses...

Open the catalog to page 10

Matee Nuserm - shutterstock Overview of TR-Automation references _ Airbus Deutschland GmbH, Nordenham-Einswarden _ Magnetto Automotive Deutschland GmbH, Treuen _ Allgaier AEF S.à.r.l, France _ Allgaier Werke GmbH, Uhingen _ Schuler SMG GmbH & Co. KG, Esslingen _ SMF GmbH & Co. KG, Ahlen _ BMW AG, Munich Dingolfing _ Strothmann Machines & Handling GmbH, _ Erdöl-Erdgas Workover GmbH, Salzwedel Schloß Holte Stukenbrock _ G. Siempelkamp GmbH & Co. KG, Krefeld _ ThyssenKrupp System Engineering GmbH, _ GEDIA Gebrüder Dingerkus GmbH, Attendorn _ Hörnlein Umformtechnik GmbH & Co., Schwäbisch Gmünd...

Open the catalog to page 11

Wir beraten Sie gerne: Andreas Thanassakis +49 (7425) 228 210 andreas.thanassakis@tr-electronic.de Herbert Majer +49 (7425) 228 660 herbert.majer@trsystems.de Last update: 05 / 2017 · 68-105-110 · TRS-V-PR-GB-0008-05 Subject to technology and design modifications. Cover photo background: ©kras99-fotolia.com TRSystems GmbH Business Unit TR-Automation Eglishalde 6 D - 78647 Trossingen info@tr-automation.de www.tr-autom

Open the catalog to page 12All TR-Electronic GmbH catalogs and technical brochures

-

USB PC-Adapter HID V5

2 Pages

-

BQS 224 Sensor

2 Pages

-

BQS–Drill Quality Assurance

6 Pages

-

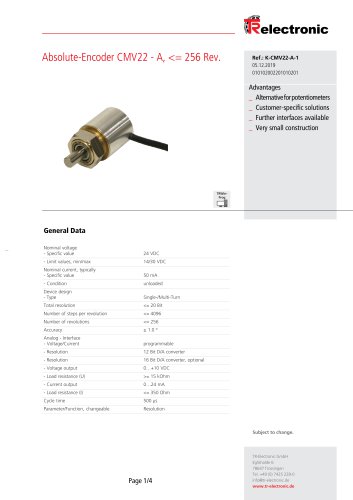

Absolute-Encoder CMV22 - A,

4 Pages

-

Sensor Highlights 2018

12 Pages

-

Wire Actuated Encoders Overview

48 Pages

-

Product Information BQS

12 Pages

-

Laser distance measurement

24 Pages

-

The catalog

562 Pages

-

Overview Linear Encoders

48 Pages

-

Intelligent drive technology

44 Pages

Archived catalogs

-

TRgroup

12 Pages

-

Industrial Ethernet

16 Pages

-

Profinet

4 Pages