Catalog excerpts

THINK PARTS THINK TORNOS TORNOS PRODUCTS Turning - Milling

Open the catalog to page 1

CT 20 THE GATEWAY TO THE TORNOS WORLD The CT 20 machine is an automatic turning machine with a sliding headstock and a bar capacity of 20 mm and 5 linear axes. It is equipped with two C axes which increase its machining capacity. The 5-axis version can take up to 26 tools (up to 10 rotating tools as an option), which makes it one of the bestequipped machines in its category on the market.

Open the catalog to page 2

Number of linear axes 5 Number of independent tool systems 2 Total number of tool positions 26 Position for rotating tools 10 Overall dimensions (LxWx H) mm 2020 x 1 256 x 1 715

Open the catalog to page 3

SWISS GT 13 / SWISS GT 26 ENDLESS FLEXIBILITY Versatile, powerful, able to work with or without guidebush and perform operations with high added value, the Swiss GT line is a solution for machining providing a complete standard equipment at a convenient price. Swiss GT line offers you a wide range of equipment and tools to increase the capabilities of the basic machine. Other accessories such as high pressure pump and independent outputs, long pieces extraction device can also complement the machine equipment.

Open the catalog to page 4

TECHNICAL CHARACTERISTICS Swiss GT 13/6 Swiss GT 13/5 Swiss GT 26/6 Swiss GT 26/5 Number of linear axes 6 5 6 5 Number of independent tool systems 2 2 2 2 Total number of tool positions 35 31 39 35

Open the catalog to page 5

SWISS ST 26 THE HIGH-PERFORMANCE SWISS TYPE LATHE The Swiss ST 26 is a highly competitive midrange machine capable of producing complex workpieces. It is equipped with unique kinematics which allow it to perform roughing finishing operations and use 3 working axes for secondary operations. The Swiss ST 26's modular tool system ensures the perfect balance between performance and efficiency. The Swiss ST 26 is available in 3 packs in order to meet customer requirements as fully as possible. Starter – advanced – Medical

Open the catalog to page 6

TECHNICAL CHARACTERISTICS Swiss ST 26 Number of linear axes 7 Number of independent tool systems 2 Total number of tool positions 37 Position for rotating tools 20 Overall dimensions (LxWx H) mm 2300 x 1 300 x 1 700

Open the catalog to page 7

SWISSNANO THE MICRO AND NANO-PRECISION SPECIALIST The SwissNano was designed to meet the demand for small workpieces requiring very high precision. For example, its kinematics enable the machine to produce two thirds of watch movement components, from the simple to the most complex, including cutting, with excellent finishes. Its capability extends beyond horological applications to include any type of workpiece requiring extreme quality and precision. The kinematic structure was designed for exemplary balance and thermal management enables the operating temperature to be achieved very...

Open the catalog to page 8

TECHNICAL CHARACTERISTICS SwissNano Number of linear axes 6 Number of independent tool systems 2 Total number of tool positions 12 Position for tool position 2 Overall dimensions (LxWx H) mm 1 800 x 650 x 1 575

Open the catalog to page 9

EVODECO THE MOST PRODUCTIVE AND POWERFUL MACHINES ON THE MARKET The EvoDECO range represents the pinnacle of Tornos products. Their unparallaled flexibility allow to efficiently produce the most complex workpieces while ensuring rapid setup change. Designed for the most demanding users, productivity (4 completely independent tool systems), performance (motorspindle offering high output and torque), both great machining autonomy and ergonomy are the assets of the EvoDECO range. They are available in 4 diameters : 10 mm, 16 mm, 20 mm and 32 mm.

Open the catalog to page 10

TECHNICAL CHARACTERISTICS EvoDEC010 EvoDEC016 EvoDECO 20 EvoDECO 32 Number of independent tool systems 4(3) 4(3) 4 4 Total number of tool positions 18(15) 20(16) 21 21

Open the catalog to page 11

MULTISWISS REVOLUTIONISING THE MULTI-SPINDLE CONCEPT Silver edition : machine for bar machining only. White edition : Chucker machine with loading systems to suit your needs. Machines can convert to bar machines. Black edition : equipped with a Y axis to broaden the range of parts. The MultiSwiss is the link between multispindle and singlespindle machines. The MultiSwiss has 6 mobile spindles which use torque motor technology to index the barrel. It is very fast and can deliver cycle times equal to those of cam-operated multi-spindle turning machines. Thanks to its hydrostatic technology,...

Open the catalog to page 12

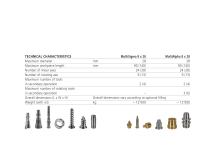

TECHNICAL CHARACTERISTICS Silver Edition White Edition Black Edition Number of independent tool systems 111 Total number of tool positions 18 18 18

Open the catalog to page 13

This range of machines is perfectly equipped to produce highly demanding parts. This complete, global high-performance solution is characterised by its high precision, easily accessible work zones, bar feeder and swarf management system. The two machines differ in terms of secondary operations : these are totally independent on the MultiAlpha, while they take place on the central slide on the MultiSigma. Both models can be equipped with up to 2 counter spindles ; on the MultiAlpha 8 x 28, these enable operation with 5 tools, each on 3 numeric axes.

Open the catalog to page 14

TECHNICAL CHARACTERISTICS MultiSigma 8 x 28 MultiAlpha 8 x 28 Maximum diameter mm 28 28 Maximum workpiece length mm 90 (140) 90 (140) Number of linear axes 24 (28) 24 (28) Number of rotating axe 9 (13) 9 (13) Maximum number of tools in secondary operation 2 (4) 2 (4) Maximum number of rotating tools in secondary operation – 3 (6) Overall dimensions (L x W x H) Overall dimensions vary according to optional filling Weight (with oil) kg ~ 12’000 ~ 12’000

Open the catalog to page 15

SAS 16.6 VERY HIGH-PRECISION CAM-TYPE MULTI-SPINDLE MACHINE Over the years, the SAS 16.6 has acquired legendary status. Extremely reliable, precise and productive, it is a very profitable machine. The low weight of the barrel allowed Tornos engineers to obtain smoother indexing thanks to the reduced inertia. Moreover, Tornos, a world leader in small-capacity multi-spindle machines, has over 70 years' experience. More than 6500 Tornos machines operate every day throughout the world. The SAS 16.6 follows on from the AS 14, SAS 16 and SAS 16 DC multi-spindle machines.

Open the catalog to page 16All TORNOS catalogs and technical brochures

-

BA 1008 HP

17 Pages

-

TISIS

16 Pages

-

Swiss GT

24 Pages

-

EvoDECO

15 Pages

-

SwissDECO

4 Pages

-

SwissNano

20 Pages

-

MultiSwiss

28 Pages

-

Swiss DT Range

13 Pages

Archived catalogs

-

BA 1008

17 Pages

-

CU 2007 / CU 3007

20 Pages

-

EvoDECO 20-32

12 Pages

-

EvoDECO 10-16

16 Pages

-

Swiss ST 26

16 Pages

-

CT 20

9 Pages

-

Robobar SBF

8 Pages

-

SAS 16.6

16 Pages

-

Brochure MultiSwiss 6x14

12 Pages

-

Brochure MultiSigma

16 Pages

-

Brochure Delta 38

4 Pages

-

Gamma 20

6 Pages

-

EvoDECO 20 / EvoDECo 32

12 Pages

-

MICRO 8/4 - MICRO 8/5

12 Pages

-

MICRO 7

8 Pages

-

SIGMA 20 / SIGMA 32

16 Pages

-

DECO 26a

16 Pages

-

DECO 20a

16 Pages

-

EvoDECO 10 / EvoDECo 16

20 Pages

-

TORNOS SOLUTIONS

20 Pages

-

bar feeder ROBOBAR MSF-832/6

8 Pages

-

Multi Spindle MULTIDECO 20/8b

20 Pages

-

Single SpindleDECO 7/10a

12 Pages

-

Product range

14 Pages